Lubricating method of water lubricated bearing based on micro oil droplet lubrication start and stop protection

A water-lubricated bearing and sliding bearing technology, used in the lubrication of engines, rigid supports of bearing components, shafts and bearings, etc., can solve the problems of bearing wear, affecting bearing life and performance, bearing material wear, etc. Ingenious design, good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

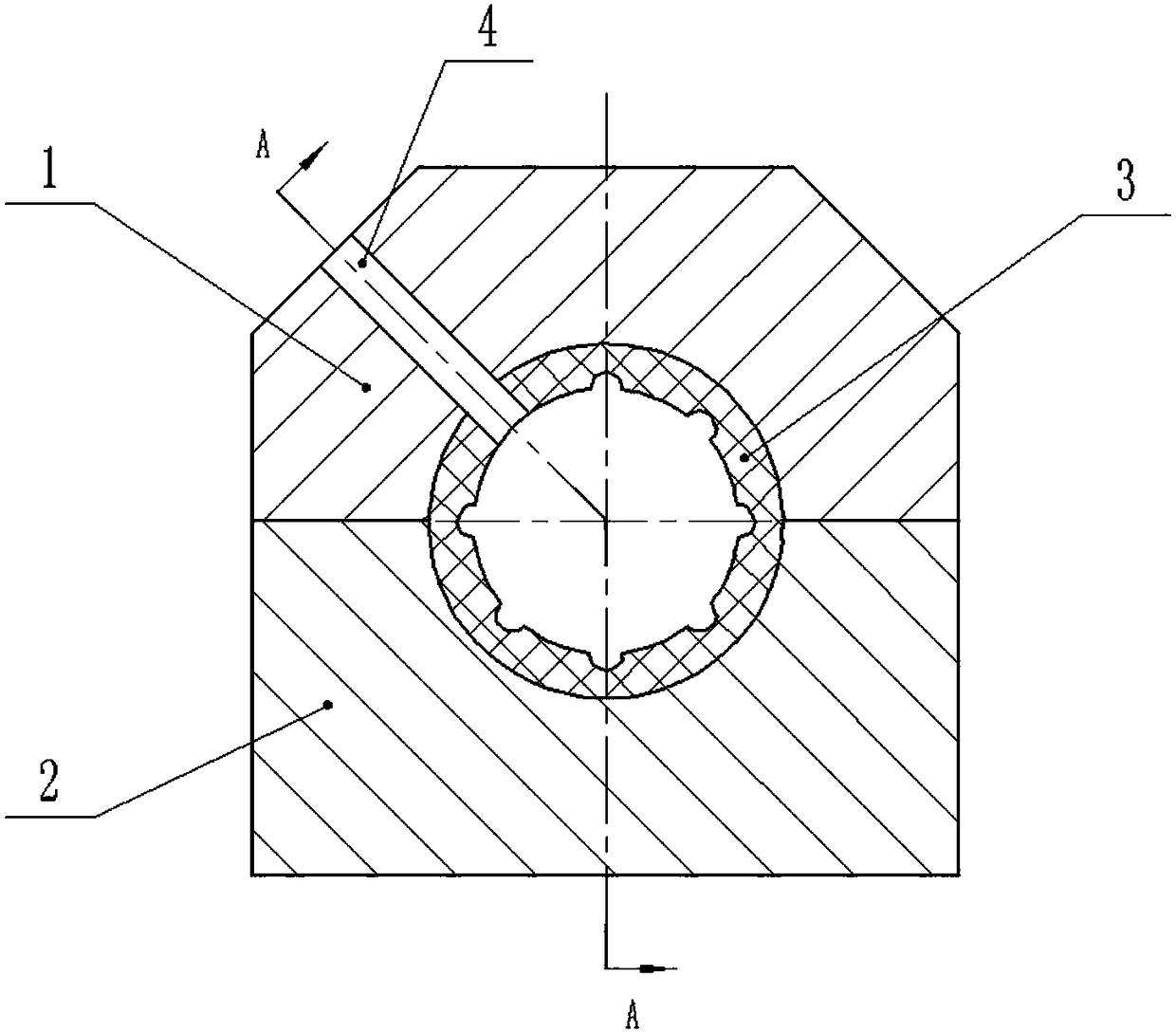

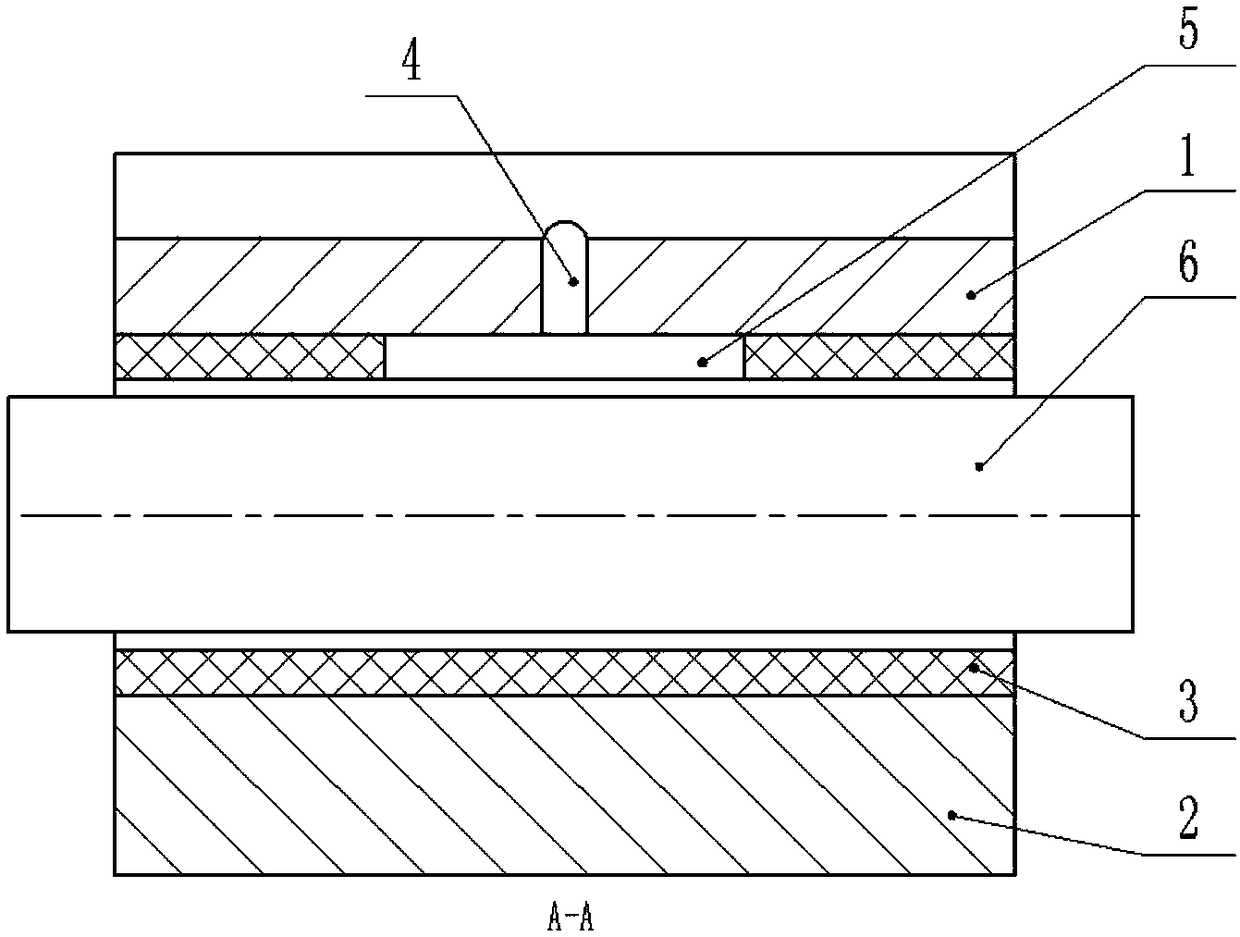

[0020] In this embodiment, the lubrication method of the water-lubricated bearing based on the start-stop protection of micro-oil droplet lubrication is realized based on the oil-water mixed lubrication sliding bearing. The main structure of the oil-water mixed lubrication sliding bearing includes: the upper bearing seat 1 , lower bearing seat 2, bushing 3, oil injection hole 4, oil groove 5, rotating shaft 6; a hollow cylindrical bushing 3 is arranged in the middle of the upper bearing seat 1 and the lower bearing seat 2, and the outer edge of the bushing 3 is evenly distributed There is an oil tank for storing lubricant. The rotating shaft 6 is installed in the bushing 3. The rotating shaft 6 can rotate relative to the bushing 3. There is an oil filling hole 4 on the upper left side of the upper bearing seat 1. The oil filling hole 4 is a cylindrical structure extending obliquely , the upper end of the oil injection hole 4 is connected to the lubricant supply system for deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com