Power battery heat management system and method for electric vehicle

A thermal management system and power battery technology, applied in electric vehicles, batteries, secondary batteries, etc., can solve the problems of poor cooling effect, poor heat dissipation effect, obvious cooling effect, etc., and achieve the effect of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

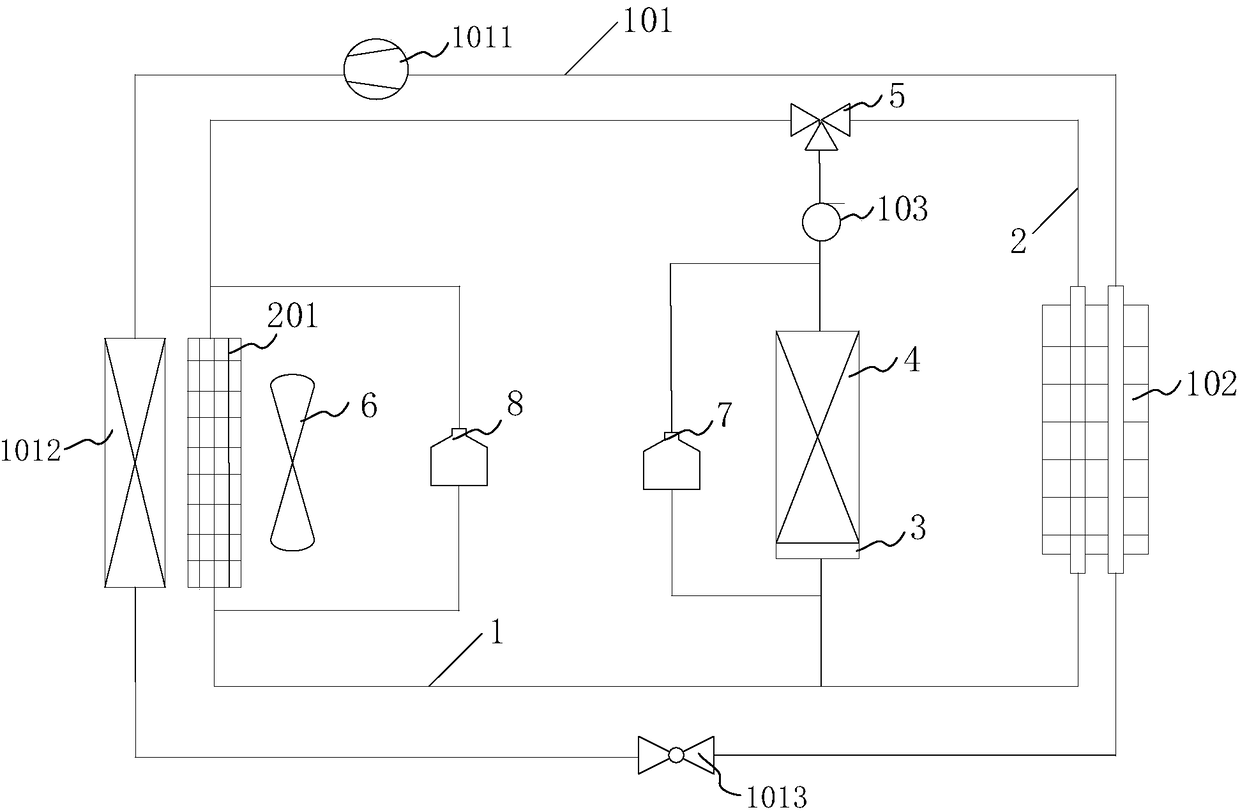

[0052] An embodiment of the present invention provides a thermal management system for a power battery of an electric vehicle, the structural diagram of which is shown in figure 1 As shown, the electric vehicle power battery thermal management system includes: a first cooling circuit 1 , a second cooling circuit 2 and a heating film 3 .

[0053] Wherein, the first cooling circuit 1 is suitable for cooling the power battery 4 whose temperature is higher than the first threshold value through the coolant, and the first cooling circuit 1 includes a refrigeration exchanger 102 and a water pump 103 connected with an air-conditioning refrigerant circulation branch 101. The refrigerant circulation branch 101 is provided with a compressor 1011 and a condenser 1012;

[0054] The second cooling circuit 2 is suitable for cooling the power battery 4 whose temperature is higher than the second threshold and lower than the first threshold through the coolant, and the second cooling circuit ...

