Blue K type active dye, and preparation method thereof

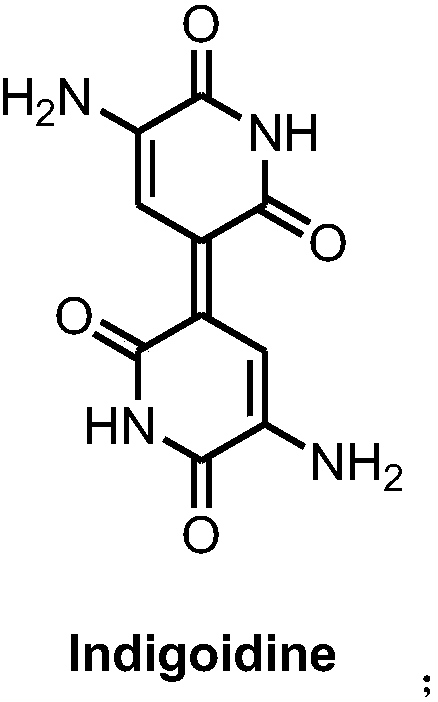

A reactive dye, K-type technology, applied in reactive dyes, dyeing methods, azo dyes, etc., can solve the problems of poor solubility of Indigoidine, poor oxidation resistance and heat resistance, difficult water medium dyeing, etc., to improve sun resistance Effects of light fastness, improvement of oxidation resistance and heat stability, and excellent color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

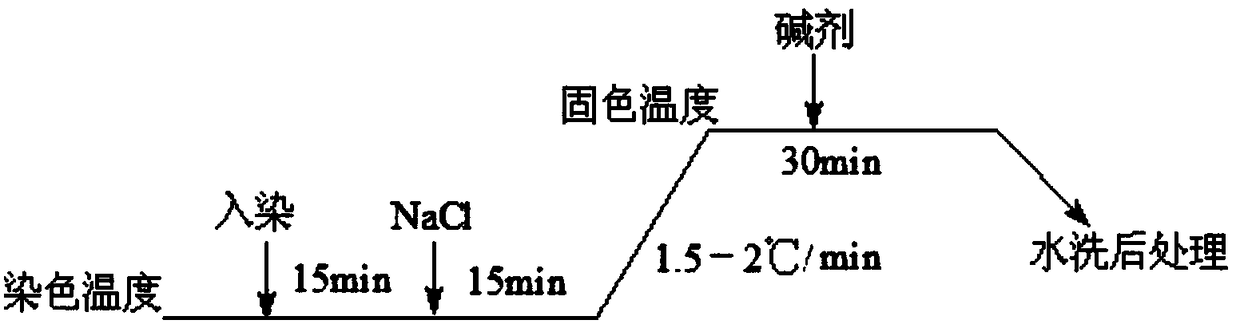

Method used

Image

Examples

Embodiment 1

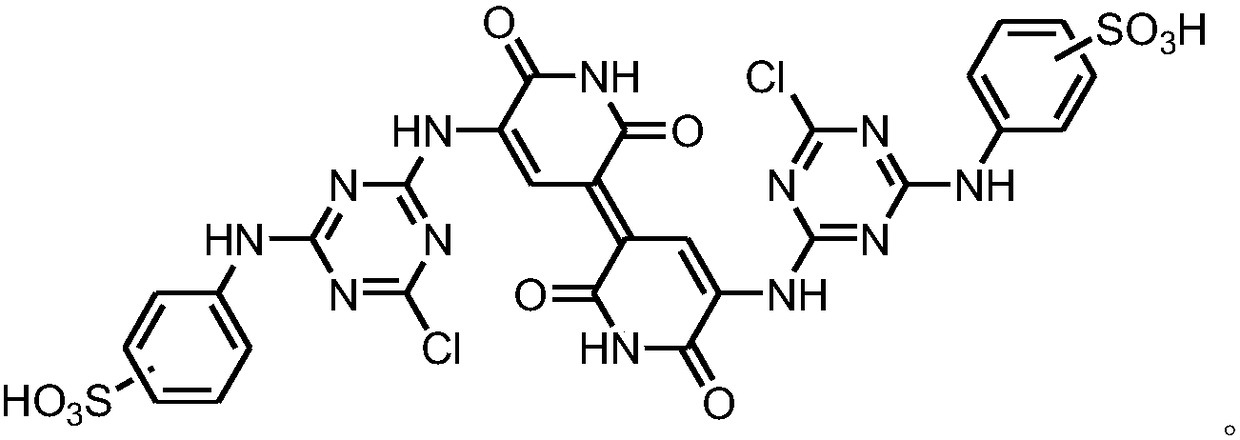

[0032] Embodiment 1, a kind of preparation method of blue K type reactive dye, carry out following steps successively:

[0033] 1), after grinding the Indigoidine dye finely with a mortar (can pass through a 300-mesh sieve), add 0.01mol of Indigoidine dye finely ground and 20mL water in a three-necked flask equipped with a stirrer and a thermometer, and stir to form a dispersion (dye Suspension), stand-by;

[0034] 2) Mix and dissolve 0.02mol of cyanuric chloride and p-aminobenzenesulfonic acid condensate with 20ml of water, then add to the dye dispersion, then add 0.01mol of potassium carbonate as an acid-binding agent, and react at 40°C for 6 hours;

[0035] The condensation product of described cyanuric chloride and p-aminobenzenesulfonic acid is

[0036] 3), after completion of the reaction, add 5% (mass %) HCl solution in the reaction solution to adjust the pH to 1, so that the blue product is separated out; after filtering, the filter cake is pickled (concentration is...

Embodiment 2

[0041] Embodiment 2, a kind of blue K type reactive dye and preparation method thereof, carry out following steps successively:

[0042] 1) After finely grinding the Indigoidine dye with a mortar, add 0.01 mol of finely ground Indigoidine dye and 20 mL of water into a three-neck flask equipped with a stirrer and a thermometer, and stir to form a dispersion liquid, which is ready for use;

[0043] 2) Mix and dissolve 0.02mol of cyanuric chloride and m-aminobenzenesulfonic acid condensate with 20ml of water, then add to the dye dispersion, then add 0.01mol of potassium carbonate as an acid-binding agent, and react at 60°C for 1 hour;

[0044] The condensation product of cyanuric chloride and m-aminobenzenesulfonic acid is

[0045]3), after completion of the reaction, add 5% HCl solution in the reaction solution to adjust the pH to 1, so that the blue product is separated out; The amount of time is 50ml, acid wash 3 times altogether) and dry (dry to constant weight at 50 ℃), o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com