Steam setting device for printing and dyeing cloth

A steam setting and cloth feeding device technology, applied in the field of textile machinery and setting machines, can solve the problems of increasing production costs, polluting the environment, and unequal wrinkles, and achieve the effects of improving the setting effect, reducing pollution, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

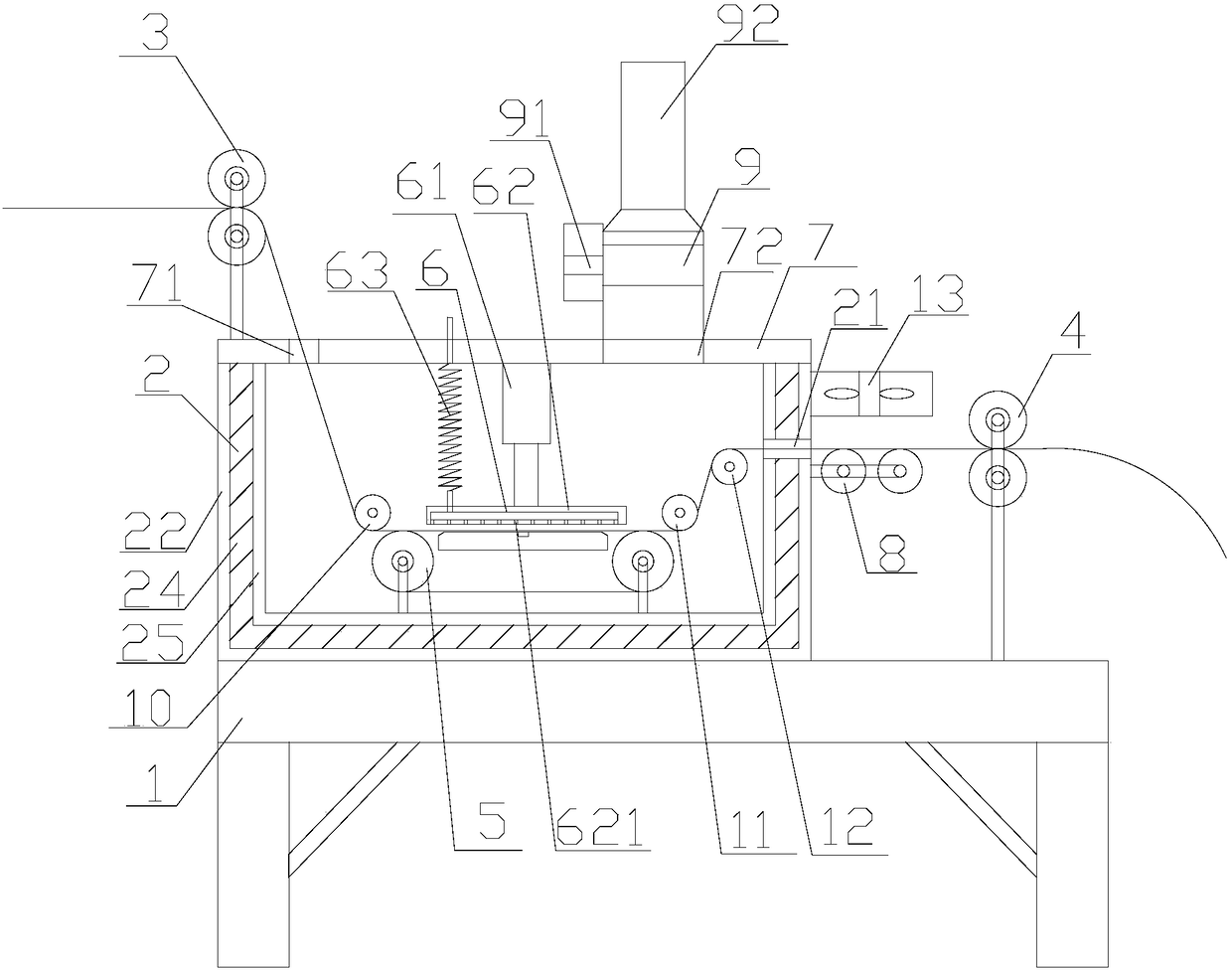

[0015] refer to figure 1 , a printing and dyeing cloth steam setting device of the present invention, comprising a frame 1, a shaping box 2, a cloth feeding device 3, a cloth discharging device 4, a conveyor belt 5, a steam pressing device 6, a case cover 7, a water cooling roller 8, an exhaust Device 9, the first cloth guide roller 10, the second cloth guide roller 11, the third cloth guide roller 12, the frame 1 is provided with a shaping box 2, and the upper end of the shaping box 2 is provided with There is a box cover 7, and the box cover 7 is detachably connected with the stereotyped box body 2. The upper end of the box cover 7 is provided with a cloth feeding device 3, and the box cover 7 is provided with a cloth feeding device 3. Cloth inlet 71, described box cover 7 is provided with air outlet 72, and described air outlet 72 upper end is provided with air exhaust device 9, and described stereotyped casing 2 inner chamber lower end is provided with conveyer belt 5, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com