Cement grinding aid and applications thereof

A technology of cement grinding aids and cement, which is applied in the production of cement grinding aids and cement admixtures. It can solve the problems of poor compatibility between grinding aids and water reducers, and achieve good dispersion, optimal adsorption, and delayed dissolution- The effect of the diffusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

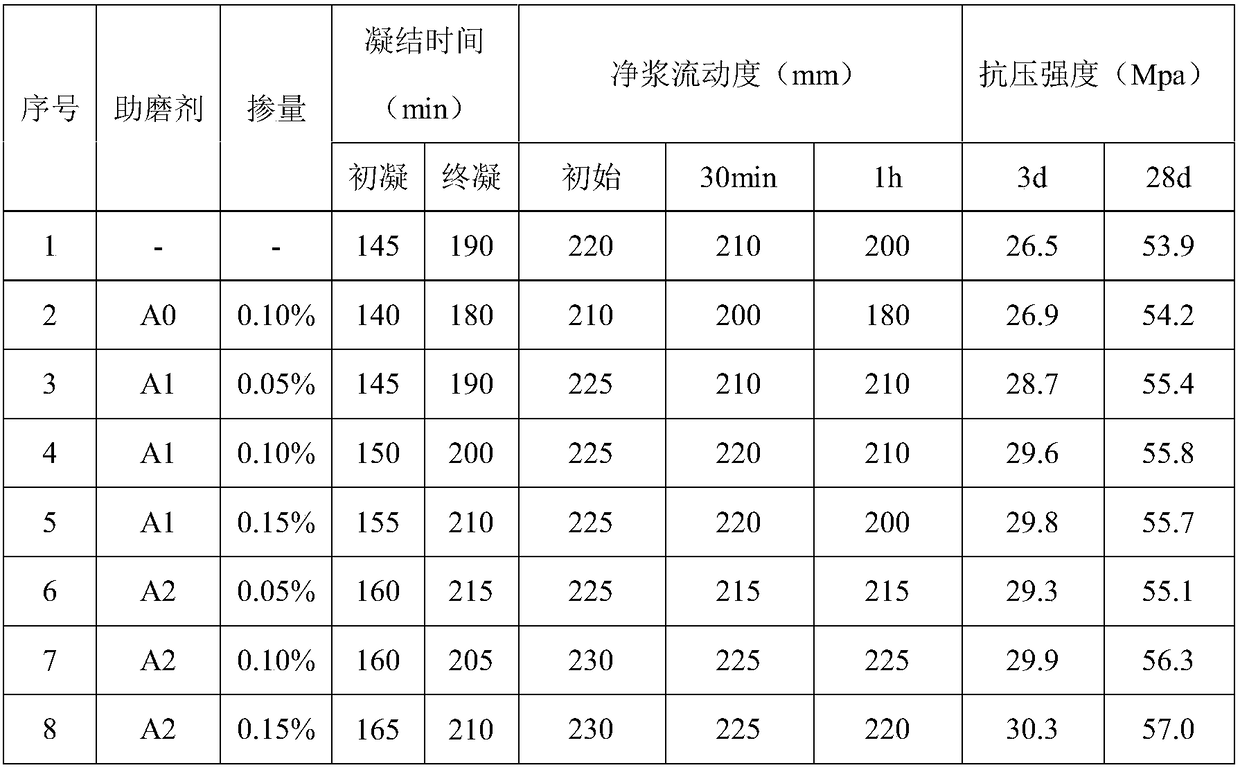

[0034] Add 11.4g of sodium sulfite and 260g of water in turn to the reaction kettle with condensing reflux, heat up to 35°C, hydrolyze at constant temperature for 30min, add 31.5g of acetone, heat up to 50°C, sulfonate for 30min, add 80.8g of triethanolamine, and then heat up to 75°C ℃, add 16.3g of formaldehyde dropwise, and control the dropping speed so that the system temperature does not exceed 85℃. With the dropwise addition of formaldehyde, the solution gradually turns purple-brown. A deep purple solution can be obtained, that is, a polymer product P1 containing polymerized carbonylated alcohol amine (the content of polymerized carbonylated alcohol amine is 35 wt%) can be obtained. According to the mass ratio: 20 parts of P1, 20 parts of dimercaptopropanol, 15 parts of sodium gluconate and 45 parts of water are formulated into grinding aid A1; 40 parts of P1, 18 parts of dimercaptopropanol, 10 parts of industrial white sugar and 32 parts Water is formulated as grinding a...

