Single-line railway tunnel anti-rock-burst support method corresponding to different rock burst intensity levels

A single-track railway, rockburst technology, applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problem of lack of rockburst-proof support structure system, and achieve the effect of ensuring stability and safety, and strong practical operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

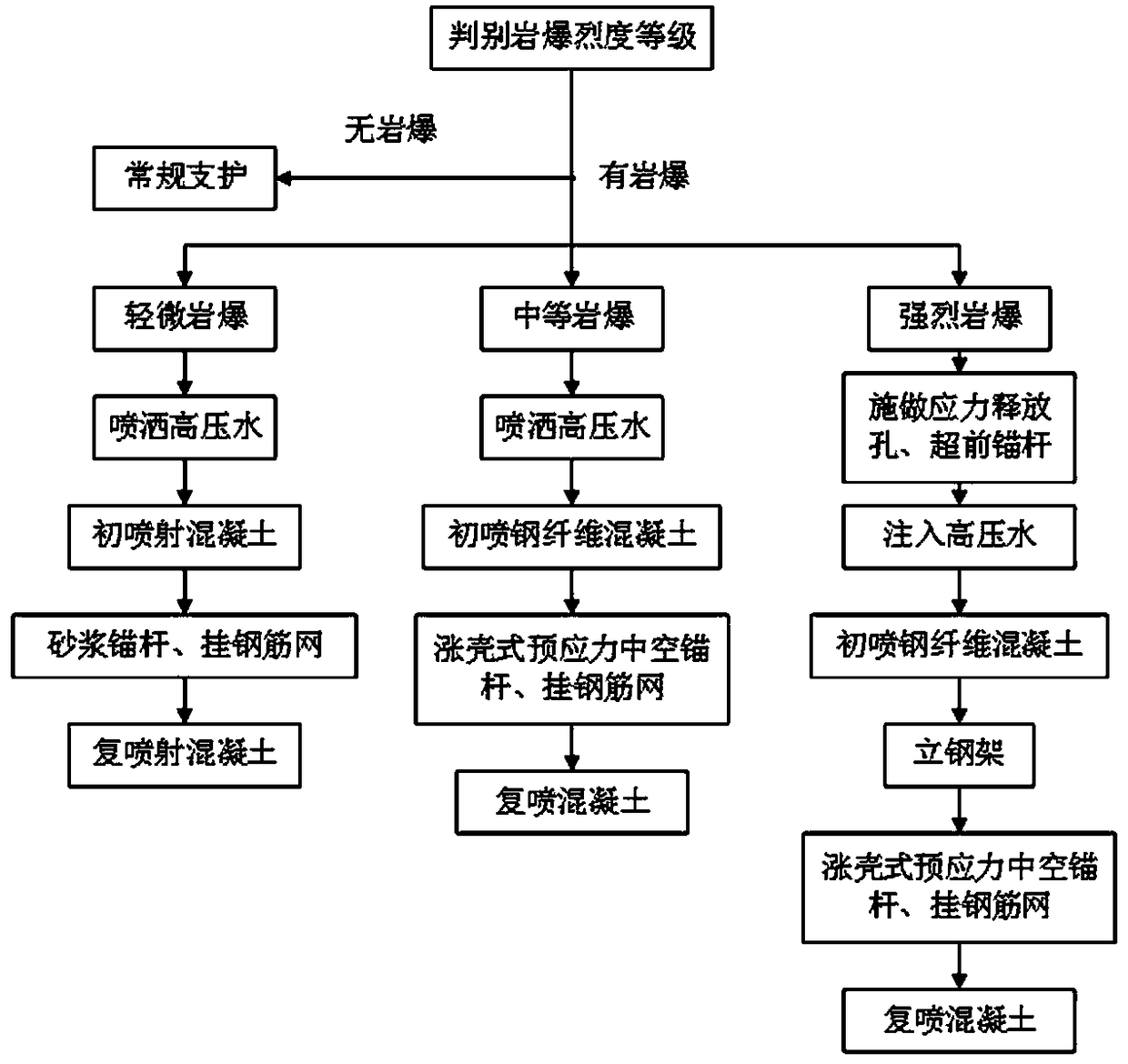

[0024] The explosive intensity level is judged according to existing methods such as advanced geological forecast, microseismic monitoring and site characteristics:

[0025] The specific support steps for the minor rockburst section are as follows. The excavation cycle footage of the tunnel is controlled to be 3m. After each cycle of excavation, blasting, risk removal and slag discharge, ①spray high-pressure water on the face of the tunnel and the wall of the tunnel to soften the surface to release the surrounding rock. rock stress. ②After the rockburst state basically subsided, the initial spraying of C25 concrete was carried out on the excavation surface to play the role of initial support. ③The arch wall is set with 2m long Φ22 mortar anchor rods, with a spacing of 2m×2m (ring×longitudinal), and φ6 steel mesh is hung with a grid spacing of 25×25cm. ④ Re-spray C25 concrete to the design thickness.

[0026] The specific support steps for the moderate rockburst section are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com