Ultra-high temperature mechanical and thermal coupling strain gauge and working method based on reflection x-ray in-situ experiment

An X-ray and reflective technology, applied in the field of high-temperature mechanical-thermal coupling strain gauges, can solve the problems of lack of test benches, difficulty in tracking observation positions, and deficiencies, and achieve the effect of reducing mechanical drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the drawings and specific embodiments.

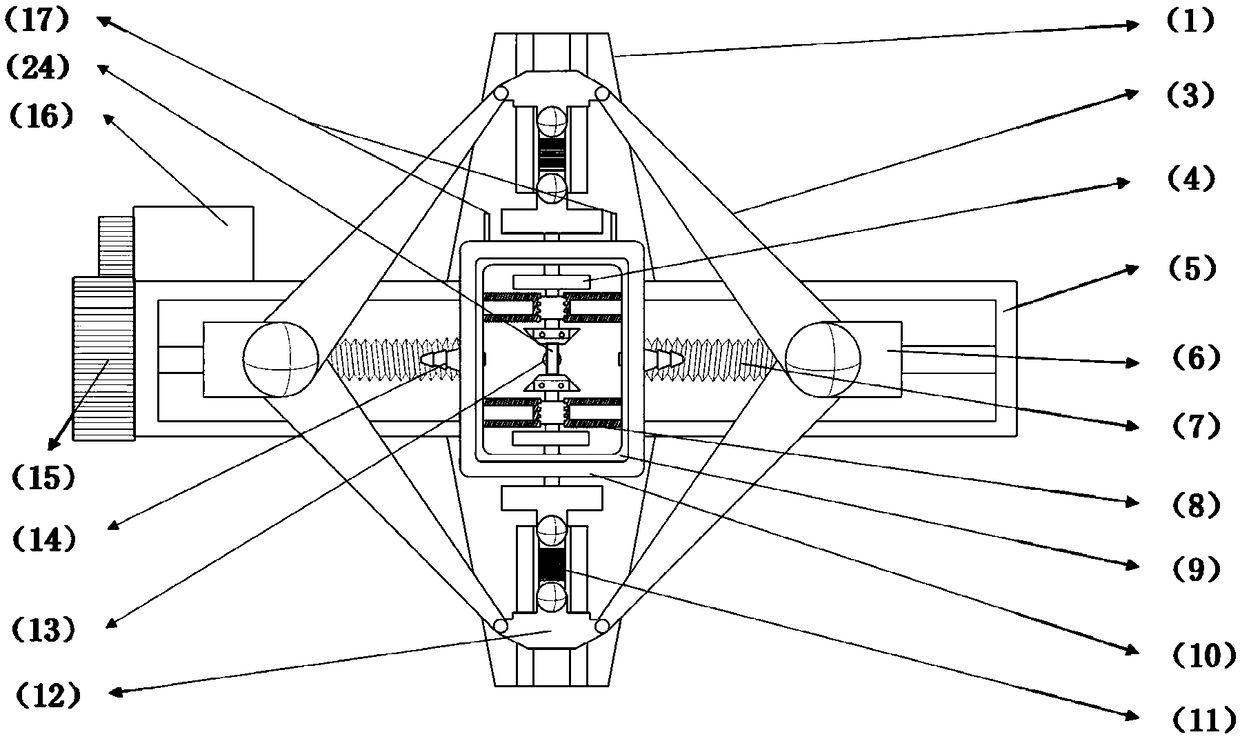

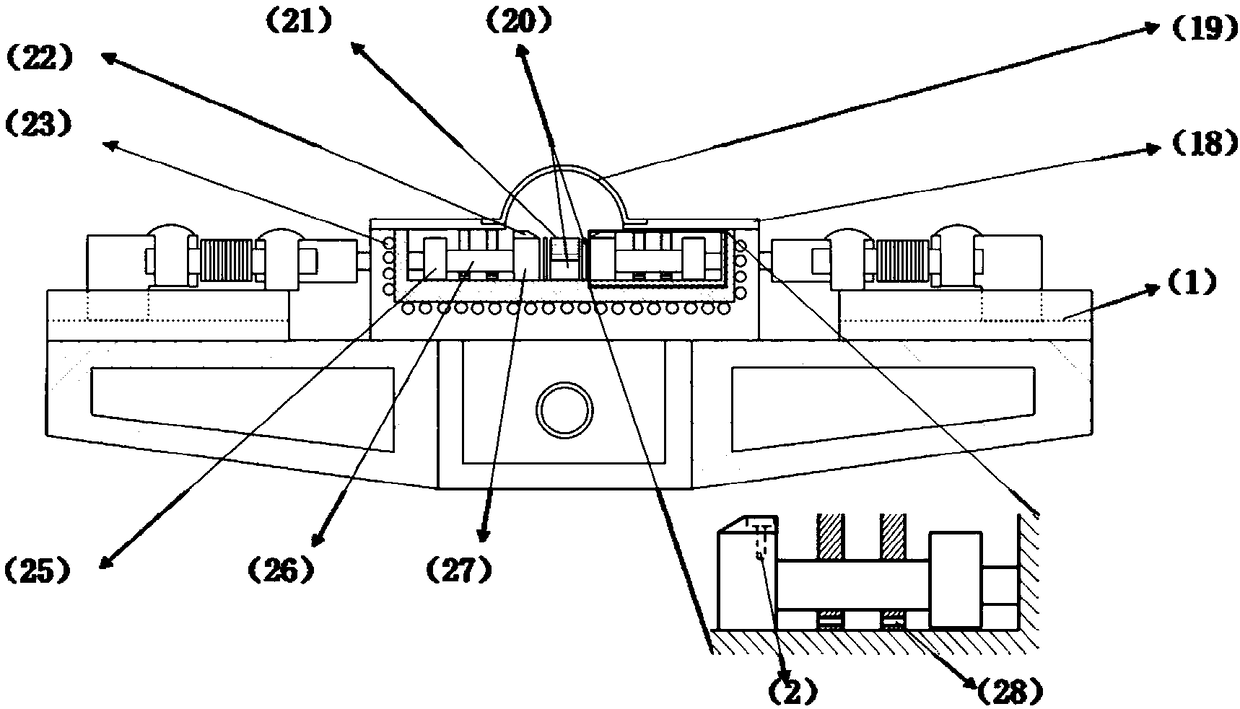

[0026] like figure 1 and figure 2As shown, the present invention is based on a reflective X-ray in-situ experiment ultra-high temperature mechanical-thermal coupling strain gauge, including a base 5, a bidirectional screw 7 installed in the base 5 parallel to the long side of the base, the bidirectional screw 7 is driven by a motor 16 and a transmission group 15 transmission to realize movement, with the help of the two-way screw 7 to realize the moving block 6 that moves in the opposite direction, the moving block 6 is set on both sides of the two-way screw 7 and placed oppositely; four connecting rods 3 are connected in pairs to form a quadrilateral structure, and two diagonal nodes are connected to move Block 6, a pair of sliders 12 are installed on the other two diagonal nodes of the unconnected moving block 6 and placed on the slide rail 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com