Preparation method of low-chloride plastic pyrolysis oil

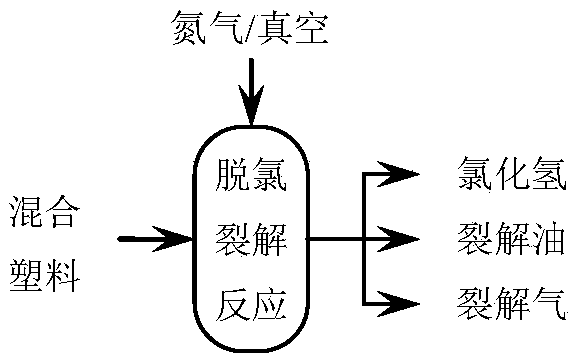

A technology for cracking oil and plastics, applied in the field of preparation of low-chlorine plastic cracking oil, can solve the problems of high reactor cost, difficult implementation, low dechlorination efficiency, etc., and achieve the effect of simple equipment and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

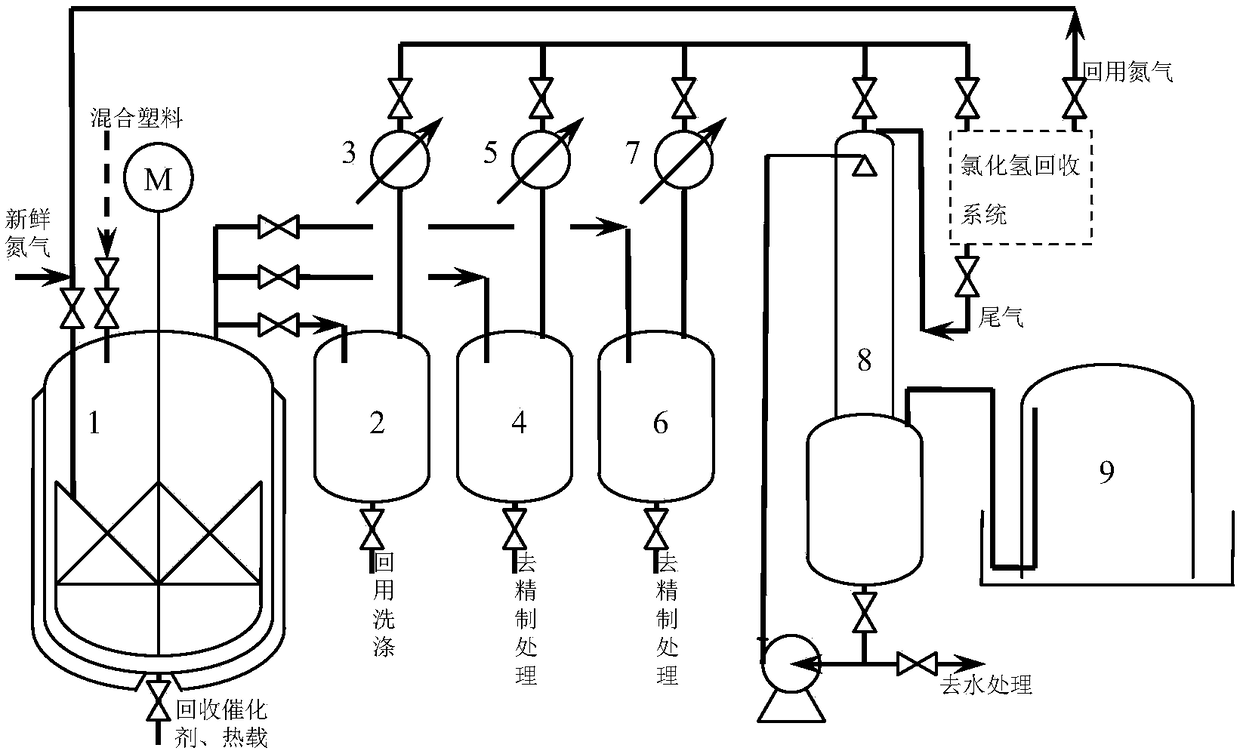

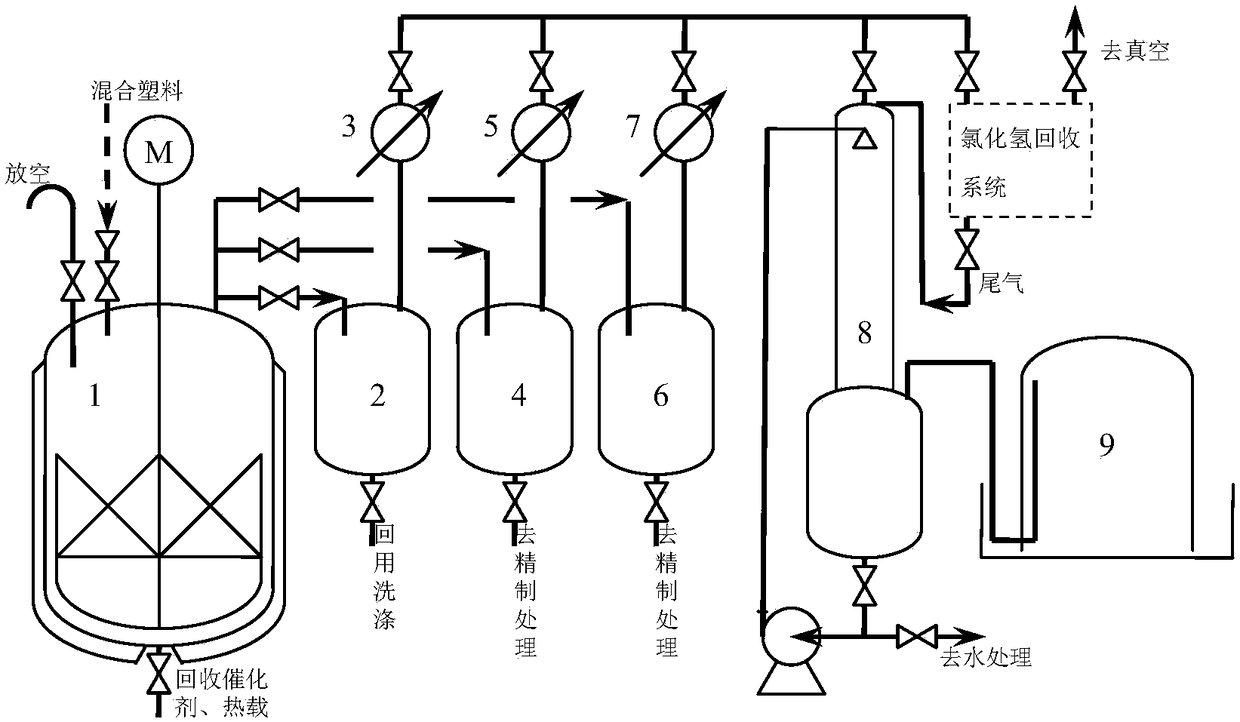

Embodiment 1

[0028] Mix and crush 0.5kg of cleaned PVC plastic, 2.3kg of PP plastic, 2.3kg of PS plastic, and 4.9kg of PE plastic to less than 5mm 3 Add 0.5kg heat-loaded 80-mesh quartz sand into 50L dechlorination cracking reactor 1, and start the first reaction temperature section to heat up under stirring, with a heating rate of 3-8°C·min -1 , kept at the final temperature of 250°C for 2-3 hours, mixed plastics at this temperature section for melting and dehydration; the released water was cooled to the first storage tank 2 by the first condenser 3, and the non-condensable gas was washed by the scrubber 8, and then Enter the gas storage tank 9 for storage. The final temperature insulation of the first reaction temperature section is over, and the second reaction temperature section is started to heat up, and at the same time, 0.5L·s is added to the dechlorination cracking reactor 1. -1 Nitrogen gas is passed at a rate, and the heating rate is 3-8°C·min -1 , keep at the final temperatu...

Embodiment 2

