A two-photon fluorescence enhancement method and its application

A two-photon fluorescence and fluorescent material technology, applied in the field of optoelectronics, can solve the problems of unfavorable optical signal transmission and utilization, unfavorable low-cost micro-nano composite structure, complex process, etc., and achieve the effect of low cost, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

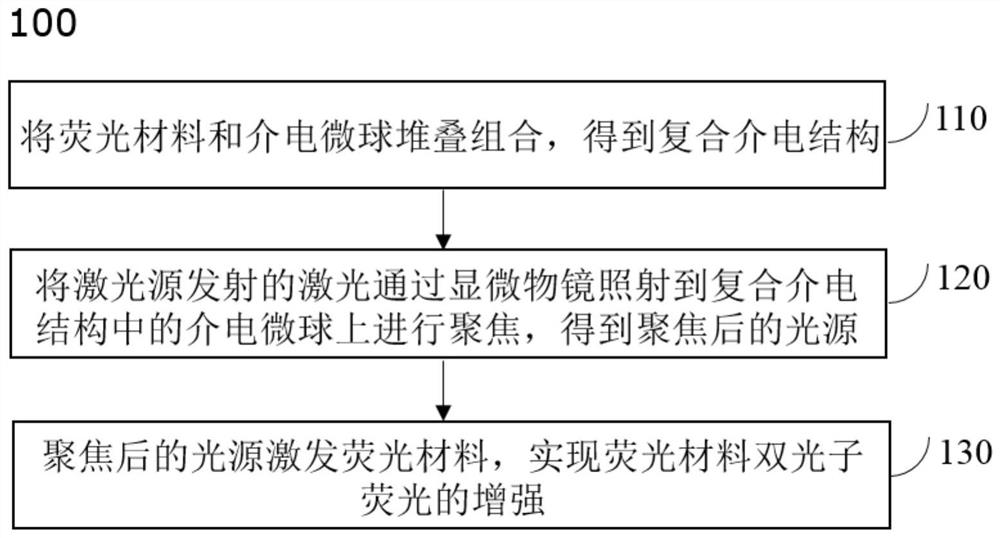

[0048] A method 100 for enhancing two-photon fluorescence, such as figure 1 shown, including:

[0049] Step 110, stacking and combining the fluorescent material and the dielectric microspheres to obtain a composite dielectric structure.

[0050] Step 120 , irradiating the laser light emitted by the laser source onto the dielectric microspheres in the composite dielectric structure through a microscope objective lens for focusing to obtain a focused light source.

[0051] Step 130, the focused light source excites the fluorescent material to realize enhancement of two-photon fluorescence of the fluorescent material.

[0052] Due to the photon jet effect of the dielectric microspheres, the light beam can be focused on the sub-wavelength scale, so that the light intensity in the focused area is greatly increased. For two-photon fluorescence, the fluorescence intensity is proportional to the square of the excitation light intensity. If a dielectric microsphere is used to focus the...

Embodiment 2

[0055] On the basis of Embodiment 1, in the composite dielectric structure, the dielectric microspheres are a single dielectric microsphere or an array of dielectric microspheres.

[0056] A single microsphere or a microsphere array can greatly enhance the two-photon fluorescence intensity of the fluorescent material, so it has a wide range of applications and can be used according to actual conditions, which is convenient and quick. Among them, a single dielectric microsphere or a dielectric microsphere array can be prepared by the following method: take a small amount of suspension of dielectric microspheres and drop them on a clean quartz substrate and place them in an oven with a temperature of 70°C. Under the action of liquid tension, the dielectric microspheres form a single-layer dense microsphere array or dispersed single dielectric microspheres by self-assembly, and keep them in the oven for about 10 minutes to dry them completely. A single dielectric microsphere or a...

