Degumming device for crystalline silicon waste recovery

A waste recycling and crystalline silicon technology, applied in the fields of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of substandard purity of polycrystalline silicon ingots, inability to produce semiconductor materials, and the quality of degumming can not meet the requirements. The effect of heat dissipation, reducing heat dissipation, and quick discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

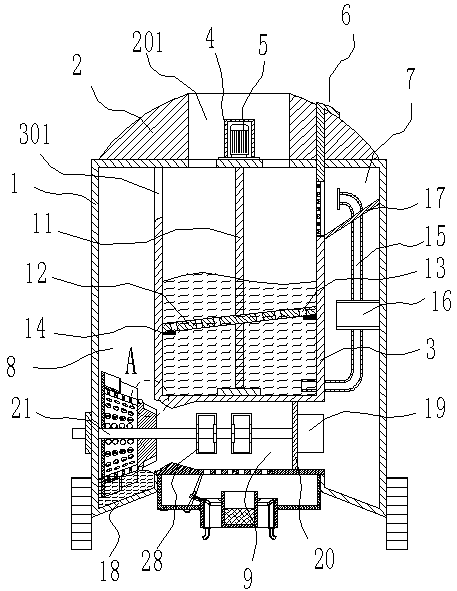

[0032] Such as Figure 1-Figure 10 As shown, the specific structure of the present invention is as follows: comprising an arc-shaped upper cover 2, the lower end of the upper cover 2 is provided with a body 1, and it is characterized in that a cleaning cylinder 3 and a mounting frame 20 are arranged in the body 1 to separate the body 1 It is a clean room 7, a wet degumming chamber 8 and a combustion degumming chamber 9, the wet degumming chamber 8 is provided with a degumming liquid, and the bottom of the burning degumming chamber 9 is provided with a burner 39; the body The upper end of 1 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com