Electric driving rear axle assembly for light medium-type vehicle

An electric drive, light and medium-sized technology, which is applied to vehicle components, control devices, transportation and packaging, etc., can solve the problem that it is difficult to arrange drum-type air brakes and shock absorbers at the same time, so as to ensure driving braking and improve energy The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

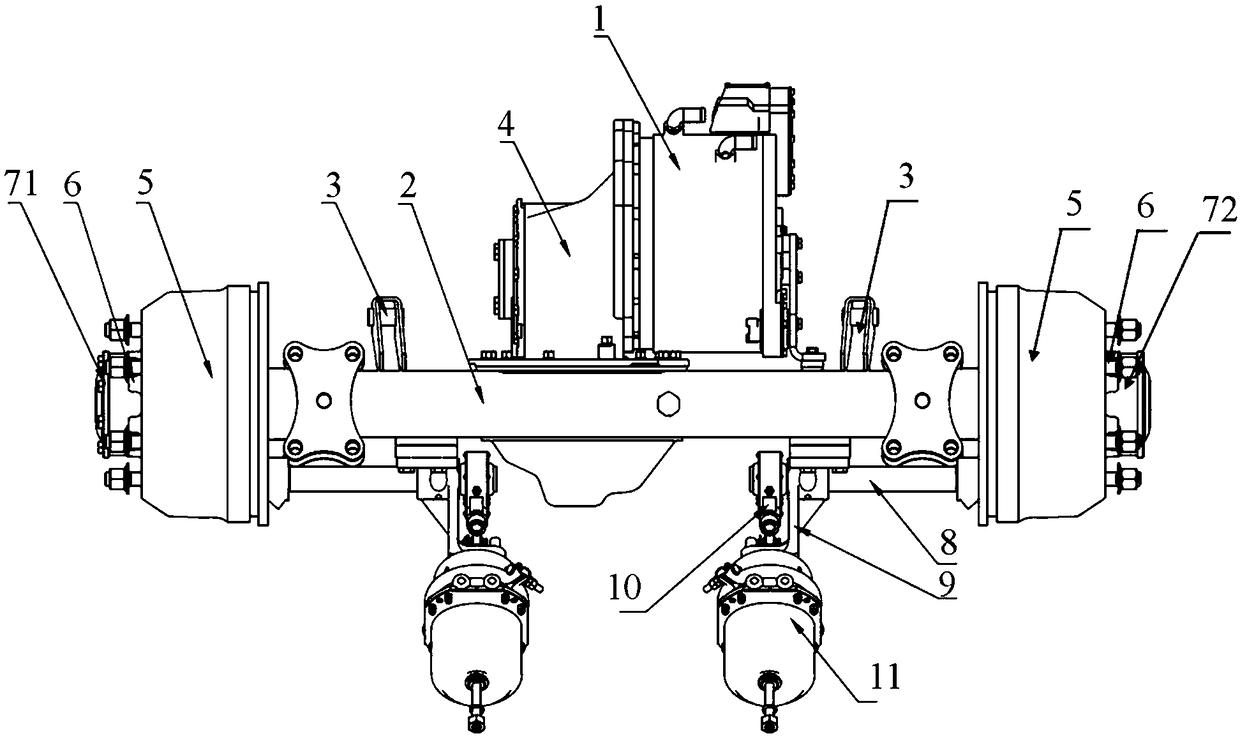

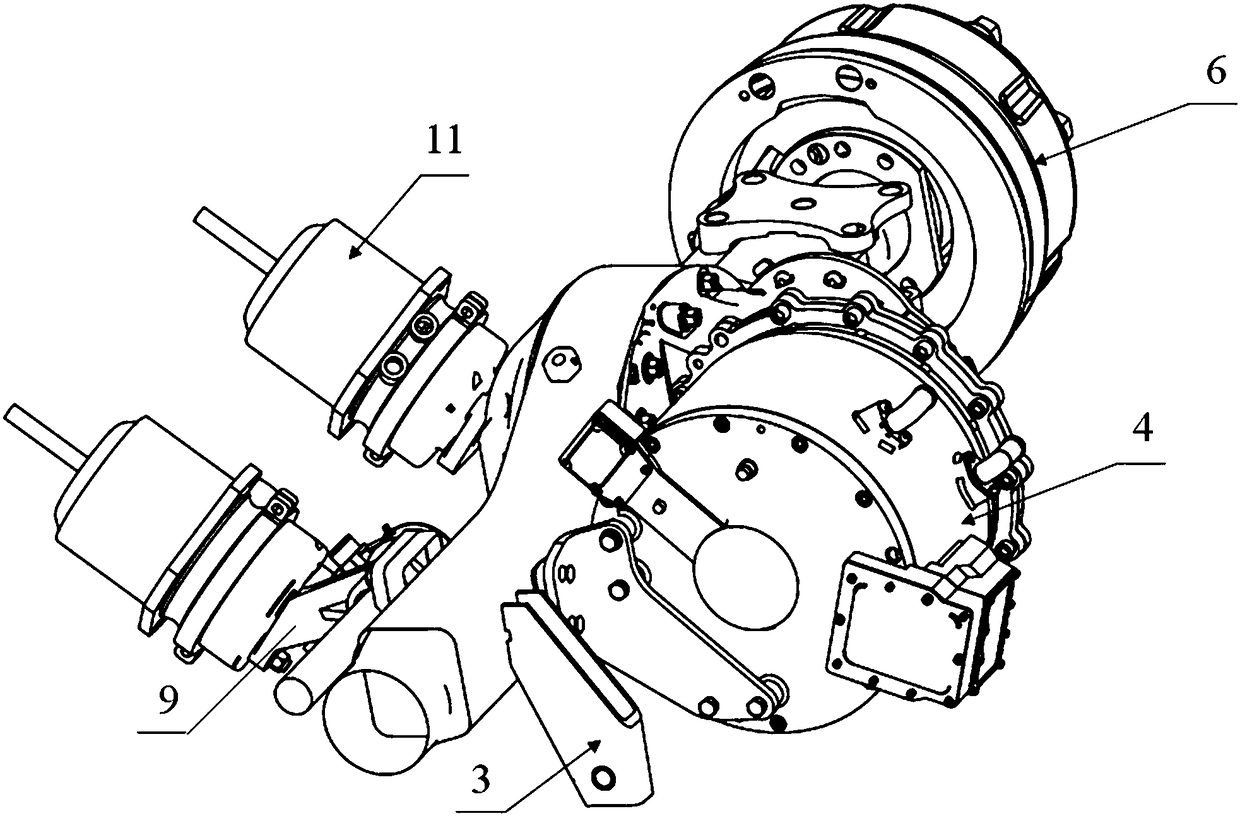

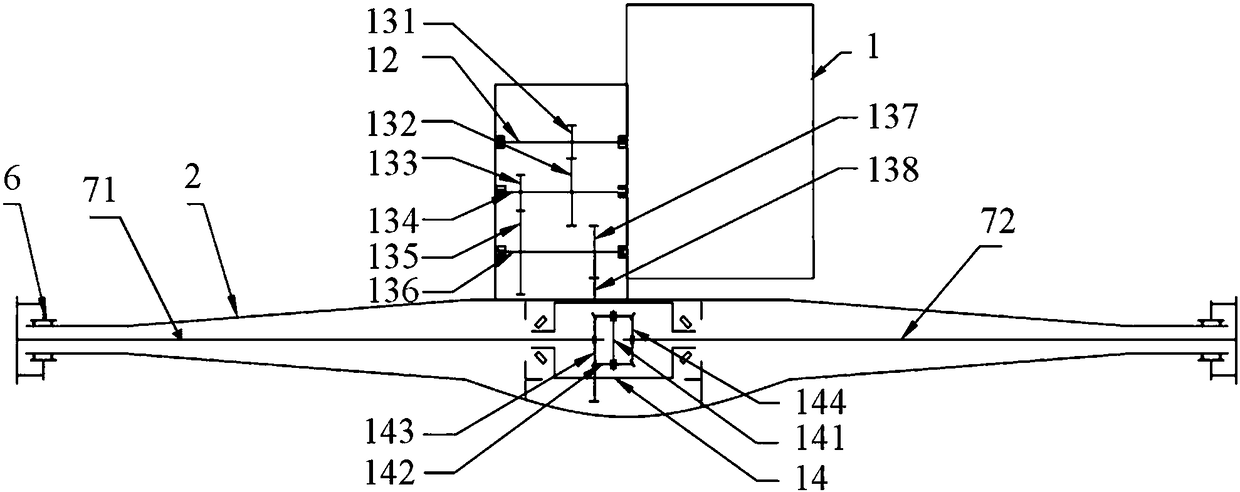

[0066] figure 1 A schematic structural view of an electrically driven rear axle assembly used in a light-to-medium-duty vehicle according to an embodiment of the present invention is shown. figure 2 A three-dimensional schematic view of an electrically driven rear axle assembly used in a light-to-medium-duty vehicle according to an embodiment of the present invention is shown. Such as figure 1 with figure 2 As shown, the electrically driven rear axle assembly includes a drive motor 1 , an electrically driven rear axle housing assembly 2 , a reducer assembly 4 and a differential assembly 14 . The axis of the drive motor 1 is parallel to but not coaxial with the wheel axis of the vehicle. In particular, the drive motor 1 and the reducer assembly 4 are independent of each other, and are not integrated in the reducer assembly 4, and the drive motor 1 and the reducer assembly 4 are detachably connected, such as with the reducer assembly 4 Connected by bolts. The drive motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com