Flat-convex engaged pure rolling mechanism for inside engaging transmission of parallel shafts

A gear mechanism and internal meshing technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the uncertain value of the coincidence degree of the transmission pair, the strict design of the coincidence degree cannot be realized, and it is not conducive to the uniform distribution of loads And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

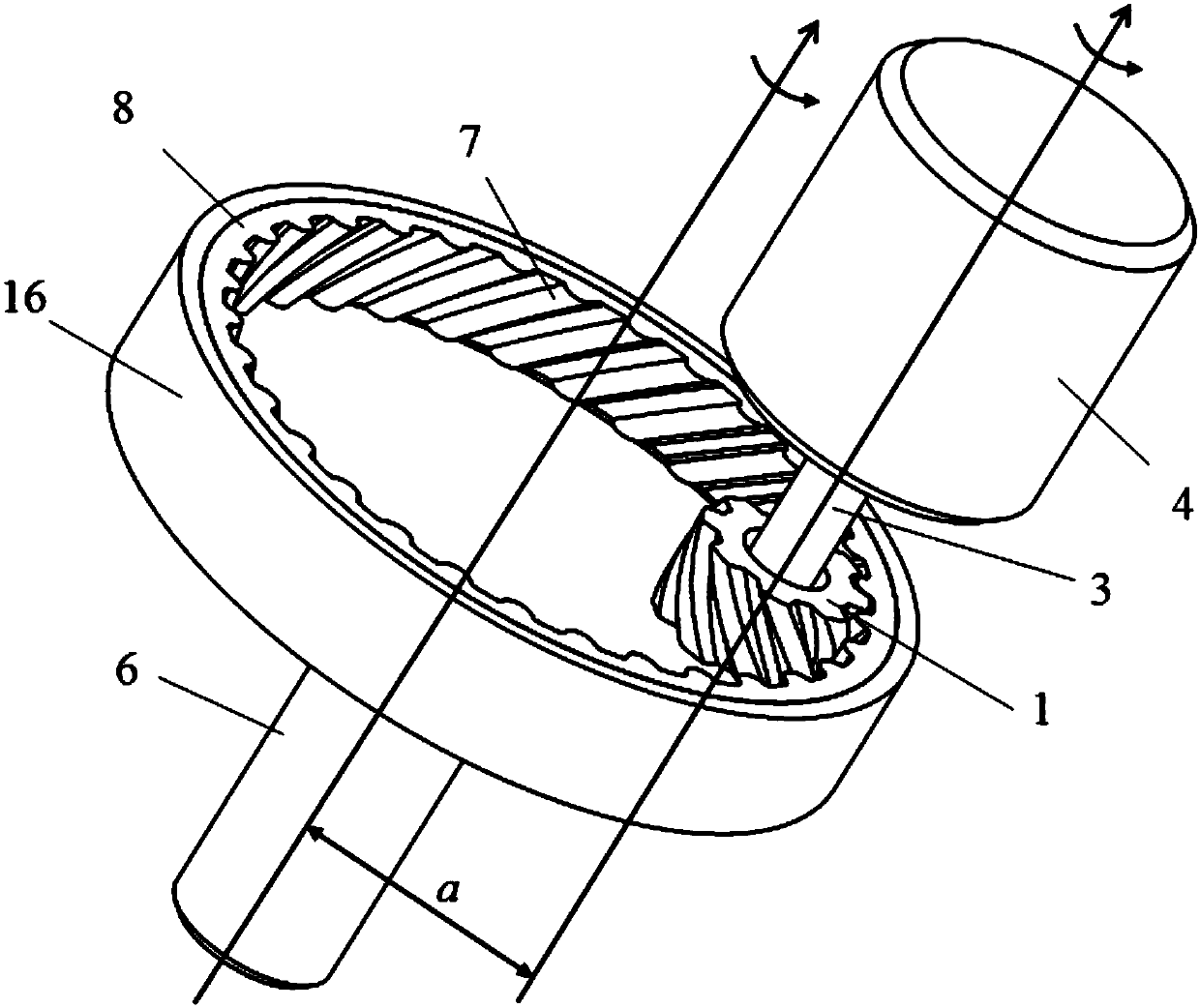

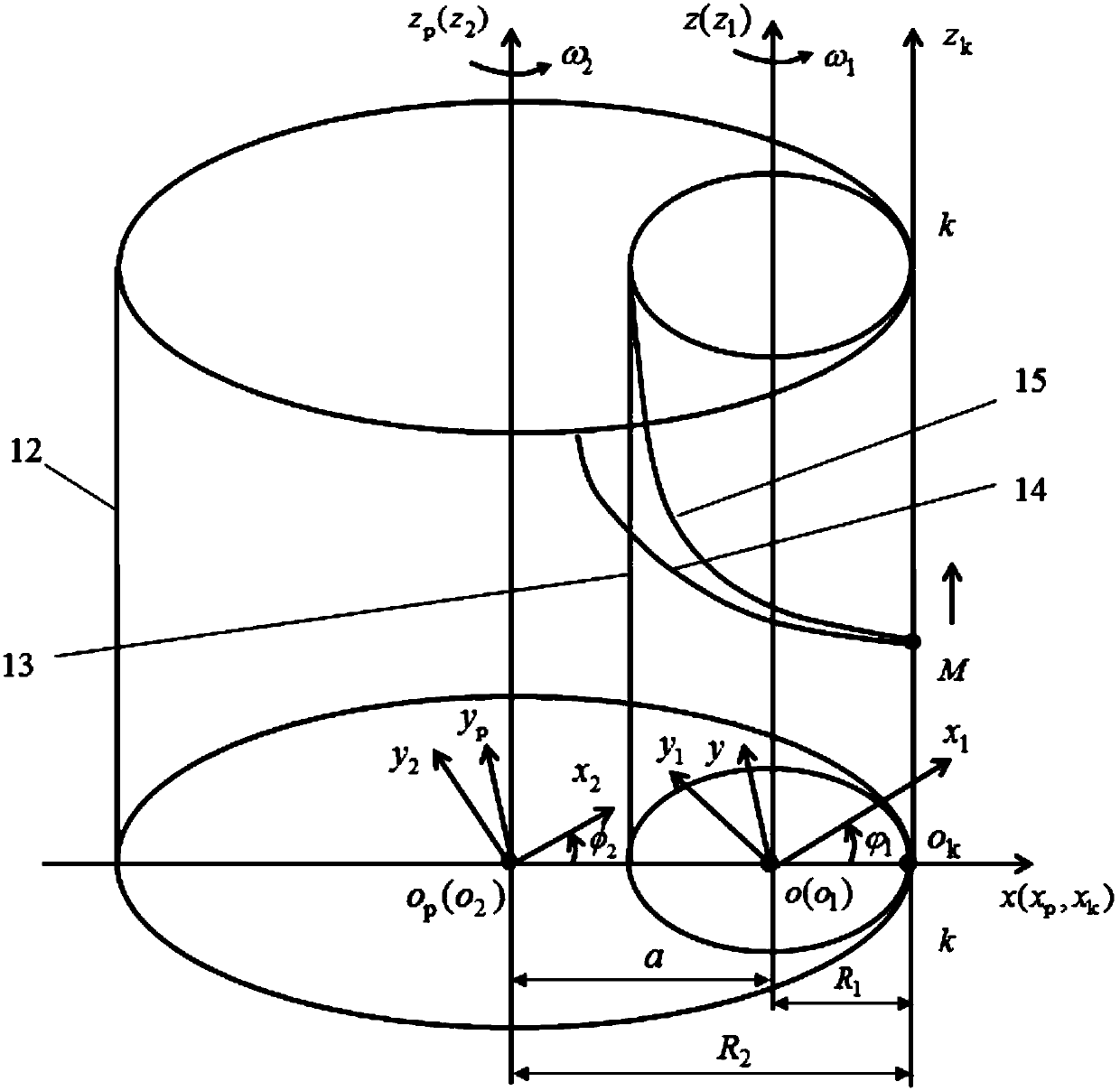

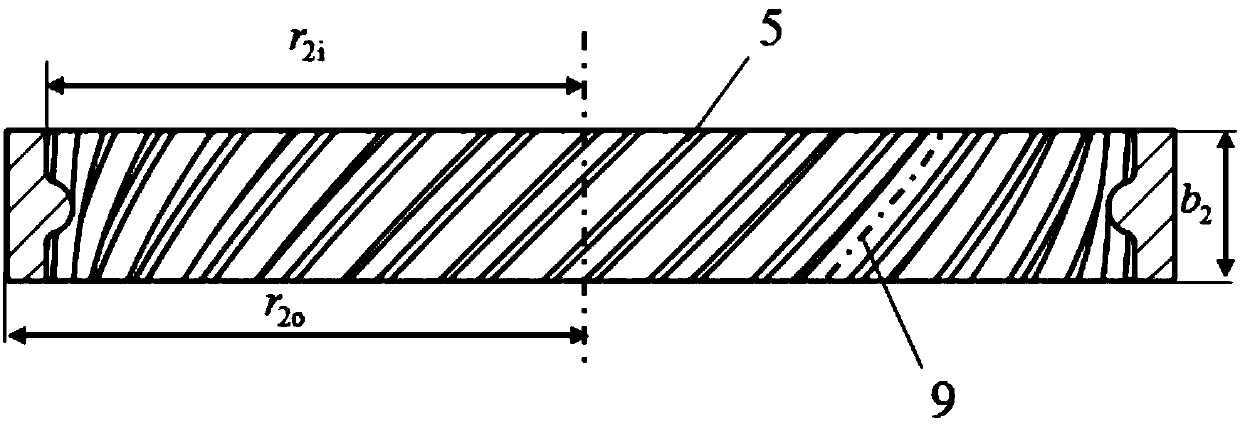

[0097] The present invention provides a flat-convex meshing pure rolling gear mechanism for internal meshing transmission of parallel shafts, which is applied to transmissions with a transmission ratio of 4 between parallel shafts, and their coincidence degree is designed to be ε=2. Its structure is