Full-automatic fatty acid value detection system and detection method

A fully automatic technology for fatty acid value detection, applied in the direction of analysis materials, instruments, etc., can solve the problems of high operating level requirements of experimental analysts, failure to meet the needs of batch sample detection, and no automatic sample injection analysis, etc., to ensure repeatability performance and accuracy, enabling continuous titration detection, and improving single-sample processing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0038] The invention discloses a fully automatic fatty acid value detection system, which is used to detect the fatty acid value of the extract liquid, which is mainly the grain extract liquid, and can realize the full automation of conveying the extract liquid to the detection. The following is a specific embodiment:

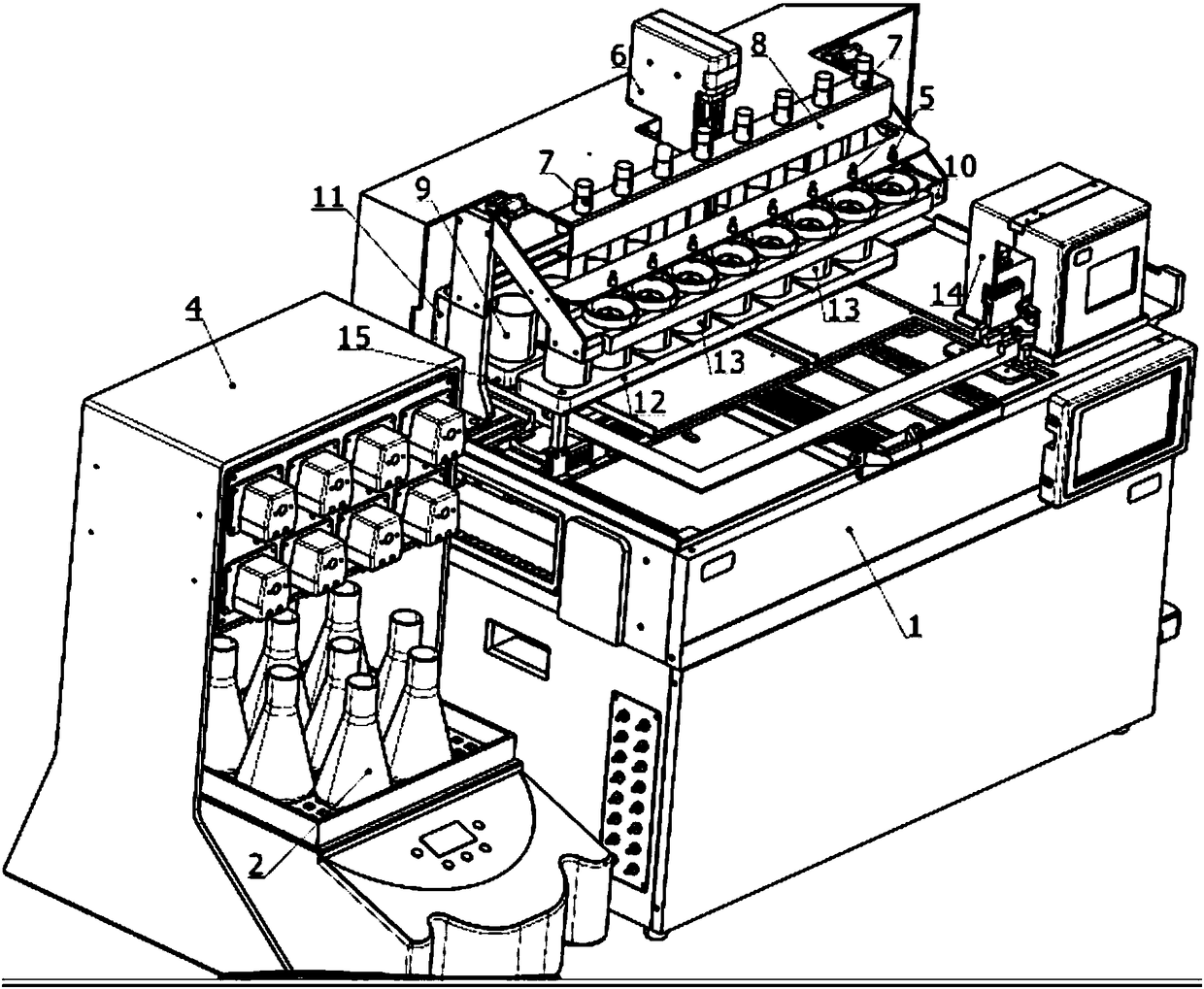

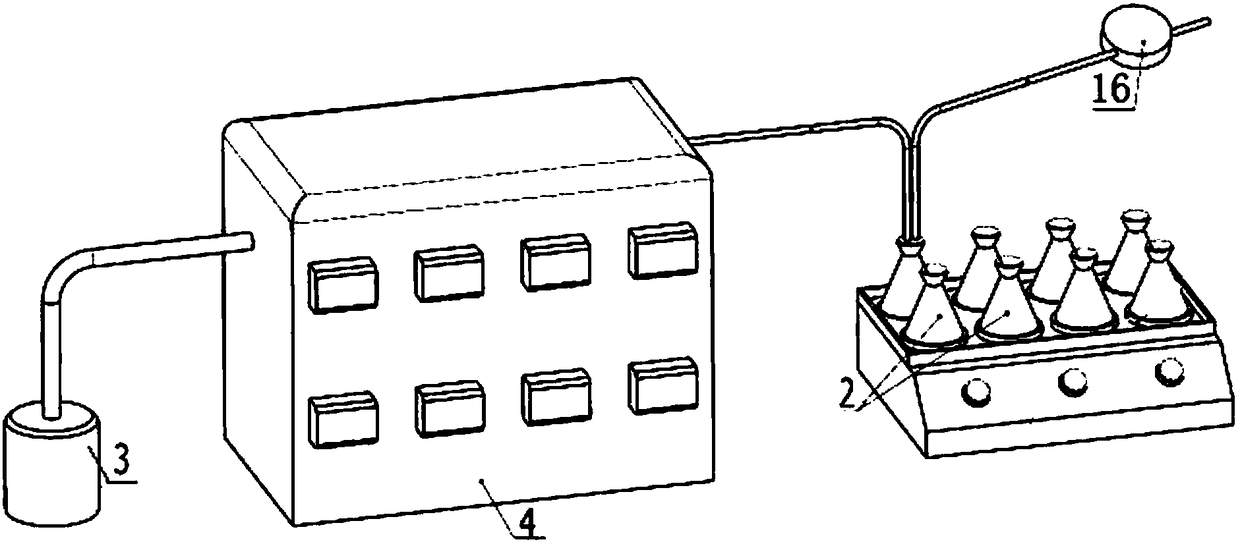

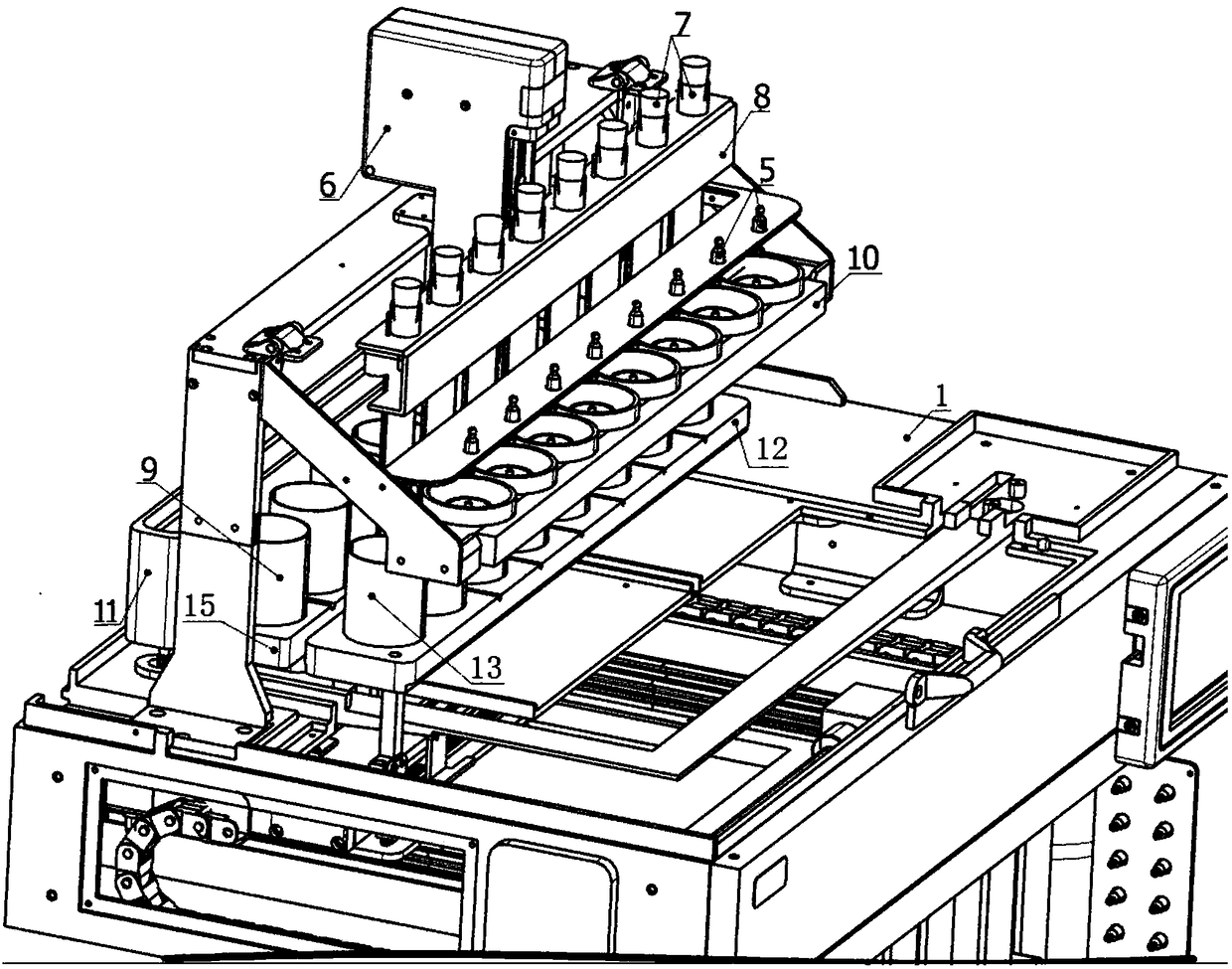

[0039] A kind of automatic fatty acid value detection system among the present invention, as figure 1 As shown, it includes a titration pre-processing part, a quantitative liquid addition part set at one end of the workbench and a continuous spectroscopic titration analysis part at the other end, and also includes a quantitative transfer for transferring samples from the quantitative liquid addition part to the titration analysis part device. The titration pretreatment part is used for stirring the sample, and the titration pret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com