A high-performance europium, dysprosium co-doped strontium aluminate long-lasting phosphor and preparation method thereof

A phosphor and aluminum acid technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low luminous intensity, short afterglow time, and insufficient afterglow time, and achieve afterglow performance improvement, afterglow time extension, The effect of increasing the luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

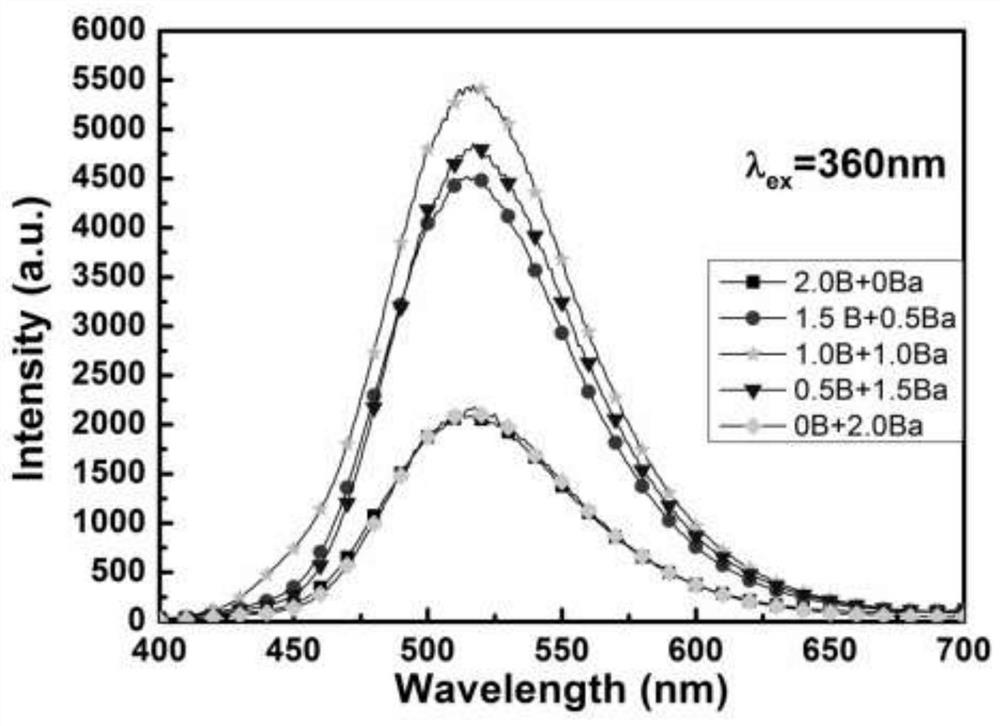

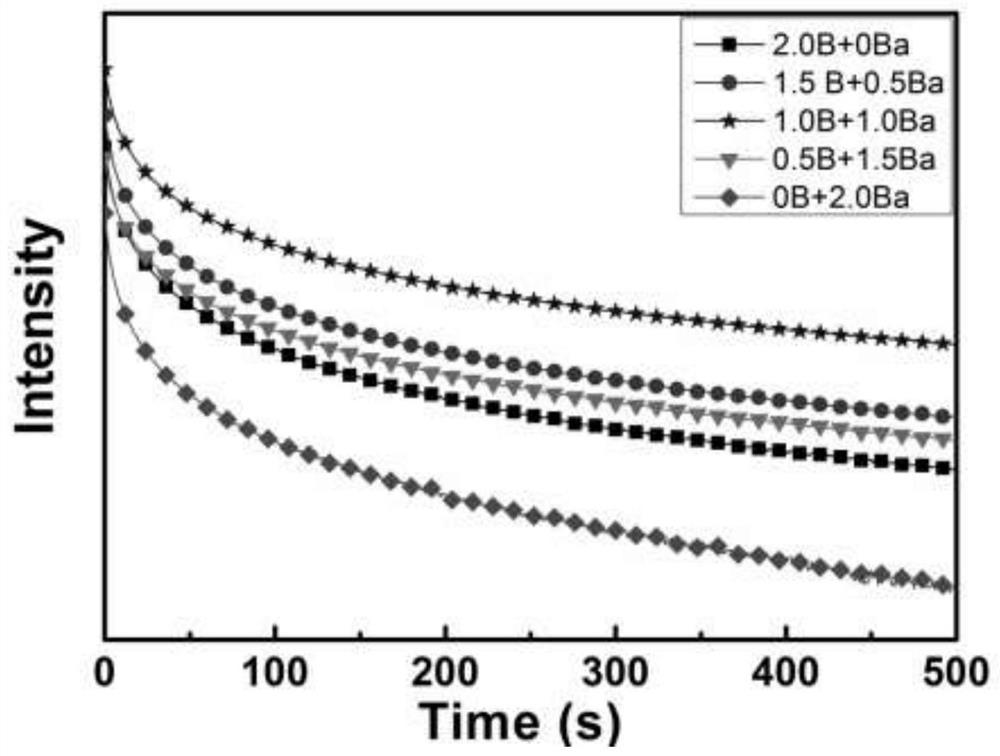

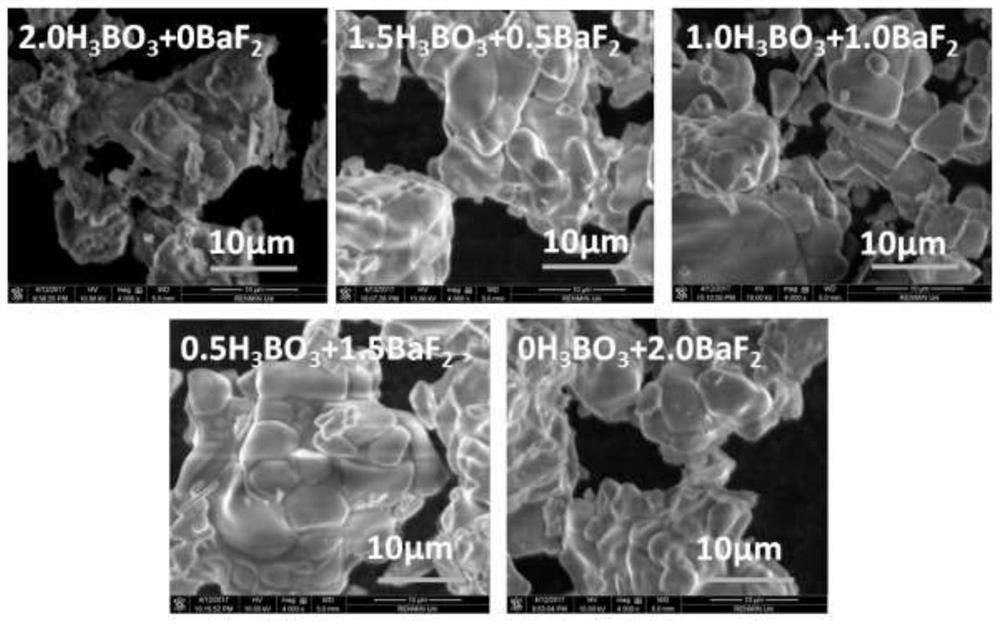

[0025] Example 1. Preparation of high-performance europium and dysprosium co-doped strontium aluminate long-lasting phosphor

[0026] 1) The chemical formula of the europium and dysprosium co-doped strontium aluminate long-lasting phosphor is SrAl 2 o 4 :Eu 2+ , Dy 3+ , weigh the following raw materials in strict accordance with the stoichiometric ratio: SrCO 3 (4.1632g), Al 2 o 3 (3.0588g), Eu 2 o 3 (0.1056g) and Dy 2 o 3 (0.2238g), take by weighing flux 1wt%H simultaneously 3 BO 3 (0.0755g), 1wt% BaF 2 (0.0755g);

[0027] 2) Mix the raw materials weighed in step 1) and place them in a ball mill for ball milling. The speed of the ball mill is 232 rpm, 324 rpm, and milled for 6 hours.

[0028] 3) Transfer the slurry from the ball mill jar to a glass dish with a disposable dropper to obtain a blank; dry the blank at 80°C for 4 hours, and then pour 5% H into the tube furnace 2 and 95%N 2 Mixed weakly reducing gas, sintered at 1300°C for 4h;

[0029] 4) Grinding t...

Embodiment 2

[0030] Example 2. Preparation of high-performance europium and dysprosium co-doped strontium aluminate long-lasting phosphor

[0031] The preparation method is basically the same as in Example 1, the difference is that the flux H in step 1) 3 BO 3 The amount of addition is modified to 0.5wt% (0.0377g), BaF 2 The addition amount of the modified to 1.5wt% (0.1133g).

Embodiment 3

[0032] Example 3. Preparation of high-performance europium and dysprosium co-doped strontium aluminate long-lasting phosphor

[0033] The preparation method is basically the same as in Example 1, the difference is that the flux H in step 1) 3 BO 3 The amount of addition is modified to 1.5wt% (0.1133g), BaF 2 The addition amount of is modified to 0.5wt% (0.0377g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com