as figure 1 As shown, it includes a small wheel 1 and a large ring gear 8. The small wheel 1 and the large ring gear 8 form a pair of transmission pairs. The small wheel 1 is connected to the input shaft 3, and the small wheel 1 is connected to the input shaft 3 through the small wheel center hole 10, and There is a small wheel center hole chamfer 11 on the small wheel center hole 10, and the large ring gear 8 is connected to the output shaft 6 through the connecting sleeve 16, that is, the large ring gear 8 is connected with the driven load through the output shaft 6; the small wheel 1 and the axes of the large ring gear 8 are parallel to each other. figure 2 It is a schematic d...

Embodiment 2

[0181] The flat-convex meshing pure rolling gear mechanism of the parallel shaft internal meshing transmission of the present invention is applied to the speed-up transmission of the parallel shaft. Such as Figure 7 As shown, the large ring gear 8 is used to connect the input shaft 3 through the connecting sleeve 16, and the small wheel 1 is connected to the output shaft 6 through the small wheel center hole 10, that is, the small wheel 1 is connected to the driven load through the output shaft 6; the small wheel 1 and the The axes of the large ring gear 8 are parallel. In this embodiment, there are 30 spiral arc teeth 7 on the large ring gear 8, and 6 spiral trapezoidal grooves 2 on the small wheel 1, and the design coincidence degree ε=1.5. When the input shaft 3 drives the large ring gear 8 to rotate, because when the large ring gear 8 and the small wheel 1 are installed, the spiral circular arc tooth 7 on the large ring gear 8 is in the meshing state with a spiral trapez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com