Biological fire extinguishing agent

A fire extinguishing agent and bio-based technology, which is applied in fire prevention equipment and other fields, can solve the problems of biological pollution of fluorocarbon surfactants, and achieve the effects of low production cost, low environmental pollution, and low biological hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

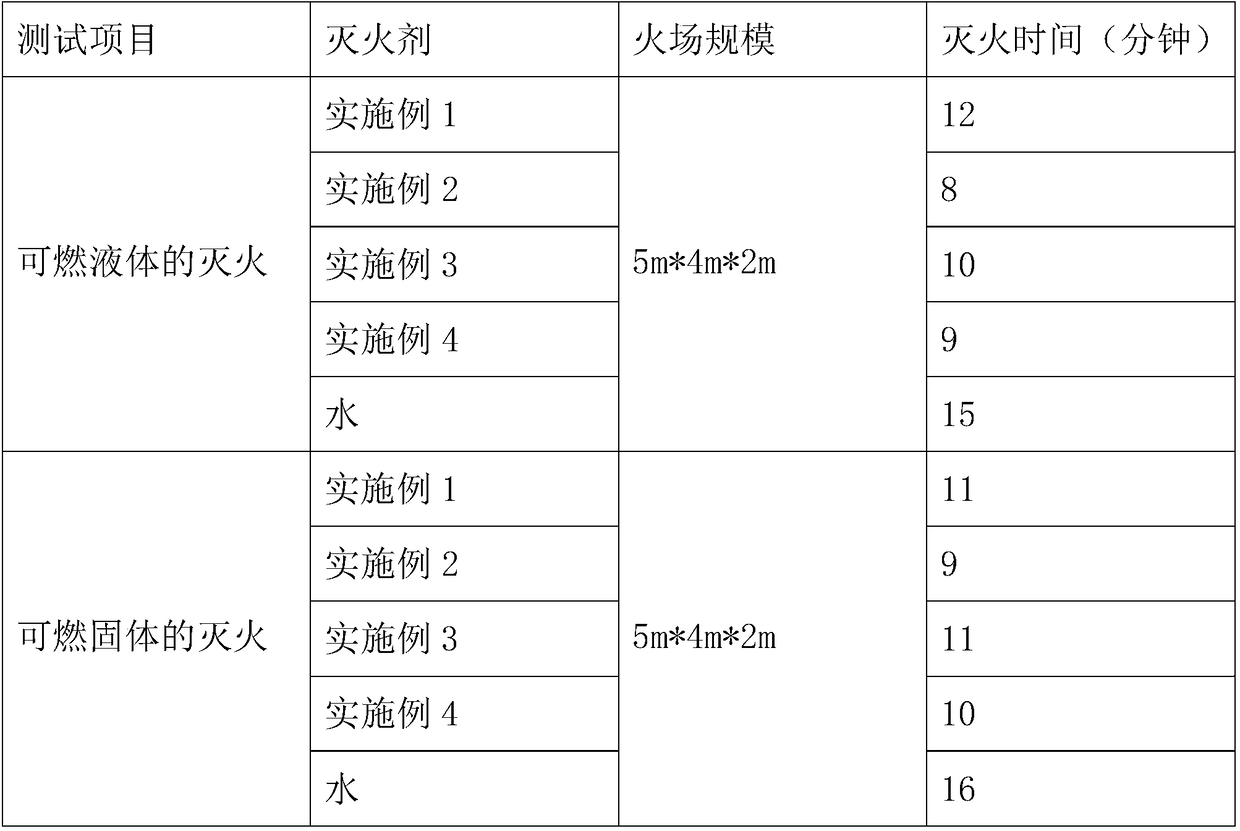

Examples

Embodiment 1

[0021] (1) The dried animal hairs with 100 parts by mass are pulverized with a high-speed pulverizer until the chicken feathers are crushed to an average particle size lower than 5 mm, then 4 parts of protease and 800 parts of tap water are added, After high-speed stirring, the mixed liquid was obtained, and then sealed and fermented at 55°C for 5 days, then left to cool, filtered with a 800-mesh filter to obtain the filtrate, and concentrated under reduced pressure at 35°C to the volume of the original liquid 1 / 4-1 / 3 of that, this substance is the hair solution.

[0022] (2) Add 25 parts of amphoteric surfactant, 15 parts of nonionic surfactant, and 50 parts of hair solution into the reaction kettle, stir and mix at a high speed, and obtain a foam forming agent after mixing evenly.

[0023] (3) 25 parts by mass of ethylene glycol, 6 parts of propylene glycol, and 8 parts of glycerol are added into the reaction kettle for stirring, and what is obtained after stirring evenly is...

Embodiment 2

[0028] (1) The dried animal hair of 110 parts by mass is pulverized with a high-speed pulverizer until the chicken feathers are crushed to an average particle size lower than 5mm, then 4 parts of protease and 600 parts of tap water are added, After high-speed stirring, the mixed liquid was obtained, and then sealed and fermented at 55°C for 3 days, then left to cool, filtered with a 800-mesh filter to obtain the filtrate, and concentrated under reduced pressure at 35°C to the volume of the original liquid 1 / 4-1 / 3 of that, this substance is the hair solution.

[0029] (2) Add 24 parts of amphoteric surfactants, 16 parts of nonionic surfactants, and 45 parts of hair solution into the reaction kettle, stir and mix at a high speed, and obtain a foam forming agent after mixing evenly.

[0030] (3) 26 parts by mass of ethylene glycol, 5 parts of propylene glycol, and 7 parts of glycerol were added into the reaction kettle for stirring, and what was obtained after stirring evenly was...

Embodiment 3

[0035](1) The dried animal hair of 120 parts by mass is pulverized with a high-speed pulverizer until the chicken feathers are crushed to an average particle size lower than 5 mm, then 5 parts of protease and 1000 parts of tap water are added, After high-speed stirring, the mixed liquid was obtained, and then sealed and fermented at 55°C for 5 days, left to cool, filtered with a 800-mesh filter to obtain the filtrate, and concentrated under reduced pressure at 30°C to the volume of the original liquid 1 / 4-1 / 3 of that, this substance is the hair solution.

[0036] (2) Add 30 parts of amphoteric surfactants, 20 parts of nonionic surfactants, and 60 parts of hair solution into the reaction kettle, perform high-speed stirring and mixing, and obtain a foam forming agent after mixing evenly.

[0037] (3) Add 30 parts by mass of ethylene glycol, 8 parts of propylene glycol, and 10 parts of glycerol into the reaction kettle for stirring, and what is obtained after stirring evenly is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com