Embodiment 2

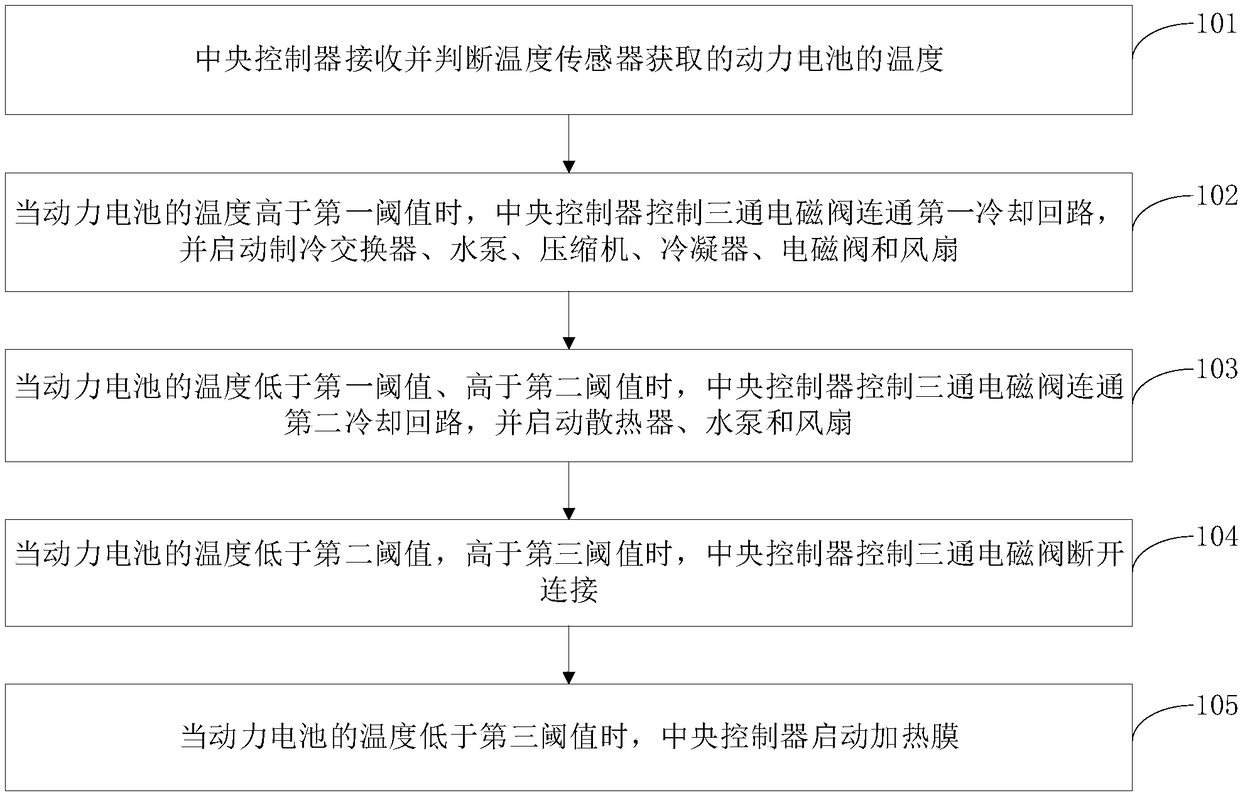

[0082] An embodiment of the present invention provides a thermal management method for a power battery of an electric vehicle, which is combined with a thermal management system for a power battery of an electric vehicle to realize thermal management of the power battery 4. The flow chart of the method is as follows figure 2 As shown, the details are as follows:

[0083] Step 101: the central controller receives and judges the temperature of the power battery 4 obtained by the temperature sensor;

[0084] Specifically, the temperature sensor can sense the temperature of the power battery 4 in real time, regardless of whether the power battery 4 is in a charging state or a discharging state.

[0085] It should be noted that the temperature sensor measures the average temperature of the power battery 4 .

[0086] Step 102: When the temperature of the power battery 4 is higher than the first threshold, the central controller controls the three-way solenoid valve 5 to communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com