[0030] Mix and crush 1.0kg of cleaned PVC plastic, 2.15kg of PP plastic, 2.15kg of PS plastic and 4.7kg of PE plastic to less than 5mm 3 Add 0.5kg heat-loaded 80-mesh quartz sand into 50L dechlorination cracking reactor 1, and start the first reaction temperature section to heat up under stirring, with a heating rate of 3-8°C·min -1 , kept at the final temperature of 250°C for 2-3 hours, mixed plastics at this temperature section for melting and dehydration; the released water was cooled to the first storage tank 2 by the first condenser 3, and the non-condensable gas was washed by the scrubber 8, and then Enter the gas storage tank 9 for storage. The final temperature insulation of the first reaction temperature section is over, and the second reaction temperature section is started to heat up, and at the same time, the dechlorination cracking reactor 1 is filled with 1.5L·s -1 Nitrogen gas is passed at a rate, and the heating rate is 3-8°C·min -1, keep at the final tempera...

Embodiment 3

[0032] Mix and crush 2kg of cleaned PVC plastic, 1.9kg of PP plastic, 1.9kg of PS plastic, and 4.2kg of PE plastic to less than 5mm 3 Add 1.5kg of hot-loaded 100-mesh quartz sand into the 50L dechlorination cracking reactor 1. Under stirring, start the first reaction temperature section to raise the temperature, and the heating rate is 3-8°C·min -1 , kept at the final temperature of 250°C for 2-3 hours, mixed plastics at this temperature section for melting and dehydration; the released water was cooled to the first storage tank 2 by the first condenser 3, and the non-condensable gas was washed by the scrubber 8, and then Enter the gas storage tank 9 for storage. The final temperature insulation of the first reaction temperature section is over, and the second reaction temperature section starts to heat up, and at the same time, 2.5L·s is added to the dechlorination cracking reactor 1. -1 Nitrogen gas is passed at a rate, and the heating rate is 3-8°C·min -1 , keep at the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com