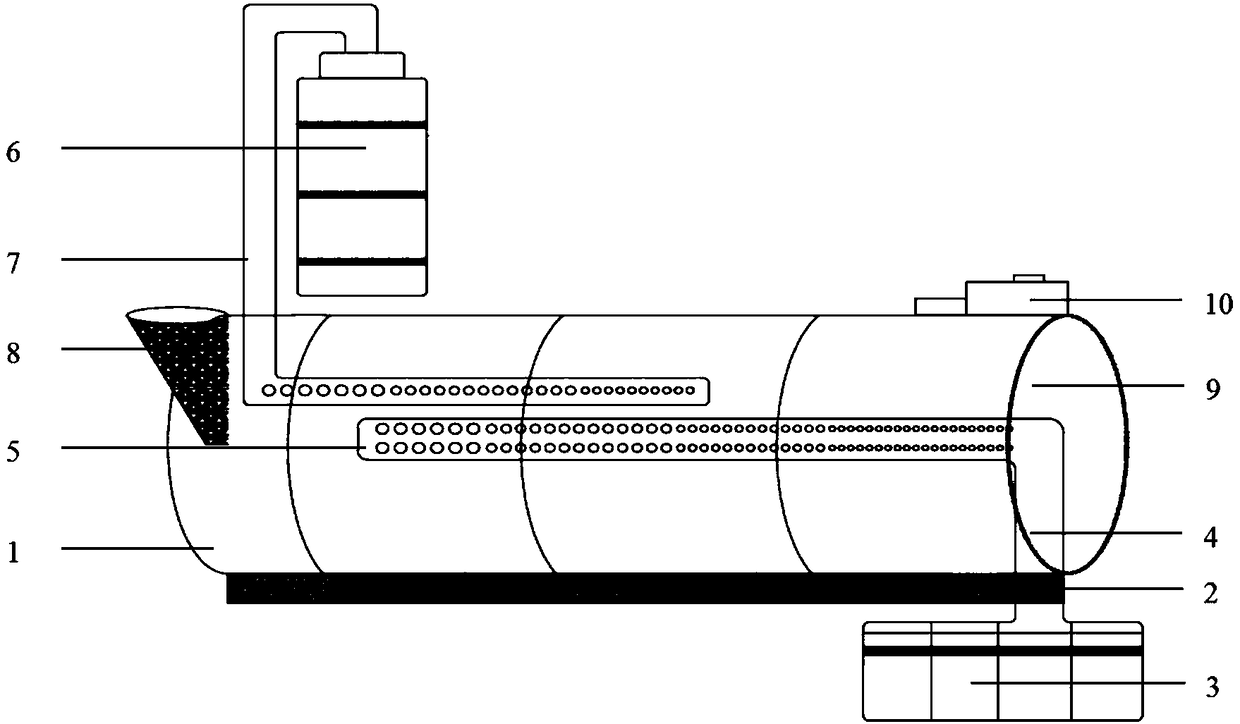

Three-phase combined type enzyme deactivating device and enzyme deactivating method thereof

A green killing device and a combined technology, applied in the field of food processing, can solve the problems of excitation, the existence of temperature difference, the deviation of the effect of killing green and killing enzymes, etc., and achieve the effect of strong steam penetration, good quality uniformity, and retention of greenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

