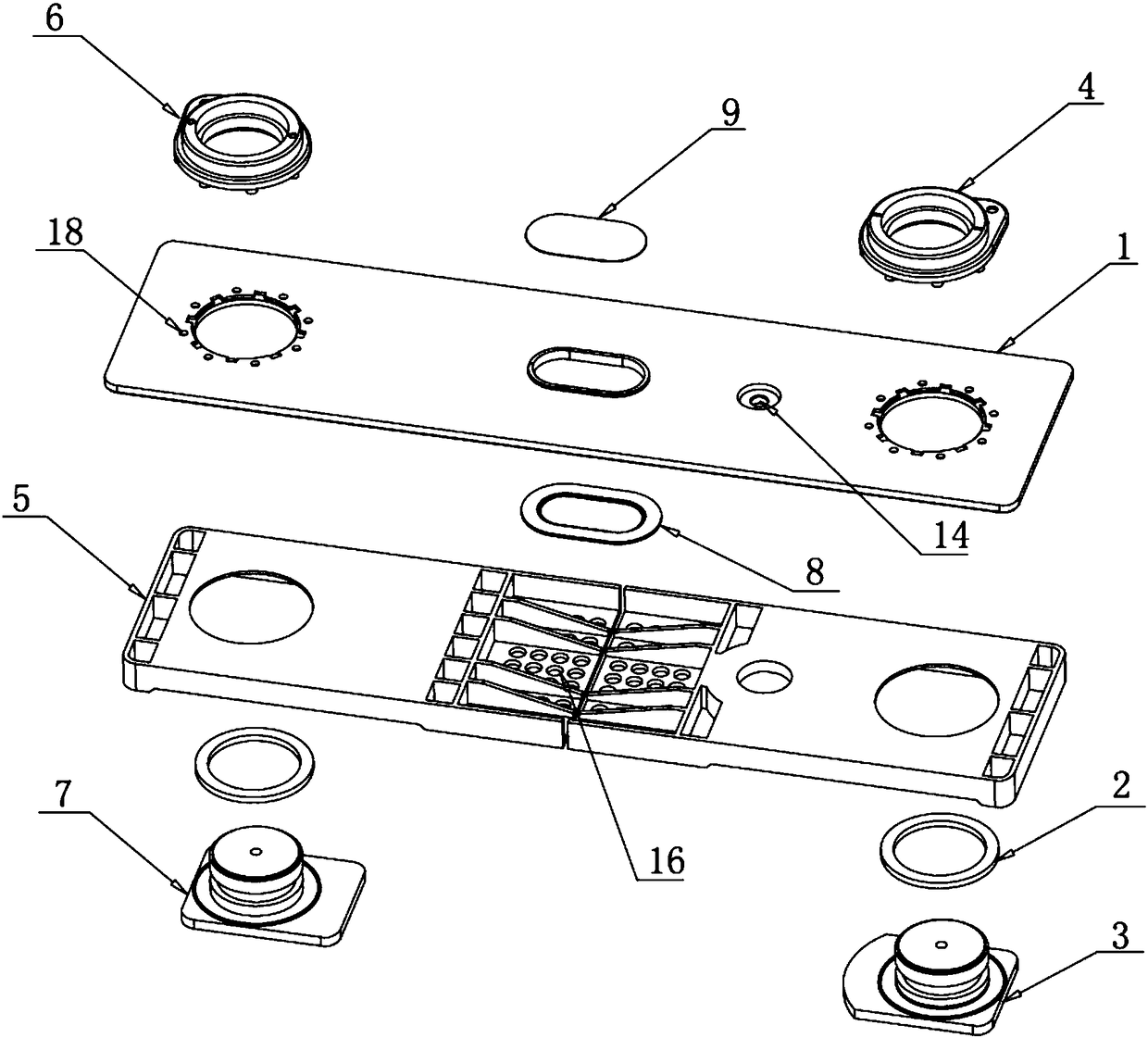

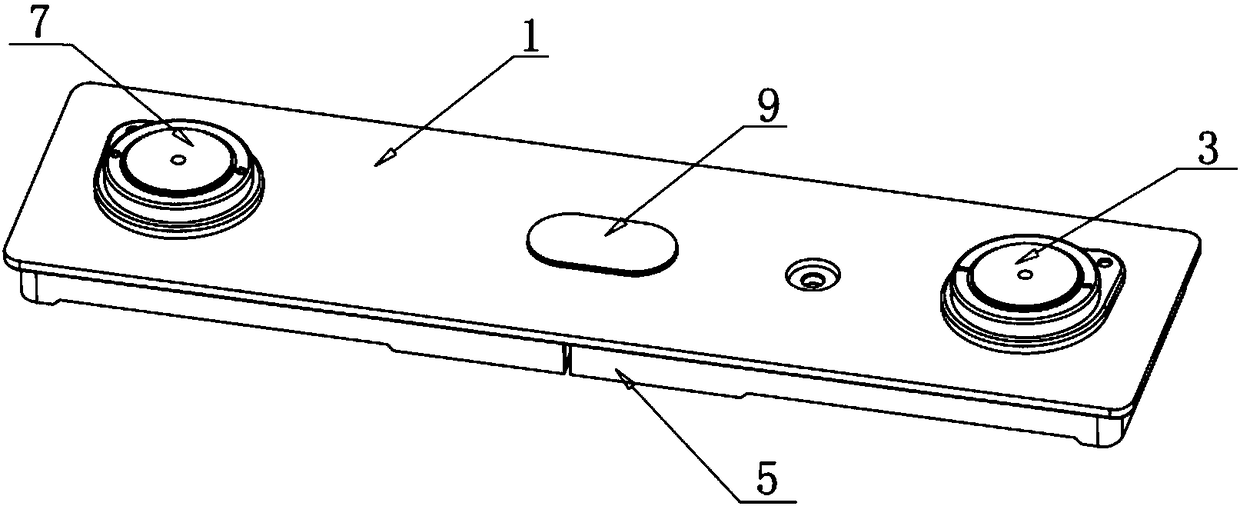

Power battery top cover based on tab direct-leading type flat welding structure

A direct ear type, power battery technology, applied in the direction of battery cover/end cover, structural parts, battery pack parts, etc., can solve the problems of reducing product qualification rate, reduce defective products, shorten distance, and improve market competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] According to the solution of the present invention, three samples of the top cover of the power battery with different heights of the upper plastic 5 were produced and connected with the bare battery using the tab direct-lead flat welding structure, and then the above-mentioned samples were compared with the battery using the traditional support frame (Other influencing factors are exactly the same).

