Air drying program control method and full-automatic washing machine

A fully automatic washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of reducing the automation rate of top-loading fully automatic washing machines, affecting the user's operation time of the whole machine, and shifting the center of gravity of the clothes load, so as to achieve a good air-drying effect and avoid the center of gravity of the clothes. Offset, avoid the effect of center of gravity offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

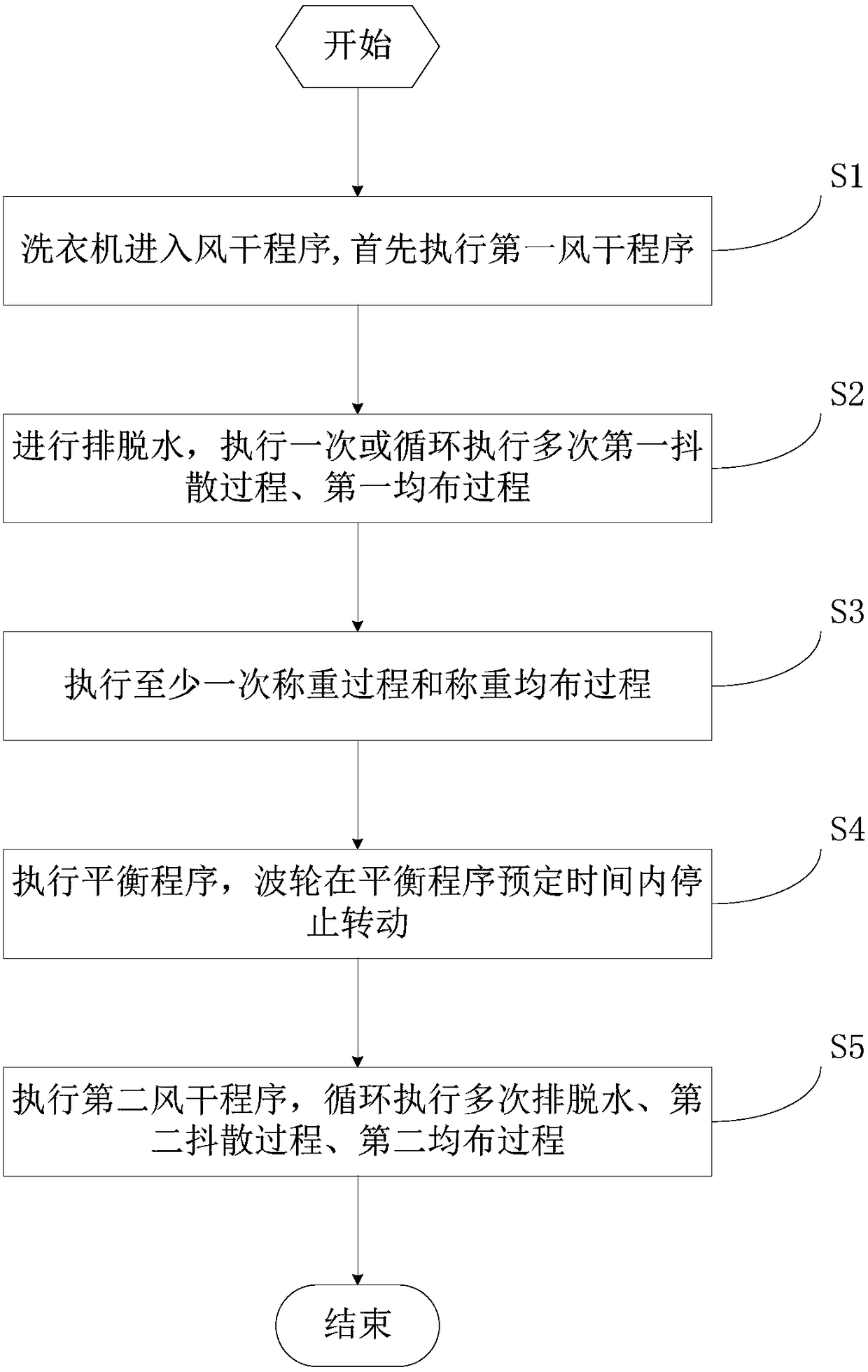

[0039] Such as figure 1 Shown is a schematic flow chart of an air-drying program control method. The air-drying program control method described in this embodiment is applicable to a fully automatic washing machine, specifically a top-loading full-automatic washing machine. After the fully automatic washing machine executes the washing program, rinsing program and dehydration program, it can also choose to execute the air-drying program. In the air-drying program, the pulsator rotates without water to perform water-free washing, and drives the inner tub of the washing machine and the laundry load to rotate to achieve air-drying. The convection generated by the air is mainly used to dry the inner tub and the laundry load, and further relies on the rotation of the inner tub to remove the water attached to the inner tub. Shake dry.

[0040] In the air-drying process control method, a shaking process and a weighing process with different water flow intensities are performed in th...

Embodiment 2

[0053] Not shown in the figure, the difference between this embodiment and the above-mentioned embodiment 1 is that in the first air-drying procedure, the washing machine can execute the supporting first shaking process and the second drying process repeatedly after performing dehydration. 1. Uniform distribution process and supporting weighing process, weighing and uniform distribution process; or the washing machine can perform multiple times of the first shaking process, weighing process, and uniform distribution process after performing dehydration. The process corrects the shift of the center of gravity of the clothes after the first shaking process and the weighing process are completed.

[0054] Alternatively, the three processes can be combined arbitrarily, and multiple cycles can be performed to achieve an air-drying effect similar to that of Embodiment 1.

[0055] Furthermore, the weighing process can actually be regarded as a shaking process for weight detection. In...

Embodiment 3

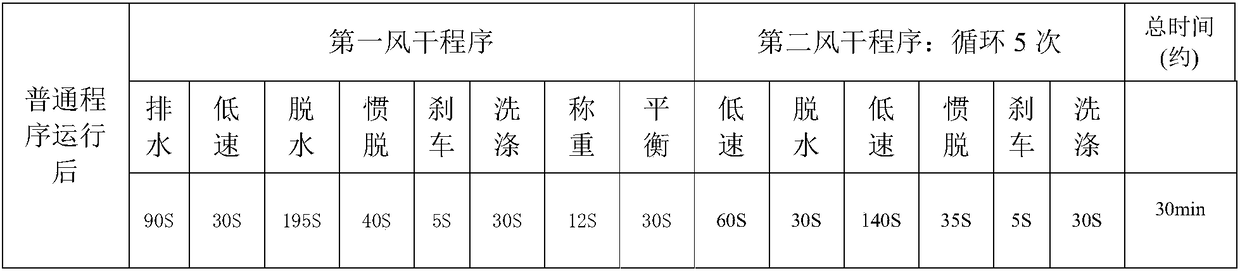

[0057] This embodiment is a further limitation of the first and second embodiments above, as shown in the following table: a time schedule of an air-drying program control method, which provides an overall time design example of an air-drying program.

[0058] Specifically, the total time of the air-drying program in this embodiment is about 30 minutes. The first air-drying program of the air-drying program starts to be executed after the washing machine executes the normal program, or the user can also choose to directly execute the air-drying program. Since the dehydration program uses the rotation of the inner tub to cause centrifugal force to dry the clothes, after the dehydration program is completed, an air-drying process can be designed to further dry the clothes by using the pulsator to rotate.

[0059] When the user chooses to execute the air-drying program, the first air-drying program and the second air-drying program are executed in sequence. Specifically, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com