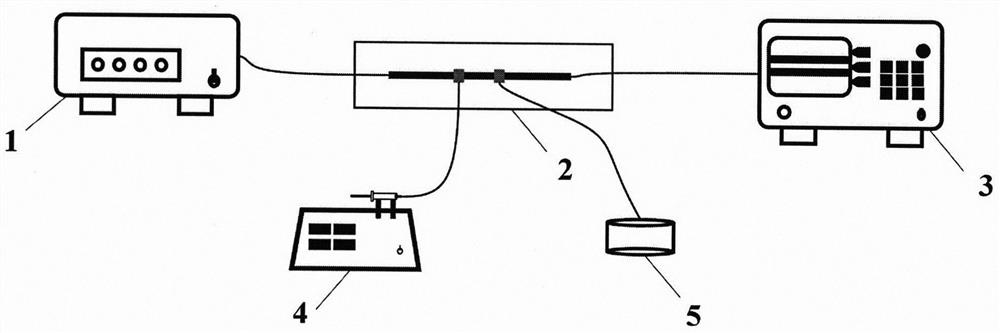

In-fiber microfluidic sensing device based on four-hole microstructure optical fiber integration

A technology of micro-structured optical fiber and sensor devices, which is applied in optical components, optical waveguide coupling, instruments, etc., can solve the problems of sensitivity limitation and interference, and achieve the effect of high sensitivity, simple manufacture and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

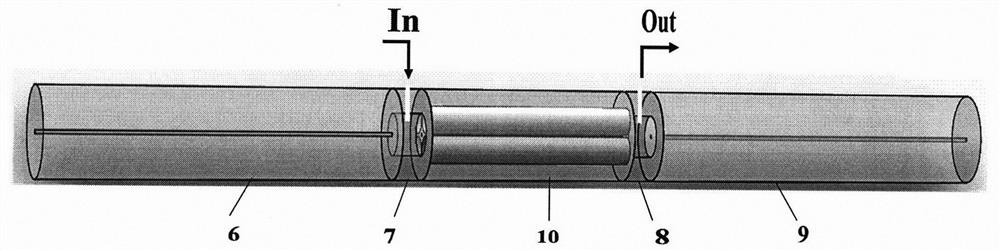

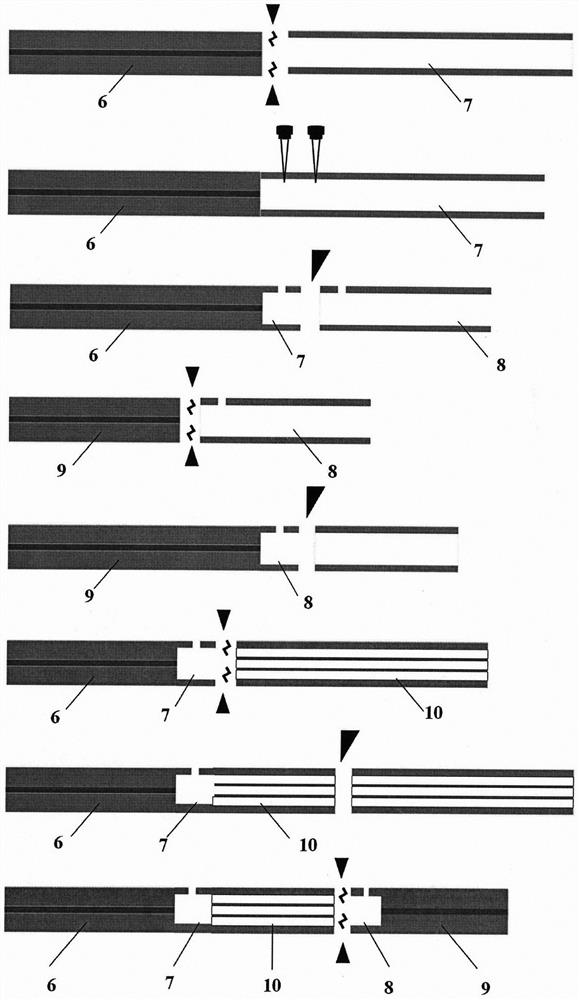

[0021] This example uses an in-fiber microfluidic sensor device based on the integration of four-hole microstructured optical fibers to measure the refractive index of liquid. When the light of the supercontinuum light source enters the left open-hole capillary fiber through the input single-mode fiber, the high-order mode is excited, and the high-order mode and the core mode are simultaneously transmitted in the core and cladding of the four-hole microstructure fiber. The refractive index of the core and the cladding of the four-hole microstructure fiber is different, and the propagation constants of the high-order mode and the core fundamental mode in the fiber are different, so that different modes of light have different optical paths. Therefore, in the four-hole microstructure fiber fiber Light propagating between the core and cladding also has an optical path difference, resulting in a phase difference between the higher-order modes and the core fundamental mode. When th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com