Embodiment 2

[0039]Add 7.5g of sodium metabisulfite, 5g of sodium sulfite, and 260g of water in sequence in the reaction kettle with condensing reflux, heat up to 30°C, hydrolyze at a constant temperature for 30min, add 23g of acetone, heat up to 50°C, sulfonate for 30min, add 35.4g of triethanolamine and triethanolamine 45.4g of isopropanolamine; then raise the temperature to 70°C, add 23.7g of formaldehyde dropwise, and control the rate of addition so that the temperature of the system does not exceed 85°C. With the dropwise addition of formaldehyde, the solution gradually turns purple-brown. , the temperature was raised to 95° C., the reaction was carried out at constant temperature for 3 hours, and the dark purple solution was obtained by cooling down, that is, the polymerized carbonylated alcohol amine and the polymer product P2 (the content of the polymerized carbonylated alcohol amine was 35 wt %) were obtained. According to the mass ratio: 25 parts of P2, 13 parts of dimercaptopropa...

Embodiment 3

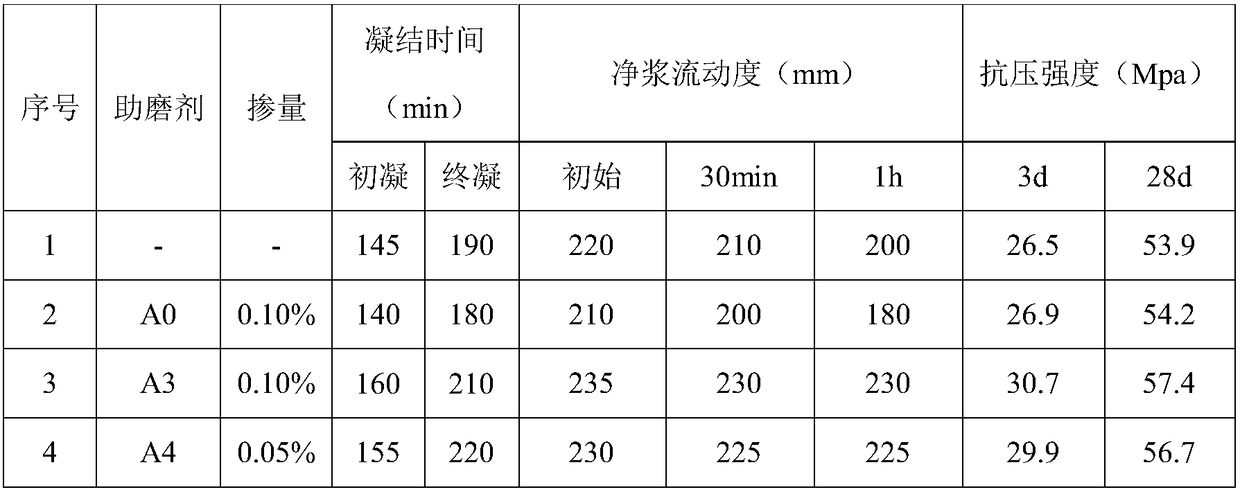

[0044] Add 8g of sodium metabisulfite, 4.4g of sodium bisulfite, and 260g of water in sequence in the reaction kettle with condensing reflux, heat up to 40°C, hydrolyze at a constant temperature for 30min, add 19.4g of acetone, heat up to 50°C, sulfonate for 30min, and add triethanolamine 37.4g and 40.8g of diethylene monoisopropanolamine, then heat up to 80°C, add 30g of formaldehyde dropwise, and control the rate of addition so that the temperature of the system does not exceed 85°C. With the dropwise addition of formaldehyde, the solution gradually turns purple-brown. After adding formaldehyde dropwise, raise the temperature to 97° C., react at a constant temperature for 4 hours, and cool down to obtain a deep purple solution, that is, a polymer product P3 containing polymerized carbonylated alcohol amine (the content of polymerized carbonylated alcohol amine is 35 wt%). According to the mass ratio: 50 parts of P3, 8 parts of dimercaptopropanol, 3 parts of sodium gluconate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com