A method for drying tobacco leaves of flue-cured tobacco varieties

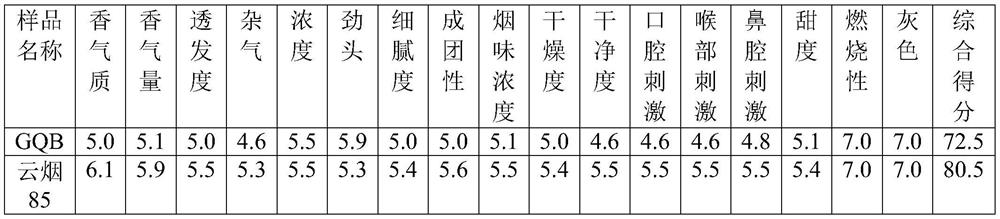

A technology of flue-cured tobacco varieties and production methods, which is applied in the field of tobacco, can solve the problems of no mature technical solutions, etc., and achieve the effect of small miscellaneous gas, meeting the demand, and obvious aroma characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The flue-cured tobacco plant is Yunyan 85.

[0027] Harvesting tobacco leaves: Harvest and sun-cure by cutting the plants in half, and take the tobacco leaves above the middle (remove the top leaves). Tobacco leaf harvesting standard: leaf color is chlorotic and fully yellow, mature, main veins and branches are all white, leaf wrinkles, mature spots protruding, showing yellow-white blisters, leaf ears turn yellow, leaf tips droop, leaf margins roll down, fluff fall off.

[0028] Immediately after the tobacco leaves are harvested, they are hung in the shed for drying. The drying racks used to hang the flue-cured tobacco plants in the drying shed shall be built according to the following requirements:

[0029] Prepare several long bamboo poles for hanging flue-cured tobacco plants. The actual number depends on the size of the awning. Reserve a section at both ends of each bamboo pole for hanging. 7 holes with a spacing of 20cm. Each hole is fixed with a wire hook, and ...

Embodiment 2

[0036] The flue-cured tobacco plant is Yunyan 87. Tobacco leaf harvesting method and standard are the same as in Example 1. The method of building the drying rack in the sun shed is the same as in Example 1.

[0037] After the drying rack is built, the flue-cured tobacco plants are hung upside down on the iron hooks. After the hanging is completed, the drying begins. The drying stage includes four stages: withering period, yellowing period, color fixing period and tendon drying period. The control conditions of each stage as follows:

[0038] Withering period: The ventilating and dehumidifying windows of the drying shed are fully opened during the day and closed at night. The humidity in the shed is controlled at 90% and the temperature is 30°C. After drying for 36 hours, it is observed that the leaves become soft and withered, and the tips and edges of the leaves turn yellow. move on to the next stage;

[0039] Yellowing period: the distance between adjacent long bamboo po...

Embodiment 3

[0043] The flue-cured tobacco plant is Honghua Dajinyuan. Tobacco leaf harvesting method and standard are the same as in Example 1. The method of building the drying rack in the sun shed is the same as in Example 1.

[0044] After the drying rack is built, the flue-cured tobacco plants are hung upside down on the iron hooks. After the hanging is completed, the drying begins. The drying stage includes four stages: withering period, yellowing period, color fixing period and tendon drying period. The control conditions of each stage as follows:

[0045] Withering period: The ventilating and dehumidifying window of the drying shed is fully opened during the day and closed at night. The humidity in the shed is controlled at 90% and the temperature is 25°C. After drying for 2 days, it is observed that the leaves become soft and withered, and the tips and edges of the leaves turn yellow. , enter the next stage;

[0046] Yellowing period: the distance between adjacent long bamboo pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com