Direct torque control method for a three-phase four-switch permanent magnet synchronous motor speed control system

A technology of permanent magnet synchronous motor and direct torque control, which is applied in motor control, motor generator control, AC motor control, etc. It can solve the problems of limited control accuracy, large fluctuations in torque and flux linkage, and affecting motor performance, etc. problems, to achieve the effect of improving running performance and precise torque control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

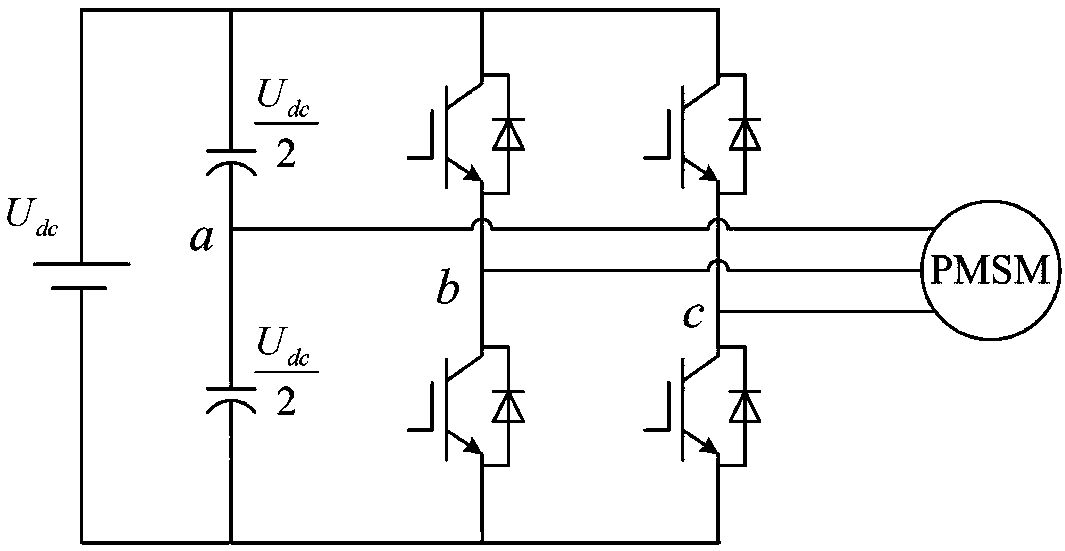

[0033] figure 1 It is a structural diagram of the power main circuit of the three-phase four-switch inverter driving the permanent magnet synchronous motor speed control system implemented in the patent of the present invention. Such as figure 1 As shown, phase B and phase C of the motor are connected to the two-phase normal bridge arms of the inverter, and phase A is connected to the neutral point of the DC capacitor.

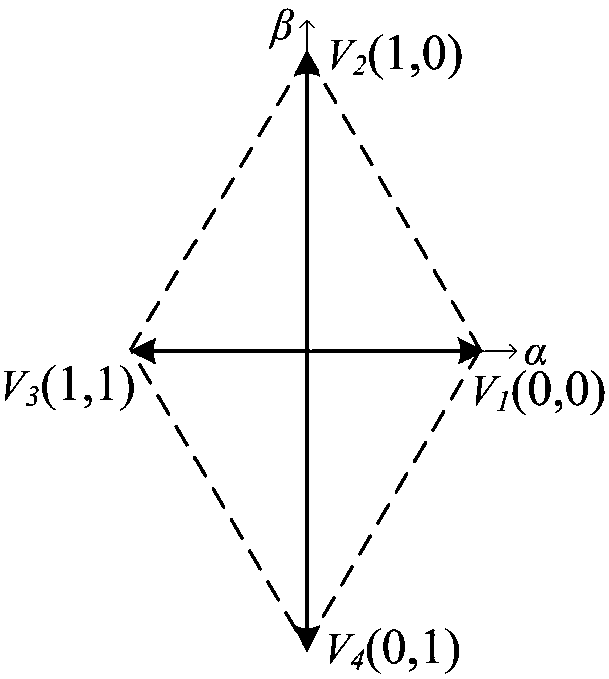

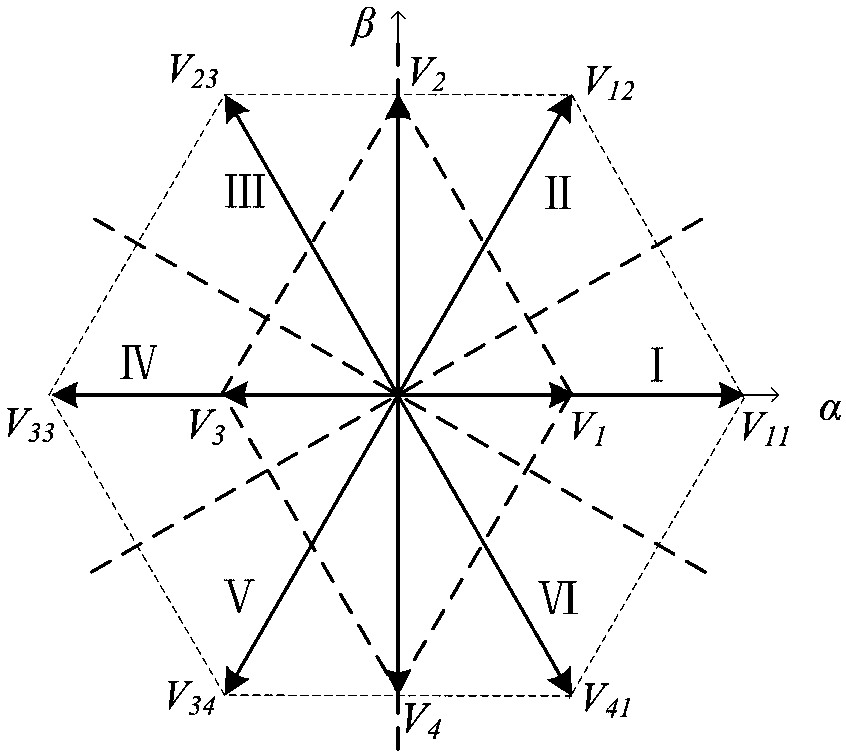

[0034] with S x (x=B, C) represents the switching state of the power switch tube on the two-phase bridge arms of B and C, S x =1 when the upper tube of the bridge arm is on and the lower tube is off, S x =0, when the lower tube of the bridge arm is turned on, the upper tube is turned off. The four switching tubes on the two-phase bridge arm have four switching states, and four basic voltage vectors V 1 , V 2 , V 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com