Embodiment 3

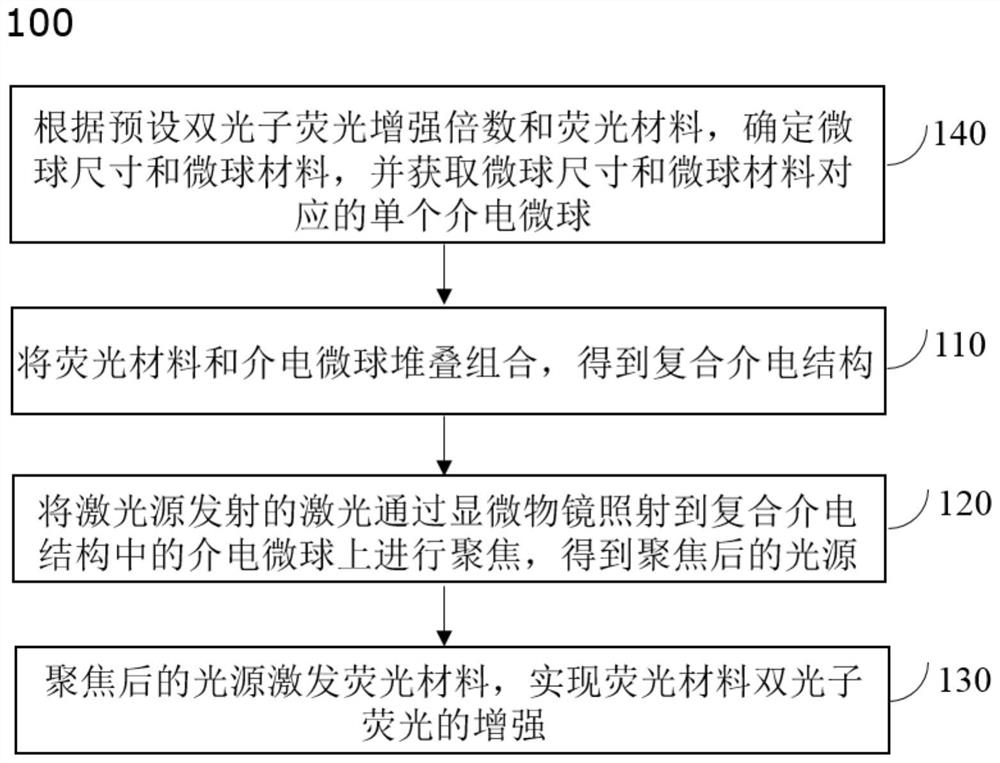

[0058] On the basis of embodiment one or embodiment two, when the dielectric microsphere is a single dielectric microsphere, such as figure 2 As shown, before step 110, method 100 also includes:

[0059] Step 140: Determine the microsphere size and microsphere material according to the preset two-photon fluorescence enhancement factor and fluorescent material, and obtain a single dielectric microsphere corresponding to the microsphere size and microsphere material;

[0060] or,

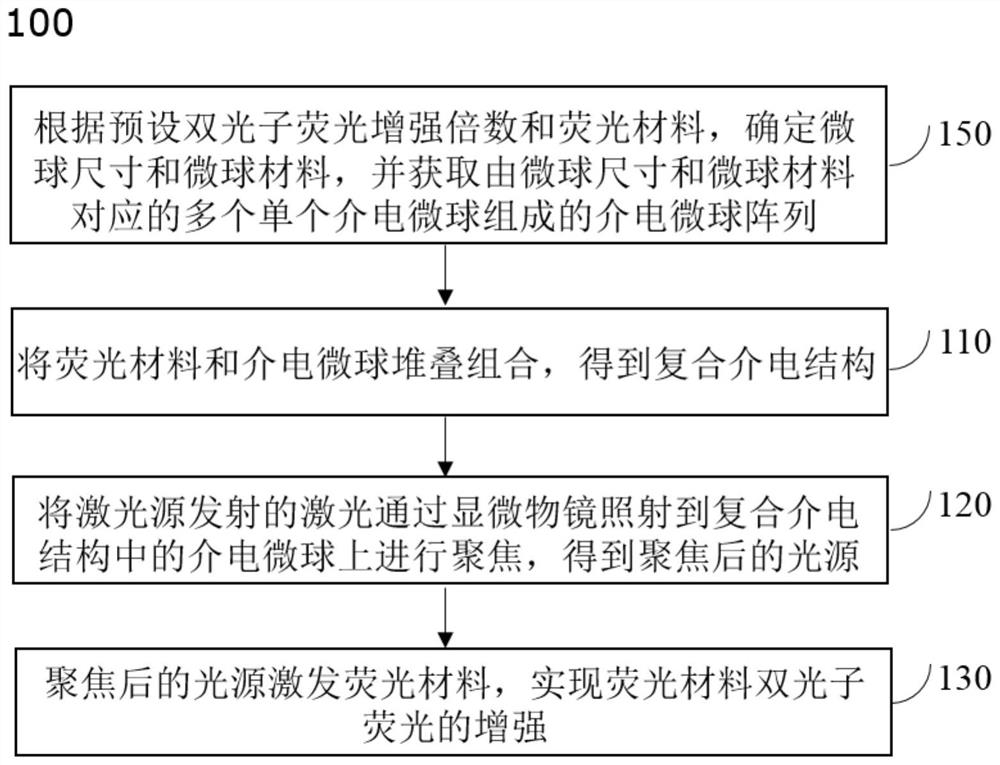

[0061] When the dielectric microsphere is a dielectric microsphere array, such as image 3 As shown, before the step 110, the method 100 also includes:

[0062] Step 150: Determine the microsphere size and microsphere material according to the preset two-photon fluorescence enhancement factor and fluorescent material, and obtain a dielectric microsphere array composed of a plurality of single dielectric microspheres corresponding to the microsphere size and microsphere material .

[0063] Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com