Integrated heat dissipation type motor system

A technology that integrates heat dissipation and blowing fans. It is used in electrical components, electromechanical devices, and electric components. It can solve the problems of difficult to meet the requirements of heat exchange, low economy, and difficult maintenance, and achieve compact structure, reasonable layout, The effect of increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can better understand and implement the solution.

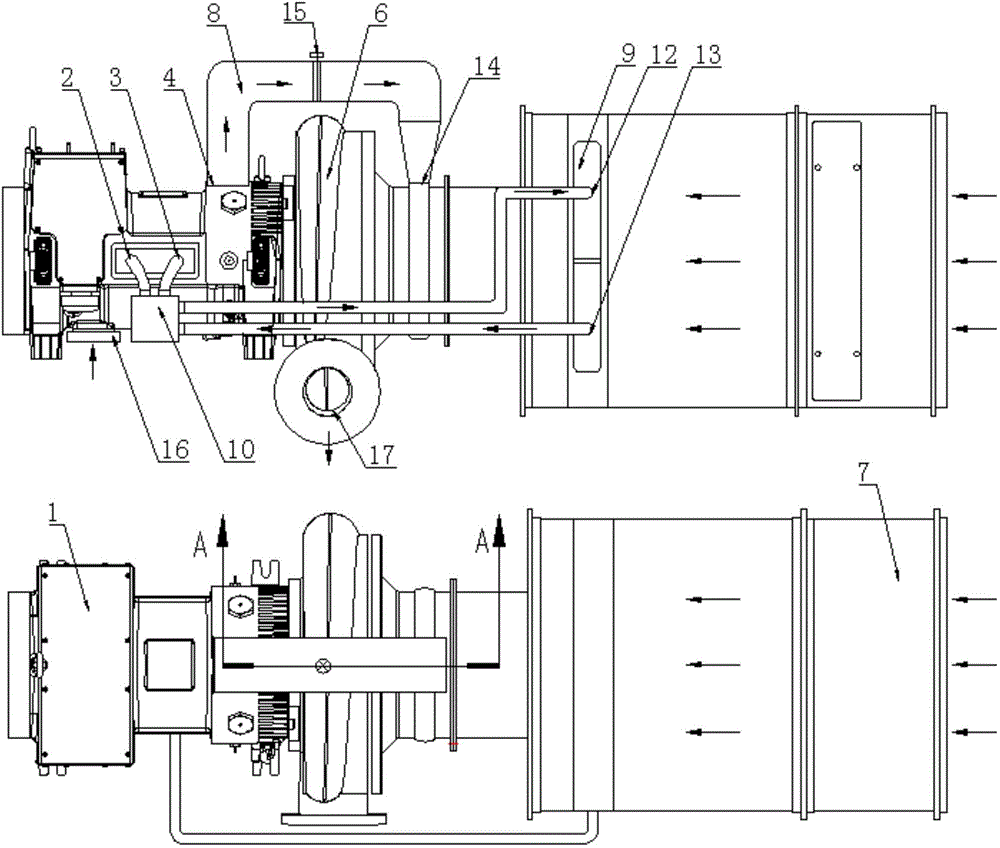

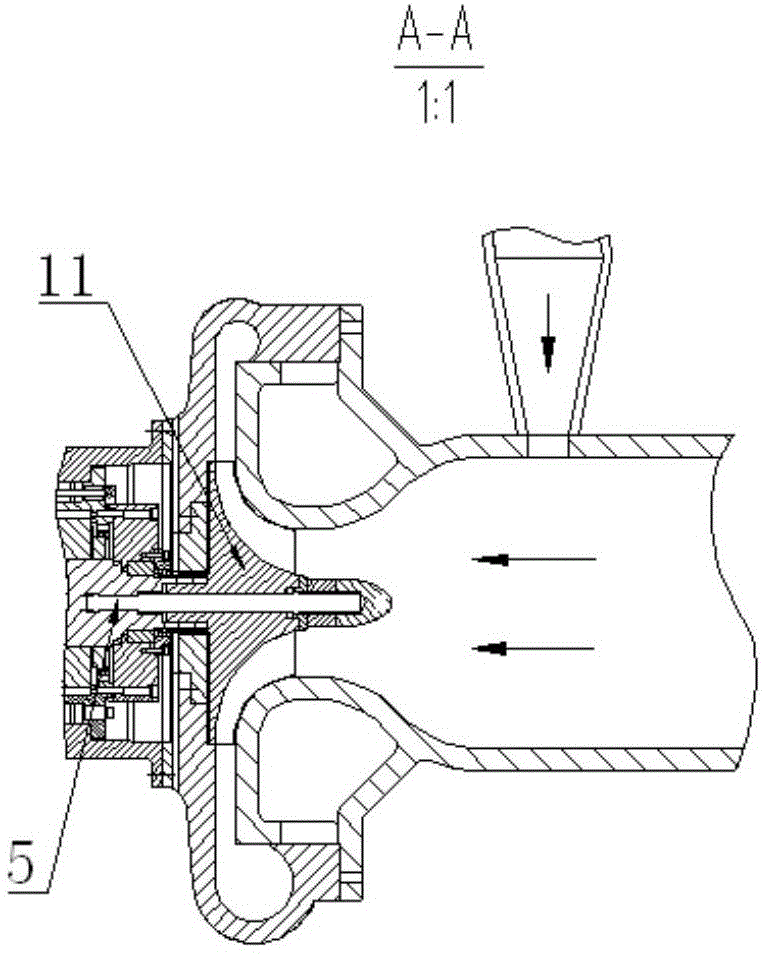

[0012] as attached figure 1 , attached figure 2 As shown, the integrated heat dissipation motor system includes a motor 1 with a coolant inlet 2, a coolant outlet 3, an air outlet 4 and a main shaft 5, and is characterized in that it also includes a blower fan 6, a filter muffler 7, an Air flow channel 8, heat exchanger 9, coolant circulation pump 10, impeller 11, motor 1 and pressure blower 6 are connected through flanges, impeller 11 is set on the main shaft 5 of motor 1, pressure blower 6 and filter silencer 7 Through the flange connection, the heat exchanger 9 is sealed and set in the filter muffler 7, and the coolant circulation pump 10 is respectively connected with the coolant inlet 2 and the coolant outlet 3 of the motor 1, and the coolant inlet A12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com