Dragging steel belt

A technology for traction steel belt and steel belt, which is applied in the field of traction steel belt, can solve the problems of limiting the operation quality and promotion of steel belt elevators, easy wire breakage of steel belt, abnormal wear and other problems, and meets the requirements of breaking force and elongation , Reduce internal wear and avoid wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] This embodiment provides a traction steel strip with better breaking resistance and fatigue resistance, and the specific technical scheme is as follows:

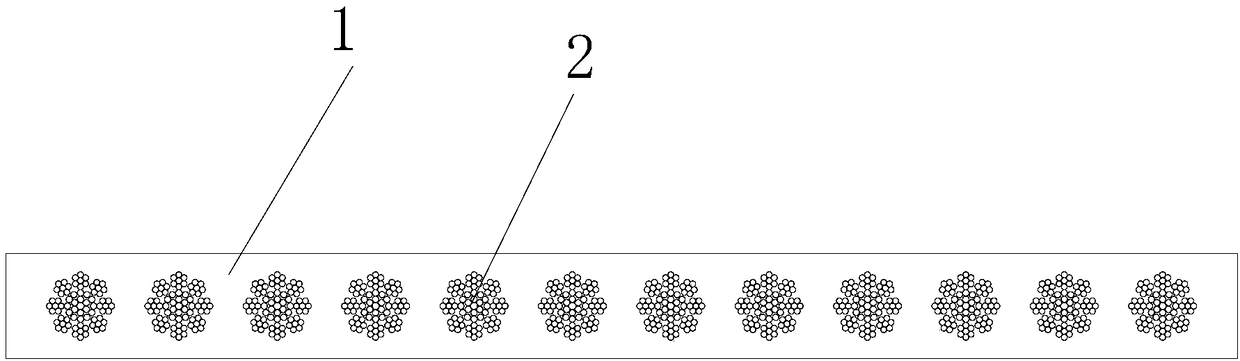

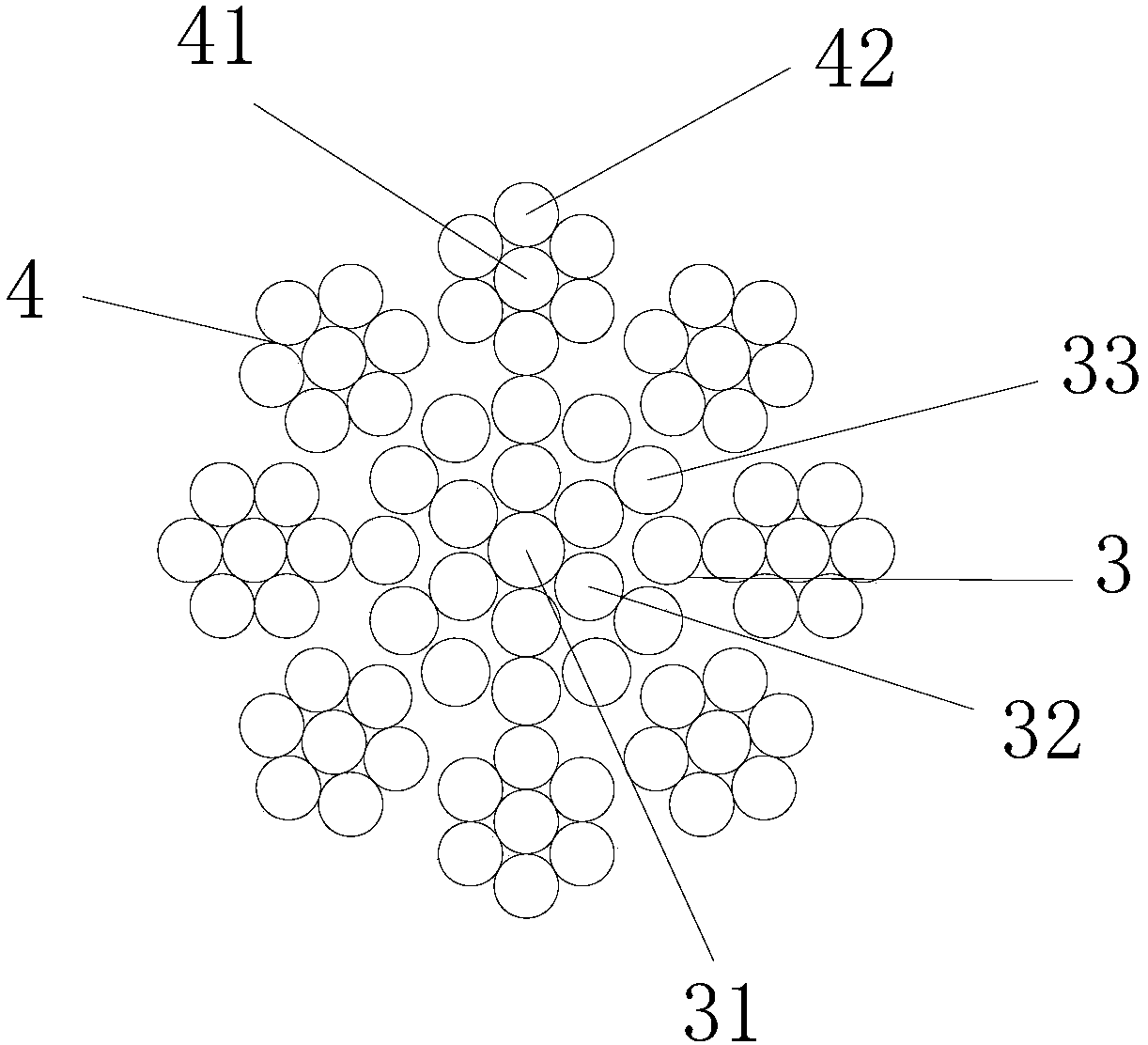

[0032] A traction steel belt, please refer to figure 1 , including a cladding layer 1 and a plurality of steel wire ropes 2 arranged at intervals in the cladding layer 1 .

[0033] The coating layer 1 is a flat structure, and the coating layer 1 is bonded to the surface of the steel wire rope 2. The coating layer 1 is made of an elastic material, and the elastic material is filled between a plurality of steel wire ropes 2 and wrapped around the steel wire rope 2, and is elastic. The material is immersed in the gap of the wire rope 2 body.

[0034] During the operation of the elevator, the steel wire rope 2 bends when passing the traction sheave. Due to the difference in curvature, there is a relative displacement between the steel wire ropes 2. The use of elastic material intervals can effectively avoid the wear of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com