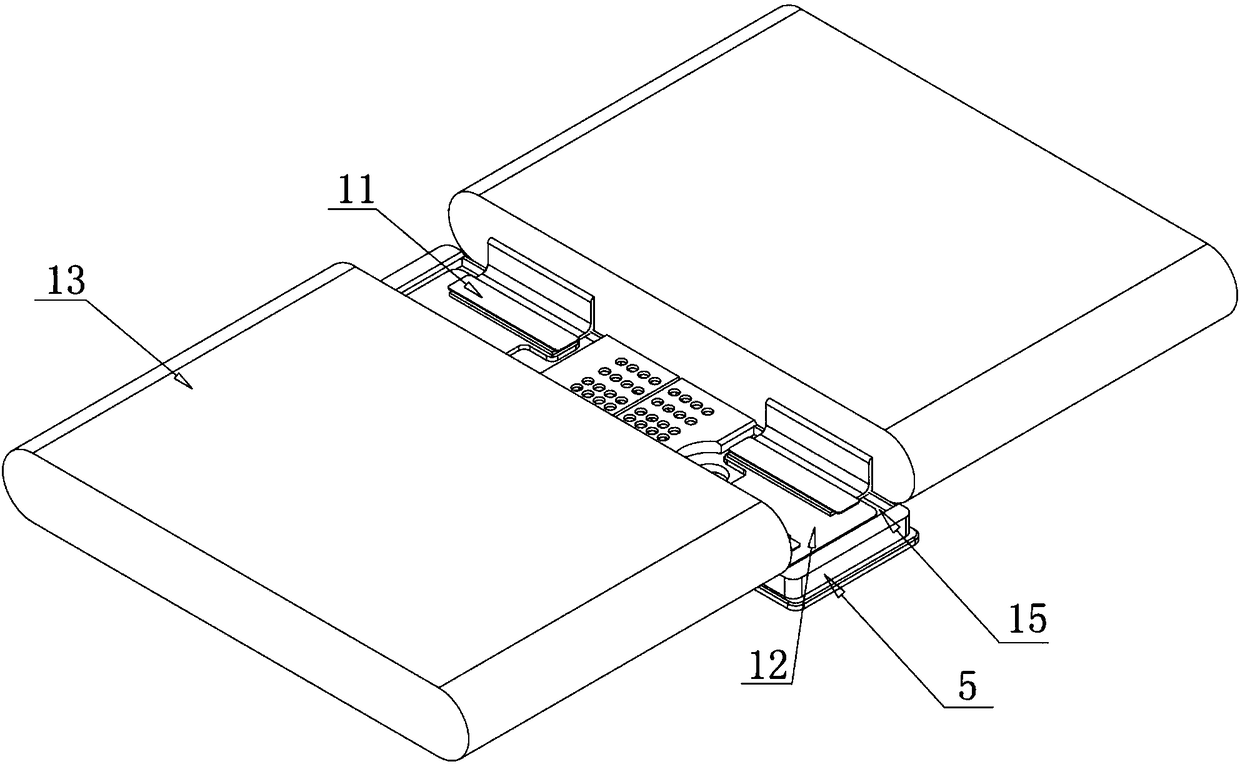

[0041] Among them, the upper plastic 5 of the power battery top cover sample is made of PP HJ400 material, the upper cover plate 1 is made of AL3003-H14 material, the positive pole 7 is made of AL3003-H16 material, and the negative pole 3 is made of Cu T2+AL1060- Made of H12 alloy material. In the sample, the metal shield 11 connected to the positive pole 7 is made of AL 1060 material, the metal shield 11 connected to the negative pole 3 is made of T2 copper, and the metal hard connector 12 connected to the positive pole 7 is made of AL 1060O The metal hard connector 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com