Combined polyether, hard polyurethane foam and preparation method thereof, and water heater

A technology of rigid polyurethane and combined polyether, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as failure to meet environmental protection requirements, ozone layer destruction, etc., achieve zero ozone depletion potential, low environmental protection requirements, and thermal conductivity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The invention also provides a preparation method of rigid polyurethane foam.

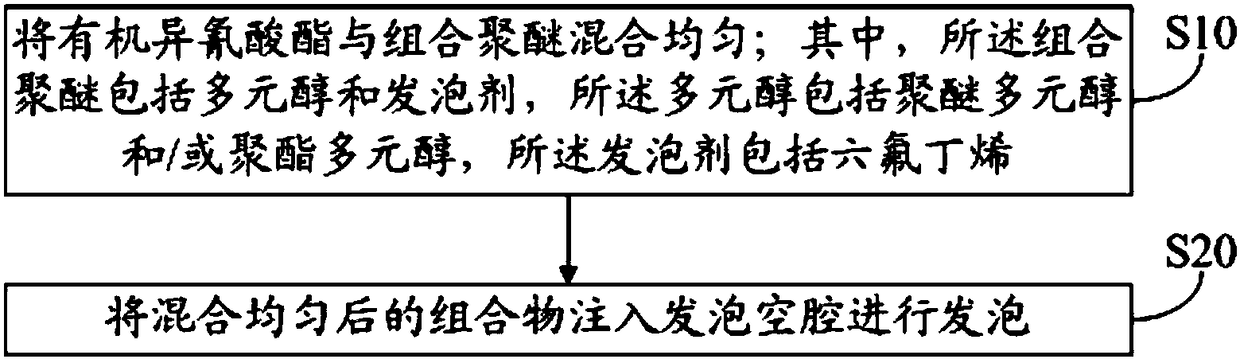

[0060] refer to figure 1 , in one embodiment of the present invention, the preparation method of this rigid polyurethane foam comprises the following steps:

[0061] Step S10, uniformly mixing the organic isocyanate and the combined polyether;

[0062] Step S20, injecting the uniformly mixed composition into the foaming cavity for foaming.

[0063] In this embodiment, the specific structure of the combination polyether refers to the above-mentioned embodiment, at least, the combination polyether includes a polyol and a foaming agent, wherein the polyol includes polyether polyol and / or polyester polyol, and the foaming agent including hexafluorobutene. In this way, the rigid polyurethane foam prepared by the preparation method of the rigid polyurethane foam of the present invention is environmentally friendly and has a low thermal conductivity, so that the water heater with the inner tank c...

Embodiment

[0071] Raw material formula: the polyether polyol A of 40 weight parts, the polyether polyol B of 6 weight parts, the polyether polyol C of 30 weight parts, the polyester polyol of 10 weight parts, the composite flame retardant of 8.5 weight parts ( DEEP and DMPP weight ratio 1:1), 0.4 parts by weight of foaming catalyst (PC-12), 1.9 parts by weight of gel catalyst (PC-8), 0.5 parts by weight of polymerization catalyst (TMR-2), 2.0 parts by weight Parts of silicon foam stabilizer, 0.7 parts by weight of water, 5.5 parts by weight of HFC-245fa, 25 parts by weight of FEA-1100, 126.69 parts by weight of PM2010 (organic isocyanate) of Yantai Wanhua.

[0072] Preparation method: pre-mix the components in the above raw material formula except organic isocyanate in a stirring pressure tank; The organic isocyanate contained in the black material working tank is injected into the water heater water tank mold with vent holes on the top through a high-pressure mixing head under a pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com