Gas turbine engine

A gas turbine and engine technology, applied in the direction of gas turbine devices, engine components, machines/engines, etc., can solve the problems of energy waste and insufficient energy utilization, and achieve the effects of sufficient kinetic energy, long action time, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

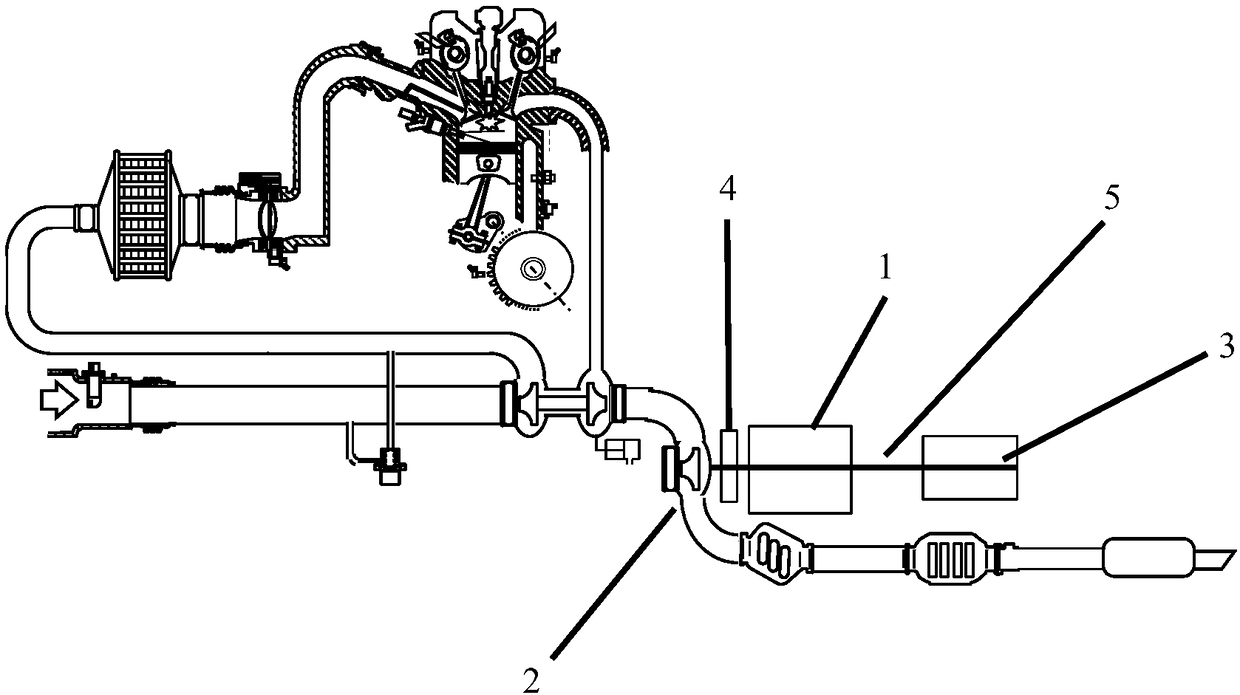

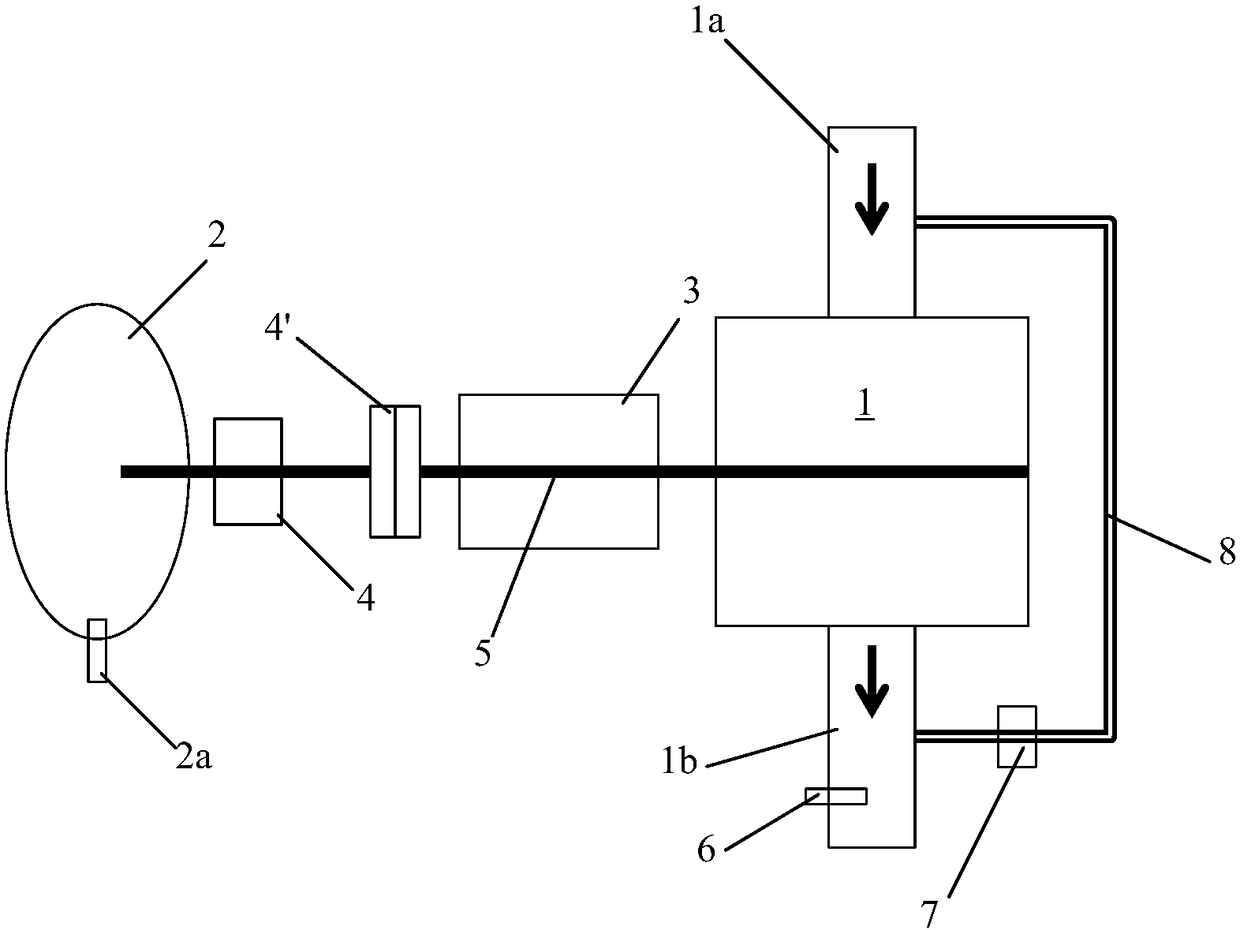

[0054] figure 1 is a structural schematic diagram of a gas turbine engine according to the present invention, and figure 2 Then it shows the first embodiment according to the present invention, in which the connection relationship between the oil pump 1 , the oil pump turbine 2 and the electric machine 3 of the gas turbine engine is briefly shown.

[0055] In the first embodiment of the present invention, the motor 3 is mainly used to drive the oil pump 1 , and the power of the turbine 2 of the oil pump is used as the supplementary power of the motor 3 .

[0056] Specifically, in the gas turbine engine of the first embodiment, the oil pump 1 is associated with the electric machine 3 through the shaft 5, and the electric machine 3 is coaxially connected to the oil pump turbine 2 by means of the reduction gear set 4 and the electromagnetic clutch 4' . A turbine rotational speed sensor 2 a may also be provided to detect the rotational speed of the oil pump turbine 2 . At this...

