Gaseous medium dynamic caving and coal powder flowback mechanism simulation experimental device and method

A technology for simulating experimental devices and gas media, which is applied in mining devices, drilling equipment and methods, and earthwork drilling, etc. It can solve the problems of unclear process parameters in key links, and achieve easy adjustment, good safety performance, and convenient disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

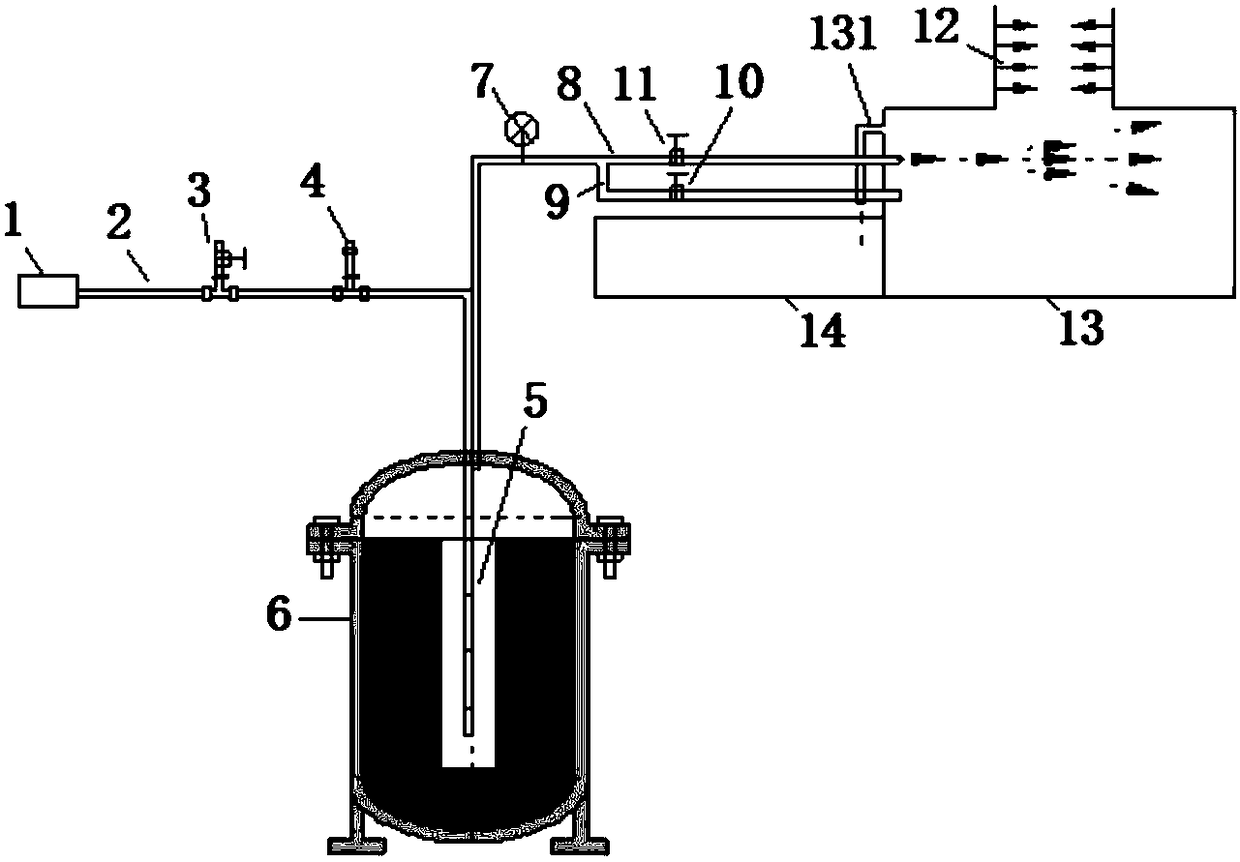

[0031] figure 1 It shows the simulated experiment device of the gas medium dynamic cavitation pulverized coal flowback mechanism of the present invention, which may include a multi-gas high-pressure gas injection sub-device, a main body device and a pulverized coal collection sub-device.

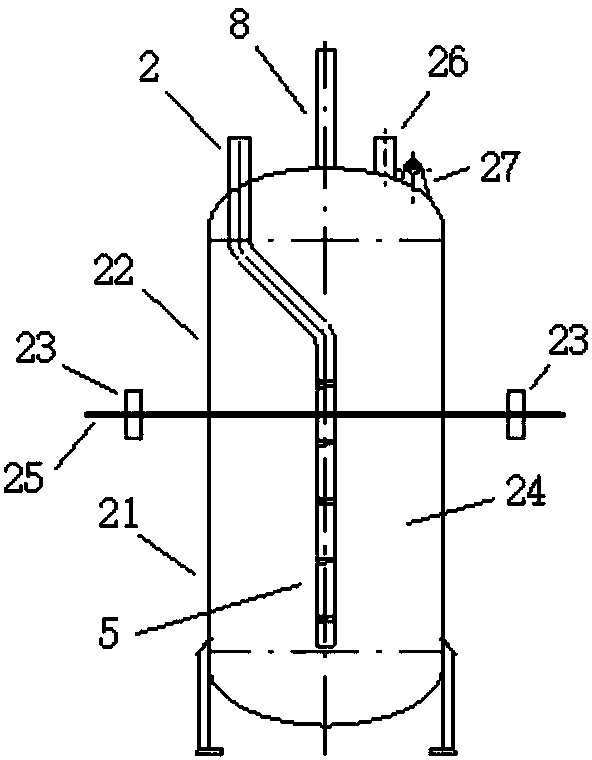

[0032] Wherein, the main device includes at least a simulated drill pipe 5 and a pressure chamber 6, the inner cavity 24 of the pressure chamber 6 is provided with a coal sample, and the simulated drill pipe 5 is arranged in the inner cavity 24 and extends into the coal sample. The gas high-pressure gas injection sub-device 1 is connected to the main device through the gas injection pipeline 2. The gas injection pipeline 2 extends into the pressure chamber 6 and is connected to the simulated drill pipe 5. The pulverized coal collection sub-device includes a dust collector 12, a pulverized coal Collection pool 13 and catchment pool 14, the pulverized coal collection pool 13 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com