A kind of pretreatment and application method of phosphogypsum

A phosphogypsum and pretreatment technology, applied in the field of phosphorus chemical industry, can solve the problems of large water consumption, high cost and high cost of the washing method, achieve the improvement of uniaxial compressive strength, improve the utilization rate of resources, and reduce the release of harmful components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

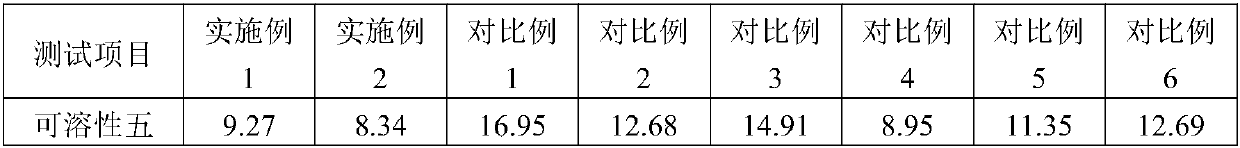

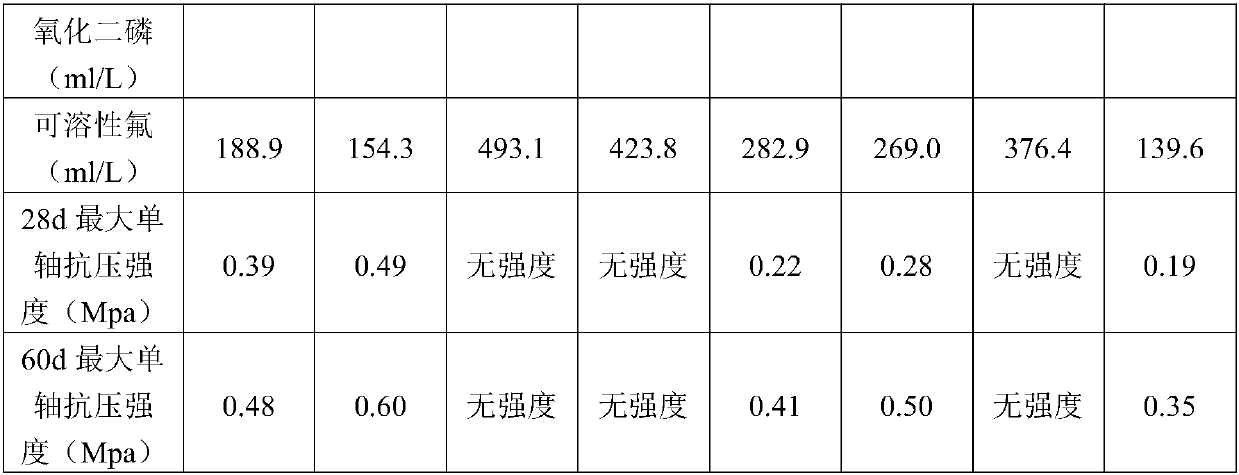

Embodiment 1

[0043] Step 1: Weigh 3500g of phosphogypsum, 3713.5g of tap water and 126g of industrial heavy calcium powder into a container. The amount of industrial heavy calcium powder is 4% of the mass of phosphogypsum. Stir for 5 minutes at a speed of 200rpm with a mixer to obtain a phosphogypsum material slurry, at this time pH=3.03;

[0044] Step 2: Put the phosphogypsum slurry in step 1 to stand and age for 3 hours to fully react, and the pH at this time is 2.67.

[0045]Step 3: Add 787.5 g of gelling agent to the phosphogypsum slurry in the container in step 1 according to the mass ratio of phosphogypsum and gelling agent at a ratio of 4:1, and stir at 200 rpm for 30 to 45 minutes using a mixer to obtain Filling slurry with a mass concentration of 50%;

[0046] Step 4: pour the filling slurry in step 3 into a mold to prepare a filling sample.

Embodiment 2

[0048] Step 1: Weigh 3500g of phosphogypsum, 3839.5g of tap water and 252g of industrial heavy calcium powder into a container. The amount of industrial heavy calcium powder is 8% of the mass of phosphogypsum. Use a mixer to stir at a speed of 200rpm for 5min to obtain a phosphogypsum material Slurry, at this time pH=3.24;

[0049] Step 2: Put the phosphogypsum slurry in step 1 to stand and age for 3 hours to fully react, and the pH at this time is 3.38.

[0050] Step 3: Add 787.5 g of gelling agent to the phosphogypsum slurry in the container in step 1 according to the mass ratio of phosphogypsum and gelling agent at a ratio of 4:1, and stir at 200 rpm for 30 to 45 minutes using a mixer to obtain Filling slurry with a mass concentration of 50%;

[0051] Step 4: pour the filling slurry in step 3 into a mold to prepare a filling sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com