Steel plate energy-consuming composite combined column capable of bearing primary and secondary force and installation method

A composite and combined column technology, applied in the direction of columns, pillars, pier columns, etc., can solve the problems of insufficient integrity of steel tube concrete composite columns, achieve the effects of improving self-recovery performance, reducing section size, and improving seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

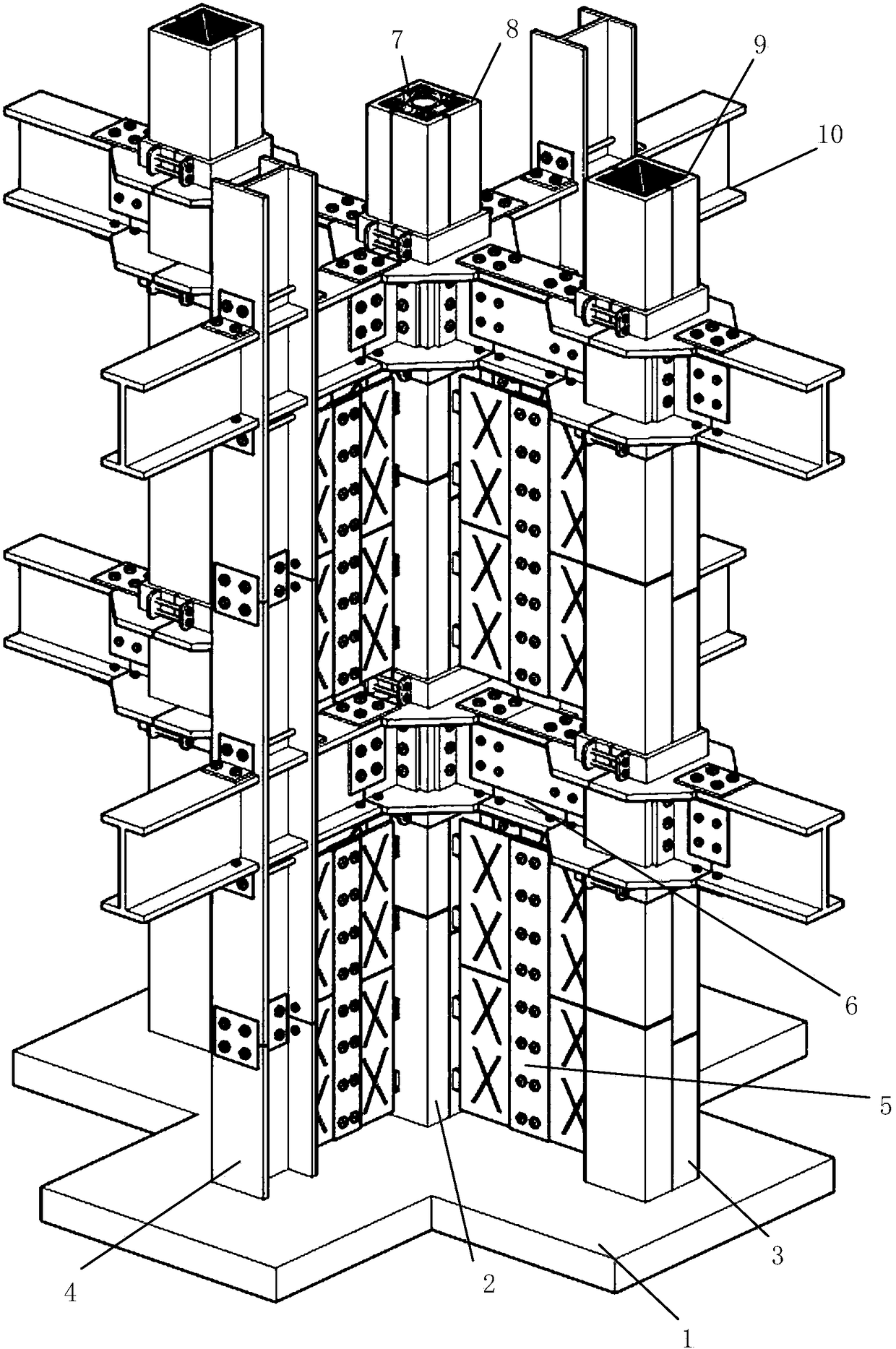

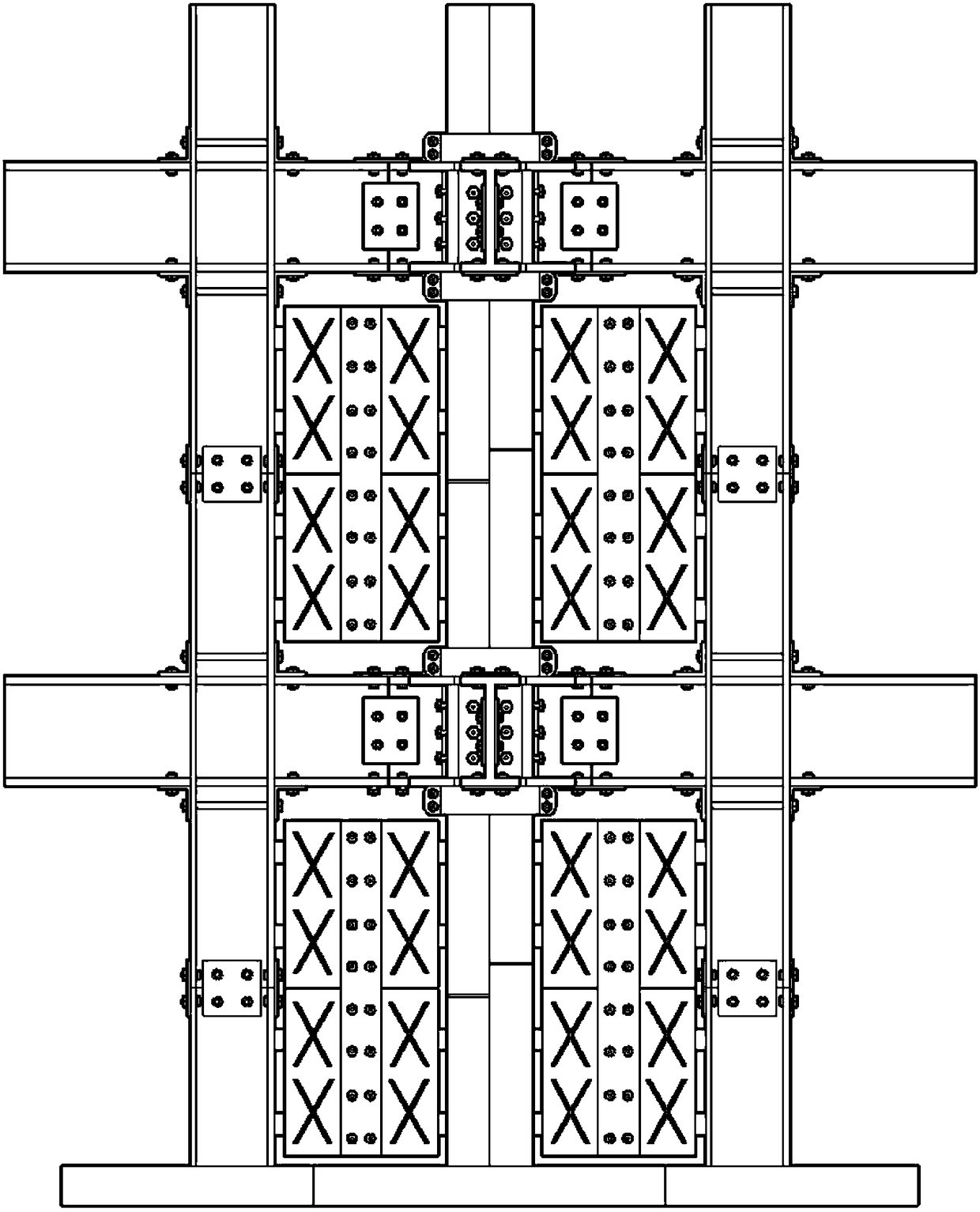

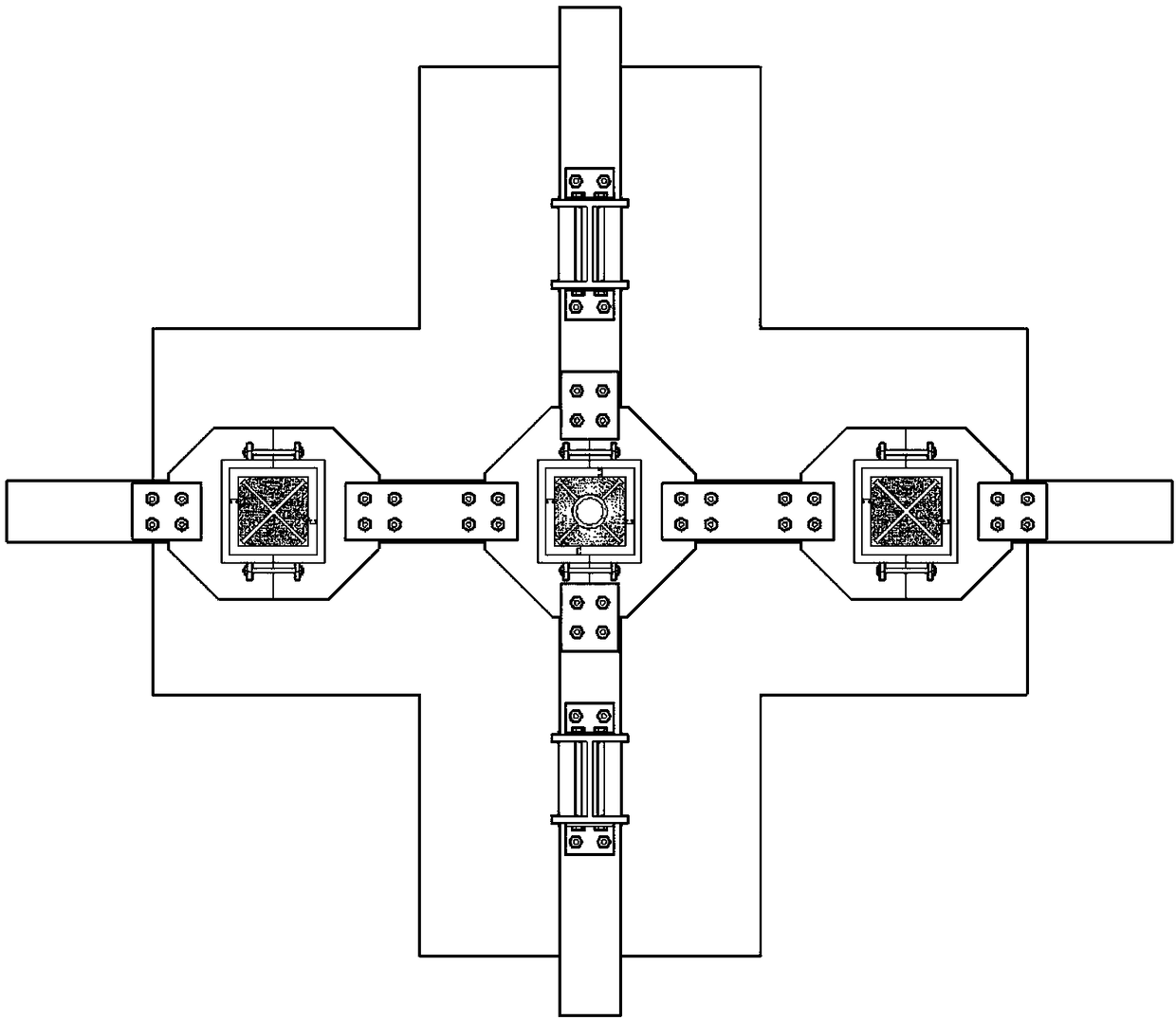

[0048] Such as Figure 1 to Figure 3 As shown, the structure of the present invention mainly includes an independent foundation 1, an A-type column 2, a B-type column 3, a C-type column 4, a hinged energy-consuming connecting member 5, and an interlayer connecting platform 6. Type A pillar 2, Type B pillar 3, and Type C pillar 4 are all vertically fixed on the independent foundation 1. The present invention adopts different columns in different directions, adopts type B columns 3 with strong shear resistance ability in the main