Spinning device and process for preparing orderly nanofiber arrays

A technology of nanofiber array and spinning device, which is applied in the direction of melt spinning, textile and papermaking, feeding solution to spinnerets, etc., can solve the problems such as difficult preparation of nanometer ordered microarray fibers, and achieve saving of experimental cost and saving Experimental Space Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

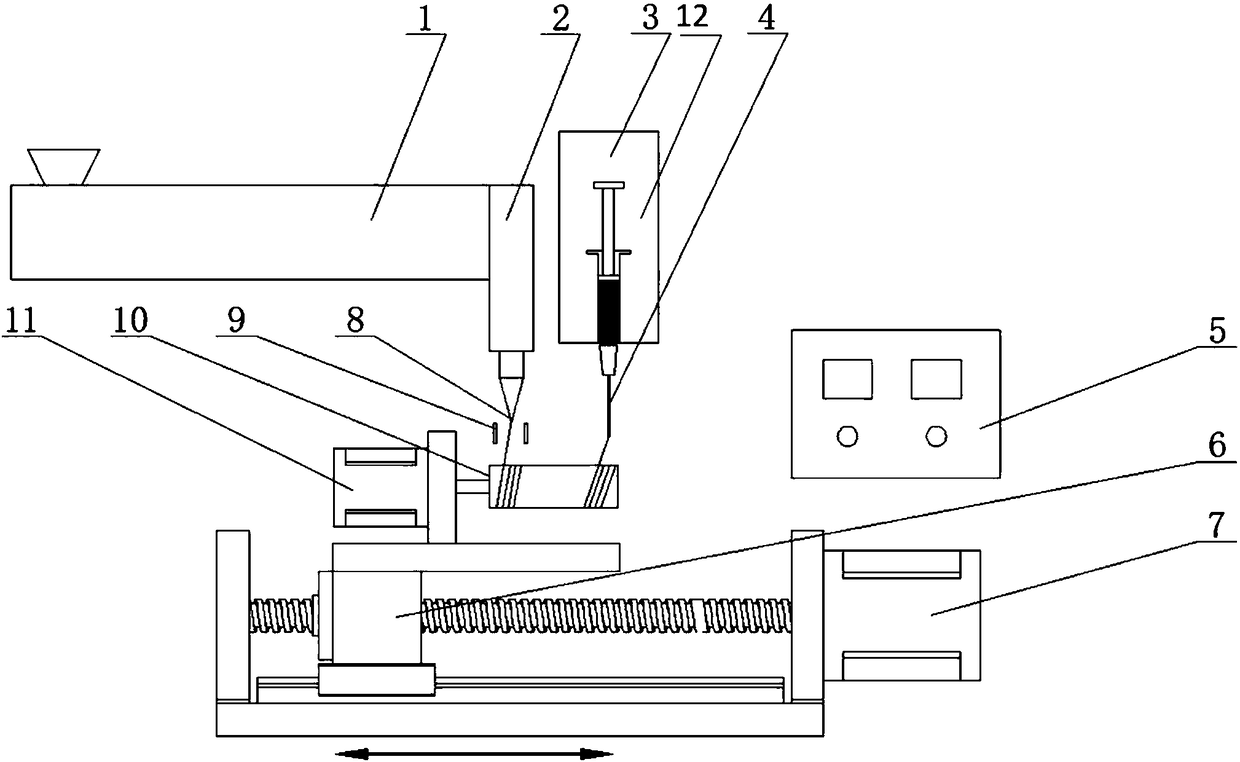

[0025] A multi-functional spinning device, its structural device diagram is as follows figure 1 Shown: consists of melt extruder 1, spinning pump 2, microflow pump 3, needle 4, controller 5, moving platform 6, moving platform motor 7, spinneret 8, curing device 9, receiver 10, receiving The receiver motor 11 and the syringe 12 are composed; the receiver motor 11 is connected with the receiver 10 through a clamping device to drive the receiver 10 to rotate, and a curing device 9 is arranged above the receiver 10 side, directly above the curing device 9 There is a spinneret 8, and the spinneret 8 is welded under the spinning pump 2, and the spinning pump 2 is welded to the melting extruder 1, and there is a needle 4 on the other side of the receiver 10, and the needle 4 is connected to the microflow pump 3. The syringe 12 is welded; the spinning mode is selected through the controller 5 directly above the mobile platform machine 7; the internal circuit of the controller 5 is con...

Embodiment 2

[0027] We adjust the spinning mode by adjusting the controller 5, first adjust the spinning mode to melt spinning, then pour the spinnable polymer particles polylactic acid (PLA) from the melt extruder 1 inlet, and The melting temperature of the polymer is adjusted on the panel to be 170°C, the flow rate of the spinning pump 2 is 0.1ml / h, the speed of the moving platform motor 7 is set at 500μm / s, and the speed of the receiver motor 11 is 500r / s, so that the polymer PLA is heated and melted Become a melt, and the melt will flow through the spinning pump 2 connected to the right side of the melt spinning machine and enter the spinneret 8 below it (the inner and outer diameters of the spinneret are 0.3mm and 0.5mm respectively), forming A thin stream of liquid flows out of the spinning channel and passes through the solidifying device 9 below the spinneret 8 to be solidified into fibers, and the fibers are wound on the receiver below the solidifying device 9 by the action of trac...

Embodiment 3

[0029] We adjust the spinning mode by adjusting the controller 5, first the spinning mode is adjusted to melt spinning, then the spinnable polymer particle polymethyl methacrylate (PMMA) is poured from the melt extruder 1 inlet, and On the panel of the controller 5, the temperature of polymer melting is adjusted to be 120°C and the flow rate of the spinning pump 2 is controlled at 3ml / h, the speed of the moving platform motor 7 is set at 2000 μm / s, and the speed of the receiver motor 11 is 4000r / s, so that the polymerization The material PMMA is heated and melted into a melt, and the melt will flow through the spinning pump 2 connected to the right side of the melt spinning machine and into the spinneret 8 below it (the inner and outer diameters of the spinneret are 0.5mm, 0.7mm, respectively. ), forming a thin stream of liquid, which flows out of the spinning channel and passes through the curing device 9 below the spinneret 8 to be solidified into fibers, and the fibers are w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com