A kind of chalcogenide optical glass and its preparation method and optical element

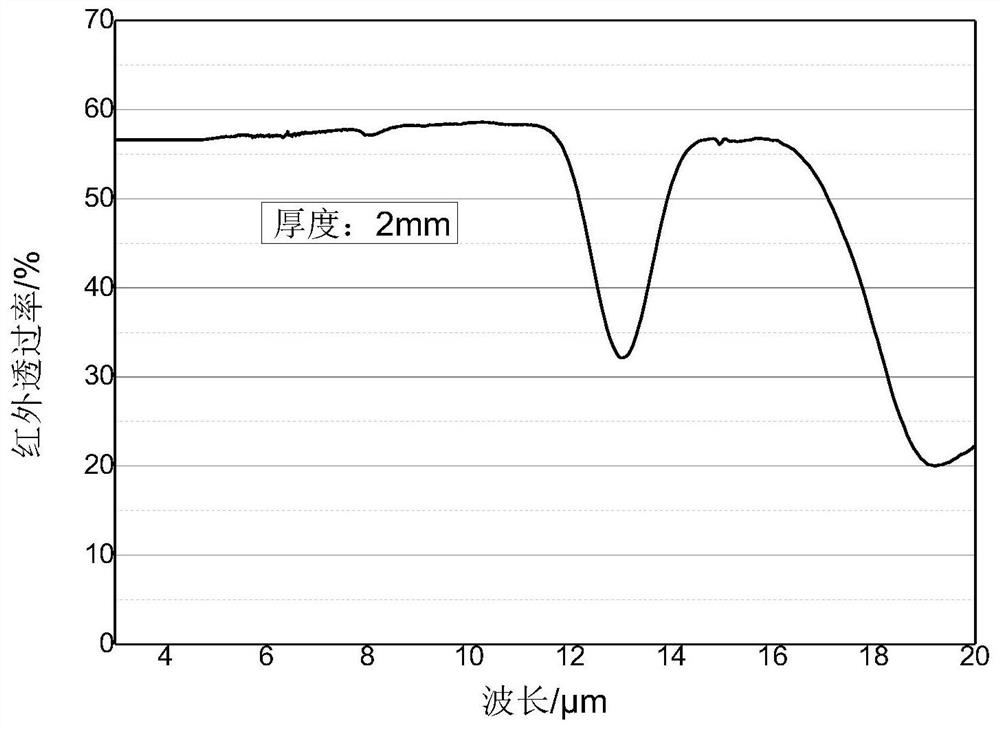

An optical glass and chalcogenide technology, which is applied to optical components, glass manufacturing equipment, glass furnace equipment, etc., can solve the problem of not disclosing the infrared transmittance glass transition temperature of chalcogenide glass, and achieve the effect of increasing the glass transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention provides a method for preparing chalcogenide optical glass according to the present invention, comprising the following steps:

[0046] 1) Ingredients and vacuum sealing: Weigh raw materials with a purity ≥ 99.999% according to the specified ratio of raw materials, and then seal the mixture in a vacuum of 10 -5 In a closed container below Pa;

[0047] 2) Melting and quenching of the mixture: place the packaged airtight container in a swing furnace for high-temperature melting, the melting temperature is 850-1100°C, and the melting time is 10-20 hours. The whole melting process is shaken to ensure that all raw materials are mixed. Evenly, when the melting temperature drops to 400-700°C, take out the airtight container and water-cool it to solidify, and form a glass semi-finished product in the airtight container;

[0048] 3) Annealing: Put the airtight container with glass semi-finished products into the annealing furnace. Remove from airtight con...

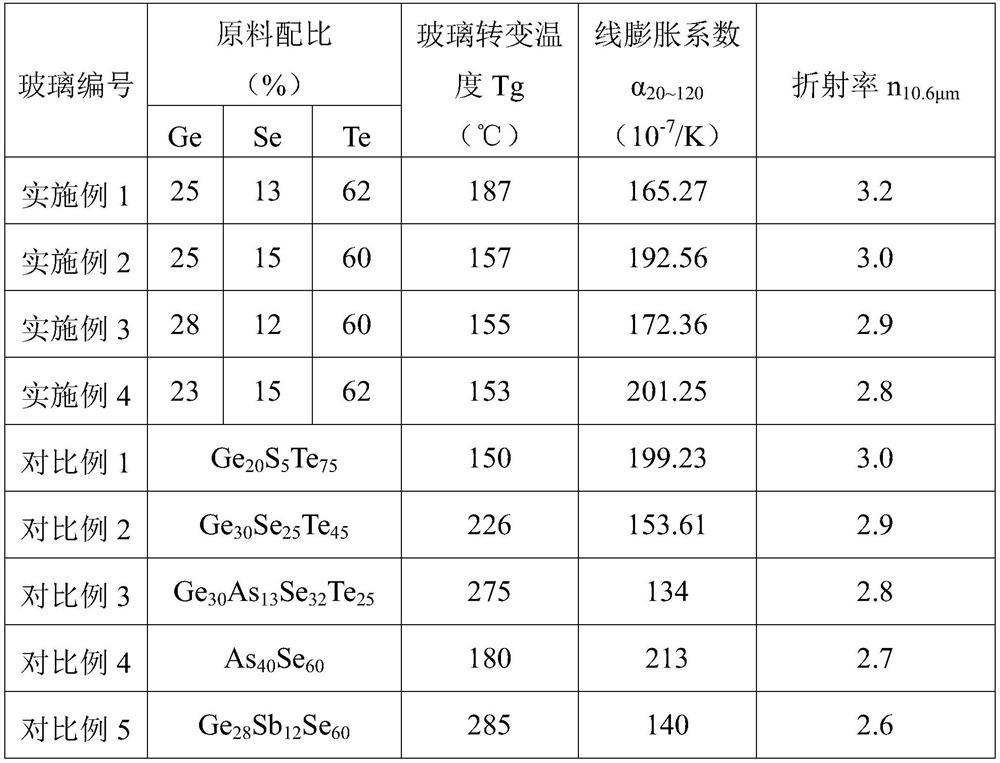

Embodiment 1~4

[0053] 1) Ingredients and vacuum sealing: according to the ratio of raw materials in Examples 1 to 4 in Table 1, take Ge, Se and Te raw materials with purity ≥ 99.999%, put them into ampoules, and evacuate to 10 -5 Pa, adopt hydrogen oxyflame to seal and airtight the ampoule bottle that compound material is housed;

[0054] 2) Melting and quenching of the mixture: Place the packaged ampoules in a swing furnace for high-temperature melting. The melting temperature is 900°C, and the melting time is 15 hours. The whole melting process is shaken to ensure that the mixture is evenly mixed. Lower to 600°C, take out the ampoule bottle and put it in water to cool and solidify, and the glass semi-finished product will be formed in the ampoule bottle;

[0055] 3) Annealing: put the ampoule containing the glass semi-finished product into the annealing furnace, the annealing temperature is 170°C, the annealing cooling rate is -10°C / h, after the temperature drops to room temperature, take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com