force direction, and adopts type C columns 4 in the secondary force direction, which not only realizes the primary and secondary force, but also greatly The cross-sectional size of the composite column is reduced to a great extent, while sharing the vertical load of the structure, the structure layout is more flexible, and the combination of load bearing and space saving is realized, and the construction space and construction cost are fully saved.

[0049...

Embodiment 2

[0060] The square steel pipe of the present invention has various combinations. As shown in Figure 6(a) and Figure 6(b), whether it is A-shaped square steel pipe or B-shaped square steel pipe, it can be spliced in the form of composite members.

[0061] For example, in Figure 6(a), the square steel pipe is formed by successively splicing four square steel pipe composite members, and the shape of each square steel pipe composite member is an "L-shaped" structure. In order to avoid obstructing the fixing of other bolts on the central axis, the splicing position between the square steel tube composite members is not on the central axis of the square tube, but slightly to one side.

[0062] For example, in Figure 6(b), the square steel pipe is formed by successively splicing two square steel pipe composite members, and the shape of each square steel pipe composite member is a "gate-shaped" structure. In order to avoid obstructing the fixing of other bolts on the central axis, the sp...

Embodiment 3

[0064] Such as Figure 12 to Figure 13 As shown, there are also ways to form a side column combined column for the combination of Type A column 2, Type B column 3, and Type C column 4. To form a side column combined column, the present invention can still use the B-type column 3 with strong shear resistance in the main force direction and the C-type column 4 in the secondary force direction, which not only realizes the primary and secondary force, but also greatly This reduces the cross-sectional size of the composite column, makes the structure layout more flexible while sharing the vertical load of the structure, realizes the combination of load bearing and space saving, and fully saves building space and construction costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com