A kind of compound cake emulsion and preparation method thereof

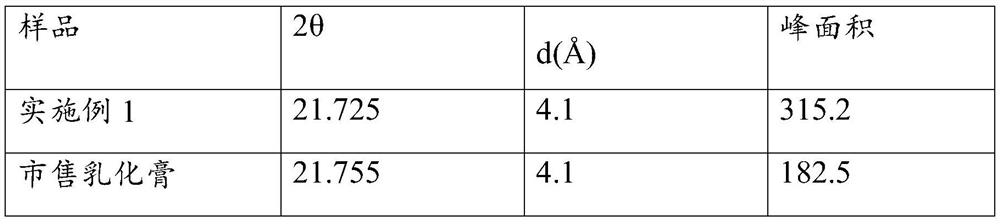

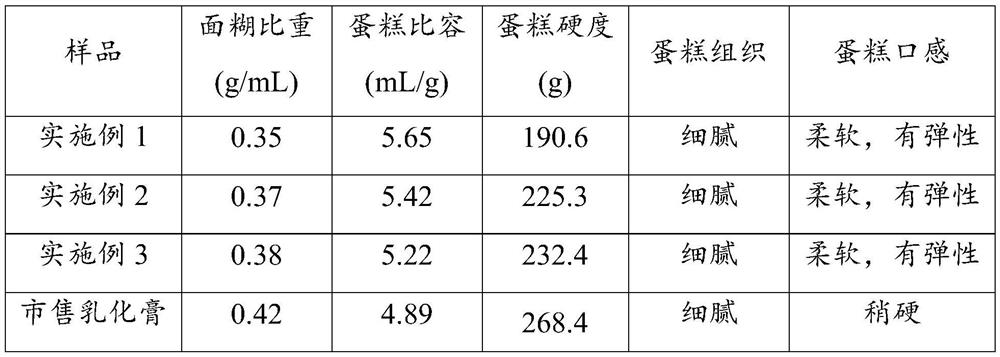

A technology for emulsifying cream and cake, which is applied in baking, food science, application, etc. It can solve the problem of insufficient anti-aging performance, poor quality of cake emulsifying cream, and insufficient stability of mono- and diglyceride fatty acid ester α-crystal forms, etc. problems, achieve better taste, improve nutrition and health, and improve competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] As an embodiment of the compound cake emulsifying cream described in the present invention, the compound cake emulsifying cream described in this embodiment comprises the following components in parts by weight:

[0036] Mono- and Diglycerides of Fatty Acids 15%

[0037] Propylene Glycol 8%

[0038] Propylene glycol fatty acid ester 7%

[0039] Phospholipids 5%

[0040] Soybean polysaccharide 6%

[0041] Sorbitol Liquid 22%

[0042] Deionized water 37%

[0043] Wherein, the mass fraction of sorbitol in the sorbitol liquid is 70%.

[0044] The preparation method of compound cake emulsifying paste described in the present embodiment is:

[0045] (1) Industrial production water is purified by a deionization machine to obtain deionized water (conductivity ≤ 40μs / cm), which is pumped into the water phase pot;

[0046] (2) After the water phase pot is heated up to 75°C, the sorbitol liquid and propylene glycol are pumped in, stirred and mixed evenly to form a water phase...

Embodiment 2

[0051] As an embodiment of the compound cake emulsifying cream described in the present invention, the compound cake emulsifying cream described in this embodiment comprises the following components in parts by weight:

[0052] Mono- and Diglycerides of Fatty Acids 11%

[0053] Propylene Glycol 10%

[0054] Propylene glycol fatty acid ester 7%

[0055] Phospholipids 3%

[0056] Soy Polysaccharide 4%

[0057] Sorbitol Liquid 25%

[0058] Deionized water 40%

[0059] Wherein, the mass fraction of sorbitol in the sorbitol liquid is 70%.

[0060] The preparation method of compound cake emulsifying paste described in the present embodiment is:

[0061] (1) Industrial production water is purified by a deionization machine to obtain deionized water (conductivity ≤ 40μs / cm), which is pumped into the water phase pot;

[0062] (2) Add sorbitol liquid and propylene glycol into deionized water, heat to 70°C, stir and mix evenly to obtain water phase material;

[0063] (3) melting ...

Embodiment 3

[0067] As an embodiment of the compound cake emulsifying cream described in the present invention, the compound cake emulsifying cream described in this embodiment comprises the following components in parts by weight:

[0068] Mono- and Diglycerides of Fatty Acids 12%

[0069] Propylene Glycol 9%

[0070] Propylene glycol fatty acid ester 8%

[0071] Phospholipids 2%

[0072] Soy Polysaccharide 4%

[0073] Sorbitol Liquid 25%

[0074] Deionized water 40%

[0075] Wherein, the mass fraction of sorbitol in the sorbitol liquid is 70%.

[0076] The preparation method of compound cake emulsifying paste described in the present embodiment is:

[0077] (1) Industrial production water is purified by a deionization machine to obtain deionized water (conductivity ≤ 40μs / cm), which is pumped into the water phase pot;

[0078] (2) Add sorbitol liquid and propylene glycol into deionized water, heat to 72°C, stir and mix evenly to obtain water phase material;

[0079] (3) melting m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com