no. 2 example

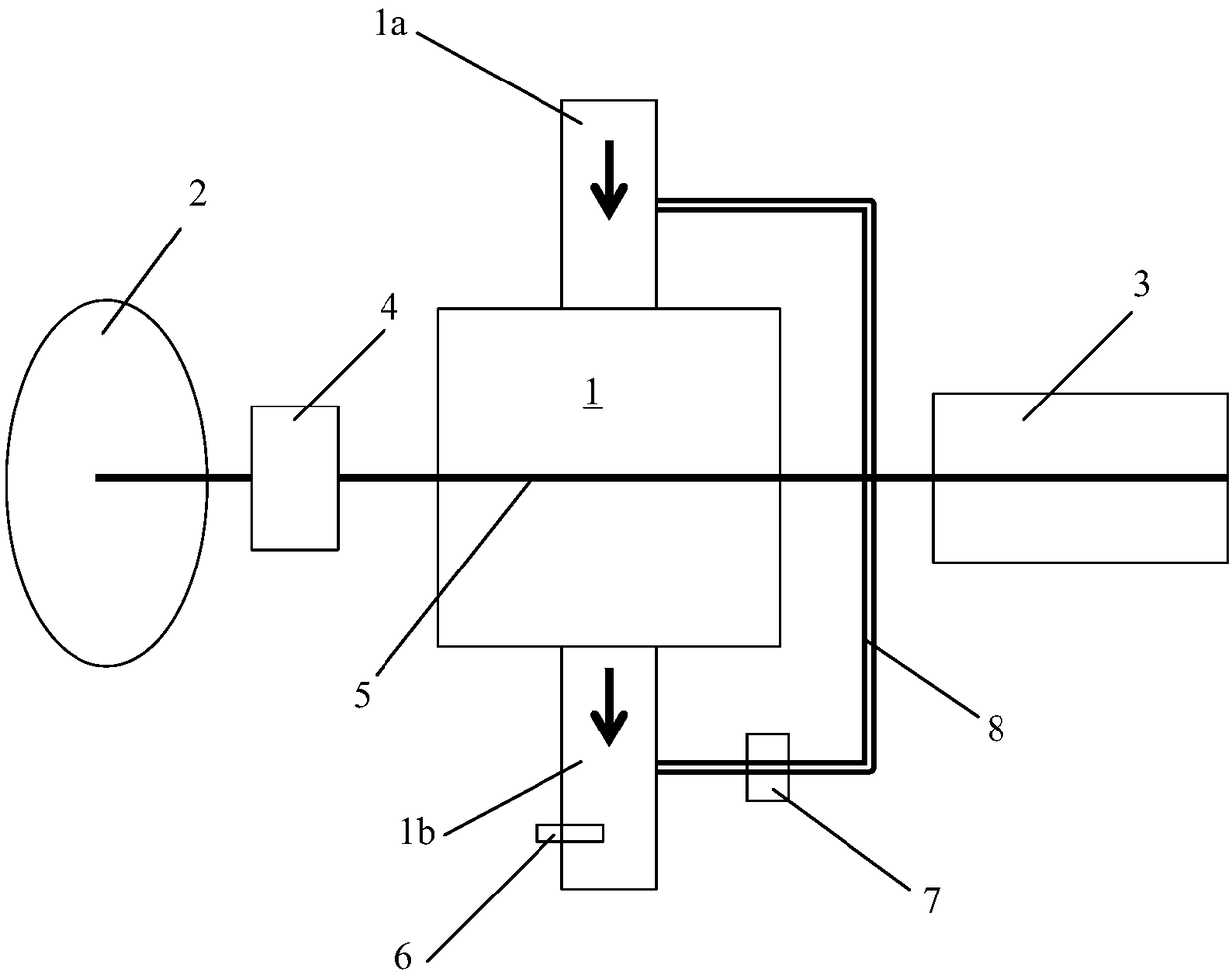

[0063] image 3 A second embodiment according to the present invention is shown, in which the connection relationship between the oil pump 1 , the oil pump turbine 2 and the electric machine 3 of the gas turbine engine is briefly shown.

[0064] In the second embodiment of the present invention, the power of the oil pump turbine 2 is mainly used to drive the oil pump 1, and the power of the motor 3 is used as supplementary power, and the remaining kinetic energy is used to drive the motor 3 to generate electricity.

[0065] Specifically, in the gas turbine engine of the second embodiment, the oil pump 1 is associated on the one hand with the electric machine 3 via the shaft 5 and is coaxially connected to the oil pump turbine 2 with the reduction gear set 4 on the other hand. At this time, different from the first embodiment, the motor 3 and the oil pump turbine 2 are located on both sides of the oil pump 1 , and work on the oil pump 1 through the shaft 5 .

[0066] The oil p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap