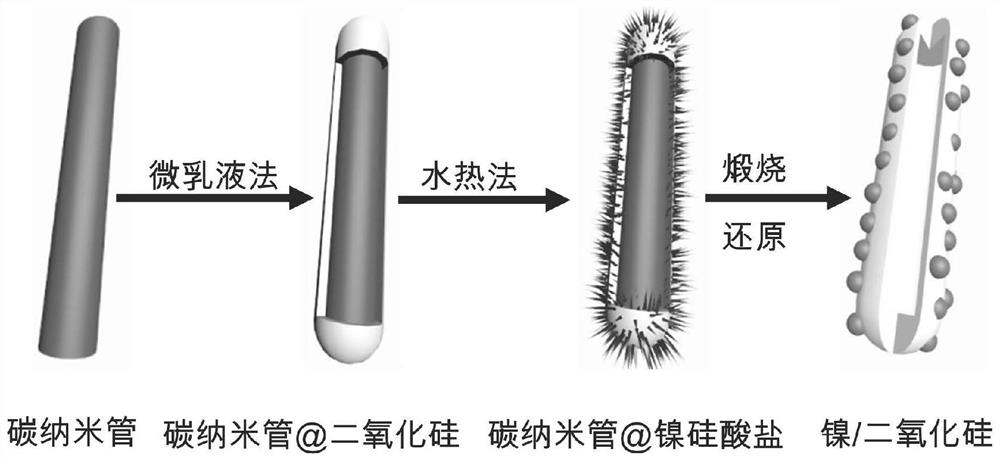

A highly dispersed silica nanotube-supported nickel catalyst and its preparation method

A technology of silica and nanotubes, which is applied in the field of highly dispersed silica nanotube-supported nickel catalysts and its preparation, can solve the problems of high dispersion catalysts and other problems, and achieve simple and rapid methods, easy-to-obtain synthetic raw materials, and high resistance to accumulation. The effect of carbon capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

