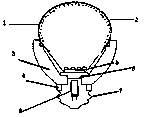

Near ultraviolet LED mosquito repelling lamp and manufacturing method thereof

A near-ultraviolet, mosquito repellent lamp technology, applied in chemical instruments and methods, animal repellents, luminescent materials, etc., can solve the problems of polluting the environment, excessive blue light, affecting human health, etc., to save energy, reduce pollution, avoid Effects of photobiohazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

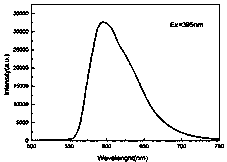

[0017] A. Preparation of phosphor powder: weigh Ca(NO 3 ) 2 .4H 2 O 12.6340g, Ti(OC 4 h 9 ) 4 17.018g, Si(OC 2 h 5 ) 4 4.1666g, MnCO 3 0.6897g, Eu 2 o 3 0.088g, Ca(NO 3 ) 2 .4H 2 O dissolved in deionized water, the MnCO 3 、Eu 2 o 3 Put it into a 100ml beaker, mix well, add deionized water to make the mixture a uniform paste, add concentrated nitric acid dropwise to dissolve the paste completely, then add Ca(NO 3 ) 2 .4H 2 O solution, take another 100ml beaker, add Ti(OC 4 h 9 ) 4 , Si(OC 2 h 5 ) 4 , add absolute ethanol to dissolve it completely, then mix the solution with the aforementioned mixed solution to obtain a precursor solution, leave the precursor solution for 4 hours, put it in an oven at 80°C to concentrate and process it into a transparent gel, and then Put it into a crucible and heat it at 230°C for 4 hours, and sieve it after cooling to obtain a precursor. In the precursor, add 1g H 3 BO 3 , 1g CaF 2 , after mixing evenly, put it ...

Embodiment 2

[0021] A. Preparation of phosphor powder: weigh Ca(NO 3 ) 2 .4H 2 O 6.7303g, Ti(OC 4 h 9 ) 4 6.8072g, Si(OC 2 h 5 ) 4 4.1666g, MnCO 3 0.1150g , Eu 2 o 3 0.0704g, Ca(NO 3 ) 2 .4H 2 O dissolved in deionized water, the MnCO 3 、Eu 2 o 3 Put it into a 100ml beaker, mix well, add deionized water to make the mixture a uniform paste, add concentrated nitric acid dropwise to dissolve the paste completely, then add Ca(NO 3 ) 2 .4H 2 O solution, take another 100ml beaker, add Ti(OC 4 h 9 ) 4 , Si(OC 2 h 5 ) 4 , add absolute ethanol to dissolve it completely, then mix the solution with the aforementioned mixed solution to obtain a precursor solution, leave the precursor solution for 4 hours, put it in an oven at 65°C to concentrate and process it into a transparent gel, and then Put it into a crucible and heat it at 215°C for 4 hours, and sieve it after cooling to obtain a precursor. In the precursor, add 0.4g H 3 BO 3 , 0.2 g SrF 2 , after mixing evenly, ...

Embodiment 3

[0025] A. Preparation of phosphor powder: weigh Ca(CO 3 ) 2 5.8552g, Ti(OC 4 h 9 ) 4 17.018g, Si(OC 2 h 5 ) 4 4.1666g, MnCO 3 0.0575g, Eu 2 o 3 0.1760g, Ca(CO 3 ) 2 , MnCO 3 、Eu 2 o 3 Put it into a 100ml beaker, mix well, add deionized water to make the mixture a uniform paste, add concentrated nitric acid dropwise to dissolve the paste completely, take another 100ml beaker, add Ti(OC 4 h 9 ) 4 , Si(OC 2 h 5 ) 4 , add absolute ethanol to dissolve it completely, then mix this solution with the aforementioned mixed solution to obtain a precursor solution, leave the precursor solution for 4 hours, put it in an oven at 75°C to concentrate and process it into a transparent gel, and then Put it into a crucible and heat it at 225°C for 3.5h, and sieve it after cooling to obtain a precursor. In the precursor, add 0.4g H 3 BO 3 , 1.6g BaF 2 , after mixing evenly, put it into a high-temperature burning electric furnace, roast at 1200 ° C for 5 hours, cool to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com