Phase change cold condensation device

A phase-change, connected technology, applied in damage protection, fixed tubular conduit assemblies, lighting and heating equipment, etc., to achieve high heat exchange efficiency, low operating costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

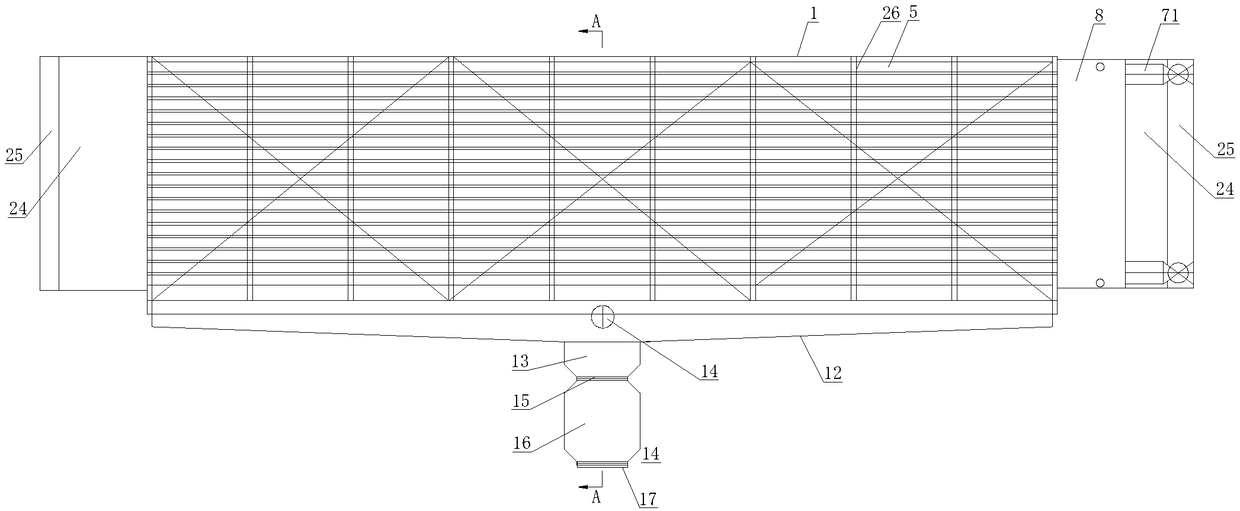

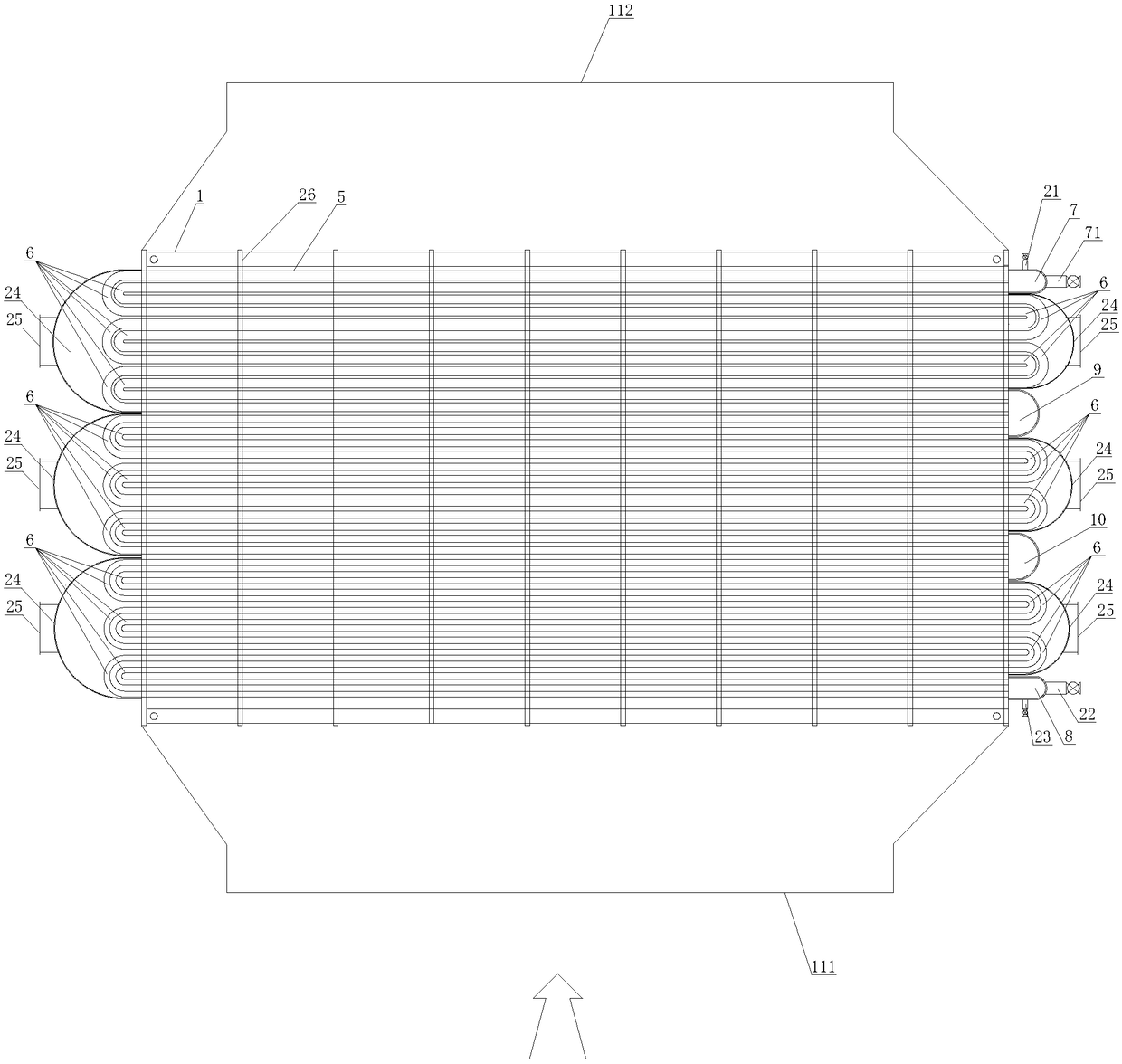

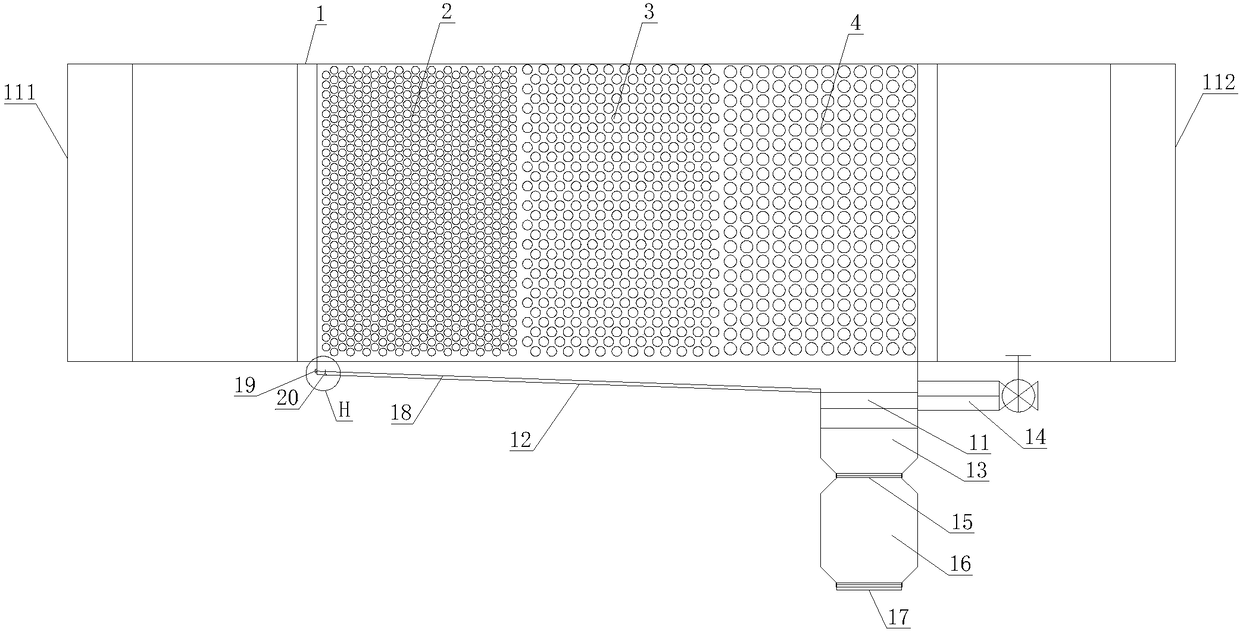

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the phase change condensation condensation device includes a heat exchange shell 1, and a smoke inlet 111 and a smoke outlet 112 are respectively arranged on the front and rear sides of the heat exchange shell 1. The interior of the body 1 is provided with a primary heat exchange unit 2, a secondary heat exchange unit 3 and a tertiary heat exchange unit 4 in sequence along the flue gas flow direction. Since the primary heat exchange unit 2, the secondary heat exchange unit 3 and the tertiary The structures of the heat exchange units 4 are all the same, and the structure of the first-stage heat exchange unit 2 is used as an example for illustration below. The structure of the first-stage heat exchange unit includes: several rows are supported on the heat exchange shell 1 from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com