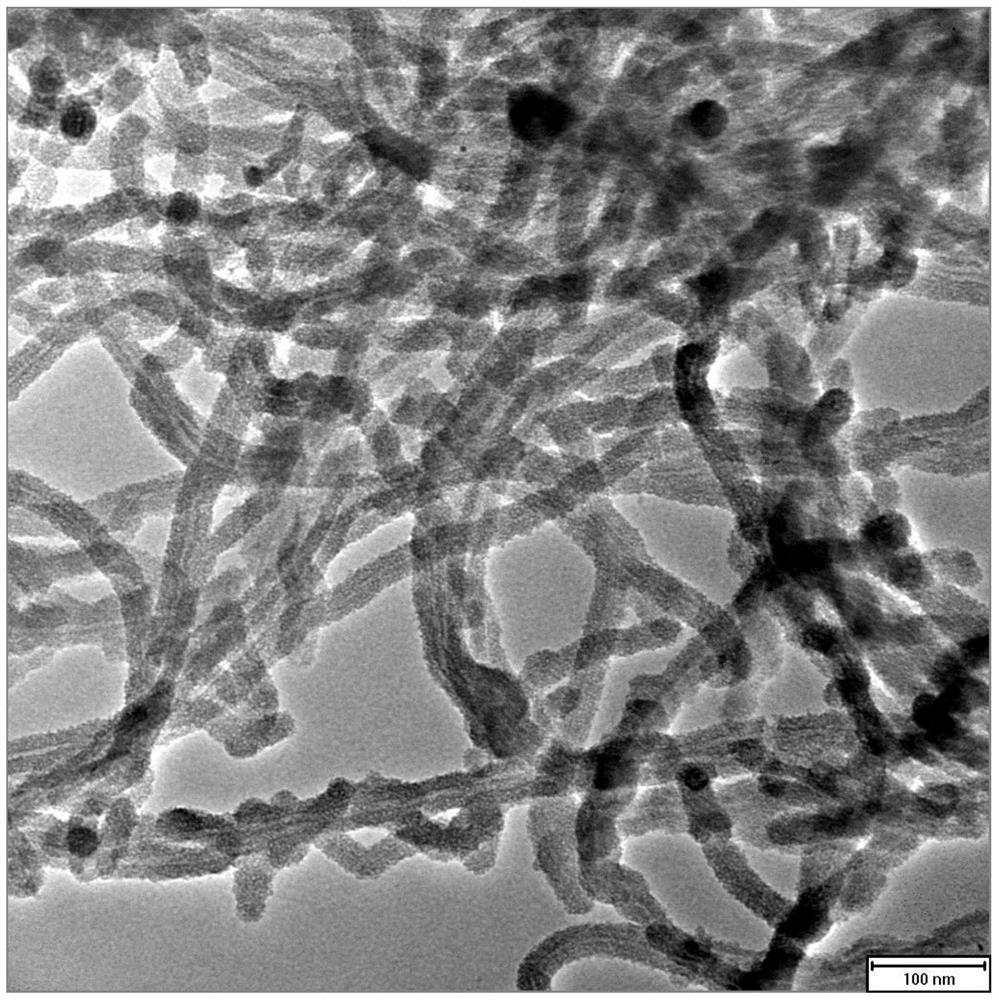

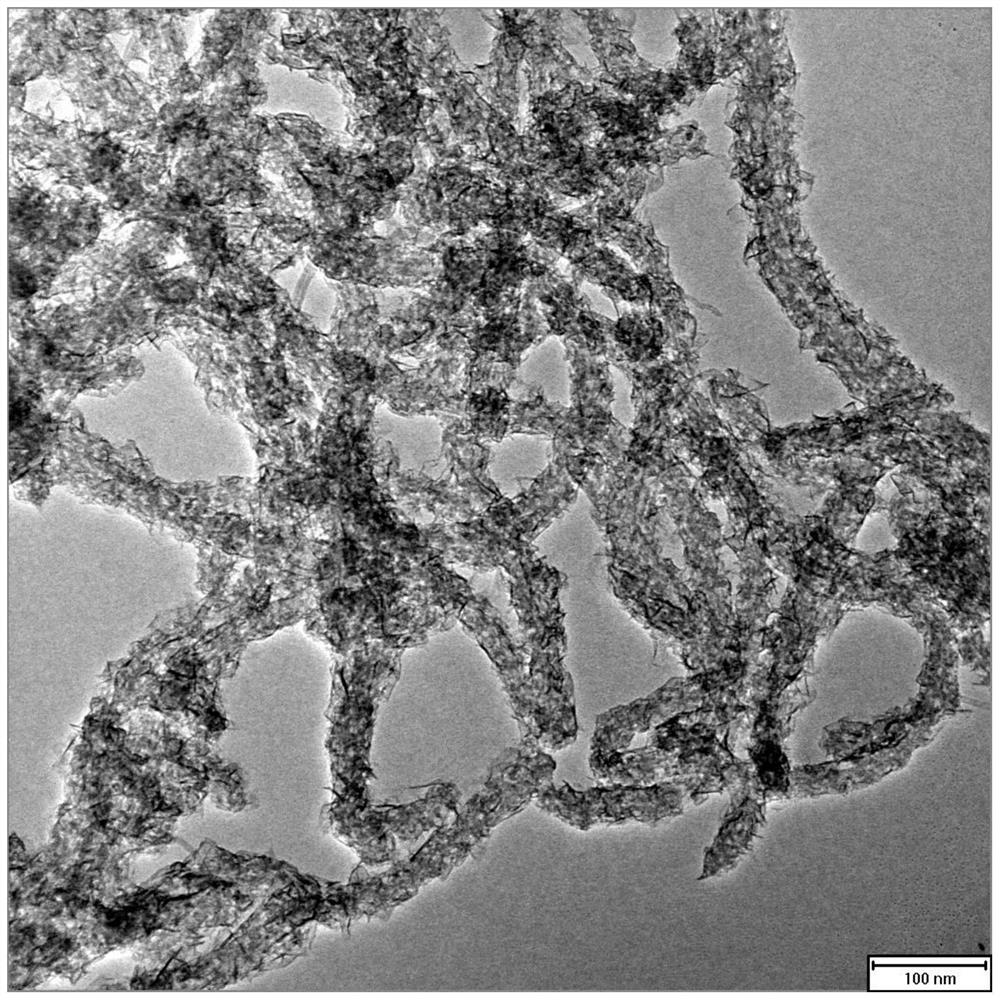

[0027] (1) Put 1 gram of carbon nanotubes into a 200ml flask, add 100ml of ethanol, 50ml of water, 6.9ml of ammonia (28wt%) and CTAB (concentration of 5g per liter) in sequence and stir well. Then, 1 mL of tetraethyl orthosilicate was added, reacted for 2 days, and centrifuged. After washing with a mixed solvent of ethanol and water, centrifuging, and drying at room temperature for 12 hours, a carbon nanotube@silica core-shell nanocomposite was obtained. Among them, the thickness of the silica nanotube shell is 10nm ( figure 2 ). XRD diffraction Figure 6 The diffraction pattern of middle b is at 23.5 o Diffraction peaks of silica appear. In addition, the intensity of the diffraction peak of the carbon nanotube becomes weak. These all indicate the successful synthesis of carbon nanotubes@silica core-shell structure.

[0028] (2) Add ammonia water to the carbon nanotube@silica core-shell composite obtained in the previous step, and 1 g of nickel nitrate, and adjust the p...

Embodiment 2

[0033] (1) Put 1 gram of carbon nanotubes into a 200ml flask, add 100ml of ethanol, 50ml of water, 6.9ml of ammonia (28wt%) and CTAB (concentration of 5g per liter) in sequence and stir well. Then, 5 mL of methyl orthosilicate was added, reacted for 5 days, and centrifuged. After washing with a mixed solvent of ethanol and water, centrifuging, and drying at room temperature for 12 hours, a carbon nanotube@silica core-shell nanocomposite was obtained.

[0034] (2) Add the carbon nanotube@silica core-shell composite obtained in the previous step, 2 grams of nickel chloride, and ammonia water to adjust the pH to 12. Put the mixed solution into an autoclave, heat to 180°C, react for 48 hours, and cool to room temperature. Centrifuge, wash with methanol, ethanol, and water in sequence, and put it in a 100-degree drying oven. Get a carbon nanotube@silica@nickel silicate triple core-shell structure (such as image 3 shown). Specific area is 805m 2 g -1 , the nickel loading is 2...

Embodiment 3

[0037] (1) Put 0.5 g of carbon nanotubes into a 200 ml flask, add 100 ml of ethanol, 50 ml of water, 6.9 ml of ammonia (28 wt%) and CTAB (concentration of 5 g per liter) in sequence and stir well. Then, 1 mL of sodium silicate was added, reacted for 1 day, and centrifuged. After washing with a mixed solvent of ethanol and water, centrifuging, and drying at room temperature for 12 hours, a carbon nanotube@silica core-shell nanocomposite was obtained.

[0038] (2) Add ammonia water to the carbon nanotube@silica core-shell composite obtained in the previous step, 2 g of nickel acetylacetonate, and adjust the pH to 10. Put the mixed solution into an autoclave, heat to 150°C, react for 1 hour, and cool to room temperature. Centrifuge, wash with methanol, ethanol, and water in sequence, and put it in a 100-degree drying oven. Get a carbon nanotube@silica@nickel silicate triple core-shell structure (such as image 3 shown). Specific area is 505m 2 g -1 , the nickel loading is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com