Engine balance system

A technology of balancing system and engine, applied in the direction of machine/engine, mechanical equipment, inertia force compensation, etc., can solve the problems that affect the strength of the associated components, the operator's experience, the lack of elimination of vibration, the strong vibration of the engine, etc., and achieve ingenious structural design. , The effect of improving the service life and reducing the external size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

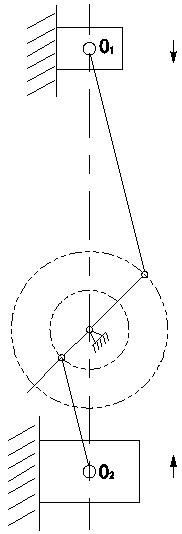

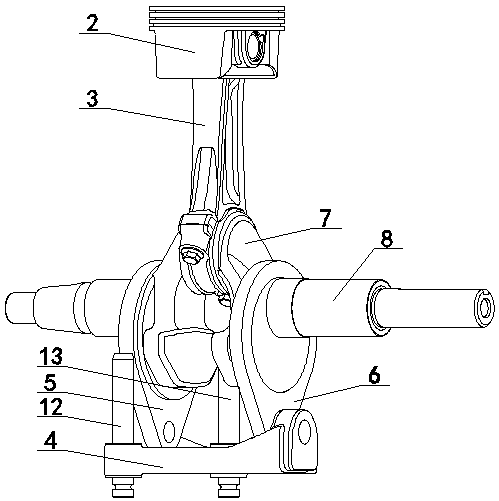

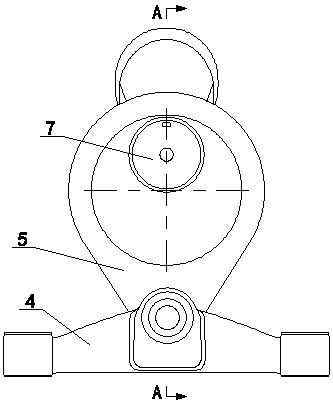

[0037] Embodiment 1: as figure 1 , 2 . As shown in 3, an engine balancing system includes an engine body member, which is characterized in that: at least two crank slider mechanisms are arranged in the engine body member, and one of the crank slider mechanisms is connected to the other crank slider mechanism. The block mechanisms are arranged oppositely; the velocity and acceleration of the slider movement in one of the slider-crank mechanisms are similar to the velocity and acceleration characteristics of the slider movement in the other slider-crank mechanism, and the ratio is approximately constant.

[0038] Wherein, in order to make the vibration elimination effect better, the crank-slider mechanism includes a connecting rod and a crankshaft 8 with a crank 7, and the length of the connecting rod and the crank eccentricity of one of the crank-slider mechanisms are L respectively. 1 and e 1 , the connecting rod length and crank eccentricity of the other slider-crank mechan...

Embodiment 2

[0060] Embodiment 2: as Figure 7 As shown, when the engine type in the engine balance system is a two-cylinder in-line engine, the balance system is composed of a first slider crank mechanism, a second slider crank mechanism and a third slider crank mechanism. The first slider-crank mechanism includes the first cylinder crank 18 driven by the first cylinder piston 16, the first cylinder connecting rod 17 and the movement of the first cylinder piston 16. The second slider-crank mechanism includes the first cylinder crank 18 driven by the first cylinder piston 16. Second cylinder piston 19, second cylinder connecting rod 20 and the second cylinder crank 21 that drives the movement of second cylinder piston 19, the third crank slider mechanism includes counterweight 22, secondary connecting rod 23 and driving counterweight 22 movement third crank. Wherein the first slider-crank mechanism and the second slider-crank mechanism are arranged opposite to the third slider-crank mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com