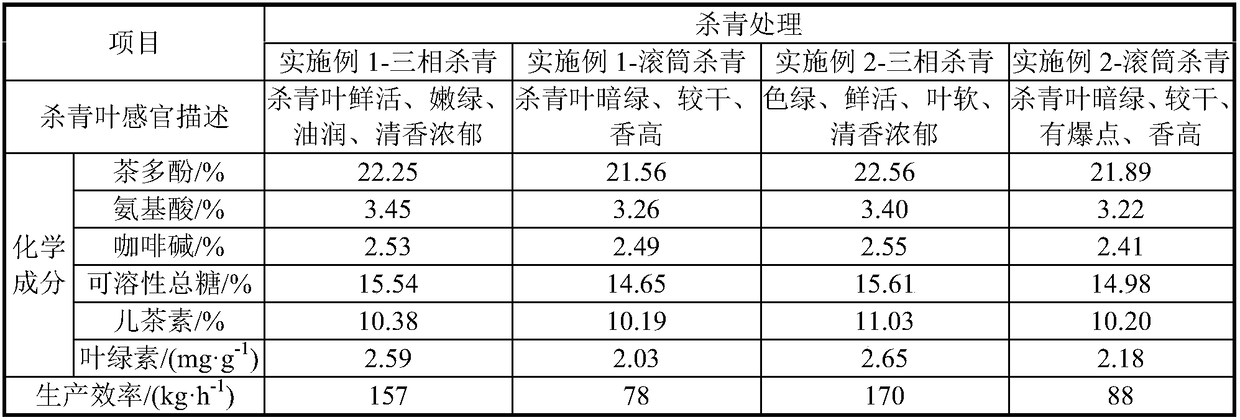

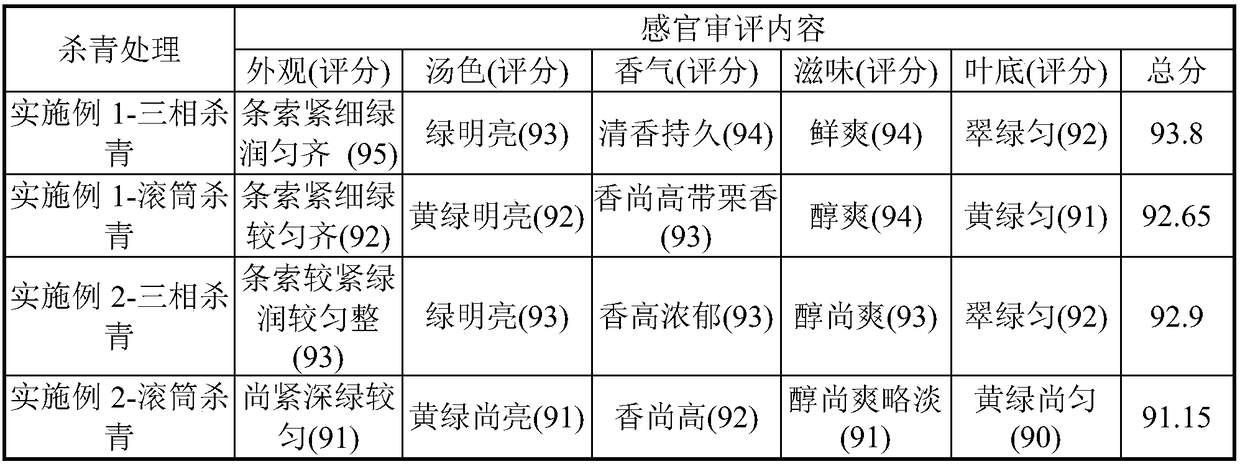

Embodiment 1

[0042] A kind of raw material that a kind of three-phase combined type fixation method selects is: the kind is Fuding Dabai, and the tenderness is 50Kg of the spread green leaves of single bud-1 bud and 1 leaf.

[0043] The specific implementation is as follows:

[0044] (1) The drum is heated by electromagnetic means, and the temperature of the three-stage drum is respectively set to 250°C, 230°C, and 190°C; at the same time, the steam generating device is started to let the steam fill the cleaning cavity through the conveying pipeline, and focus on the cleaning The first 2 / 3 of the cavity; start the hot air generating system, set the temperature to 190°C, let the hot air pass through the conveying pipe and basically cover the entire cleaning cavity (the front end is slightly shorter); at the same time, adjust the single cycle time of cleaning by the speed of the drum to 75± 3s, the speed is 20 rpm. After the drum temperature, hot air temperature, steam, etc. are balanced, f...

Embodiment 2

[0047] A kind of raw material that a kind of three-phase combined type fixation method selects is: the kind is Fuding Dabai, and the tenderness is 1 bud 1 leaf-1 bud 2 leaves and spread green leaves 50Kg that just unfolded.

[0048] (1) The drum is heated by electromagnetic means, and the temperature of the three-stage drum is respectively set to 260°C, 240°C, and 190°C; at the same time, the steam generating device is started to let the steam fill the cleaning cavity through the conveying pipeline, and focus on the cleaning The first 2 / 3 of the cavity; start the hot air generating system, set the temperature to 190°C, let the hot air pass through the conveying pipe and basically cover the entire cleaning cavity (the front end is slightly shorter); at the same time, adjust the single cycle time of cleaning by the speed of the drum to 75± 3s, the speed is 20 rpm. After the drum temperature, hot air temperature, steam, etc. are balanced, fresh leaves can be put in from the leaf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com