Self-overlapping low-environment-temperature air source heat pump system

An air-source heat pump and low-temperature system technology, which is applied in lighting and heating equipment, irreversible cycle compressors, refrigeration components, etc., can solve problems such as unusable, reduce the number of components, and improve energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

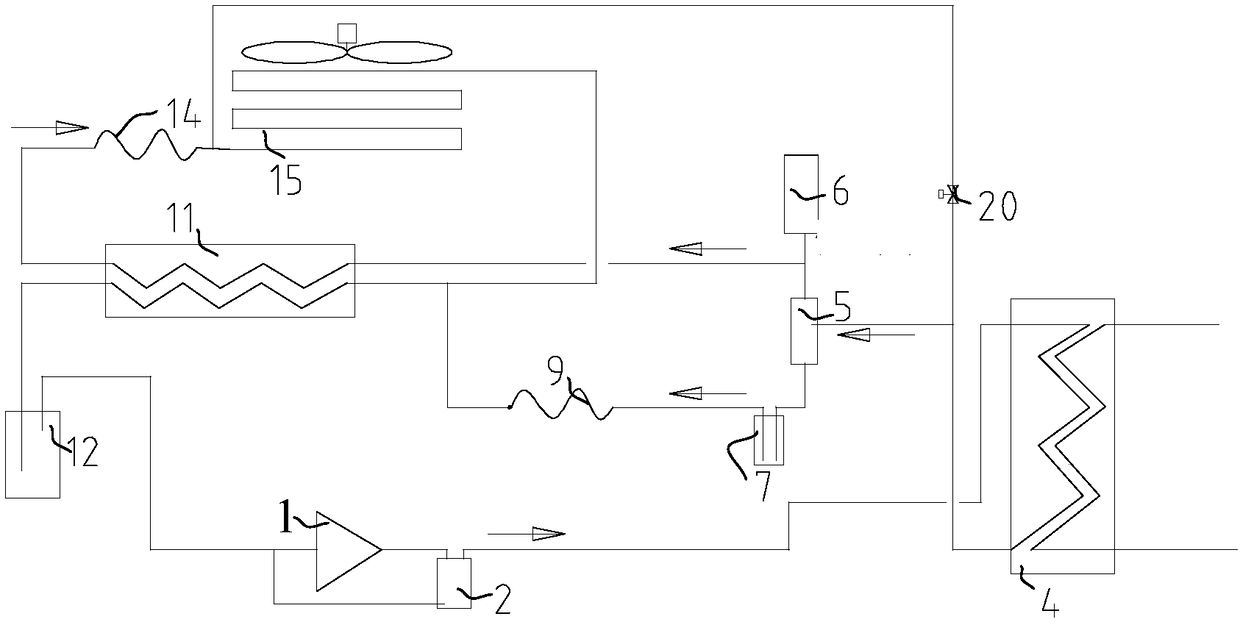

[0041] Such as figure 1 As shown, a self-cascade low ambient temperature air source heat pump system includes a refrigerant compression system, a heating device, a low temperature system, a high temperature system, and an intermediate heat exchanger 11, a refrigerant compression system, a heating device, and a high temperature system It is connected to the intermediate heat exchanger 11 in turn to form a high-temperature refrigerant cycle system. The low-temperature refrigerant in the low-temperature system undergoes primary heat exchange through the intermediate heat exchanger 11, and then exchanges secondary heat with the air-cooled heat exchanger 15 , And merge the low-temperature refrigerant after the secondary heat exchange into the high-temperature refrigerant that has not passed through the intermediate heat exchanger 11 for a mixing cycle.

[0042] The beneficial effects of this embodiment are: the refrigerant compression system, the heating device, the high-temperature sy...

Embodiment 2

[0044] Such as figure 1 As shown, a self-cascade low ambient temperature air source heat pump system includes a refrigerant compression system, a heating device, a low temperature system, a high temperature system, and an intermediate heat exchanger 11, a refrigerant compression system, a heating device, and a high temperature system It is connected to the intermediate heat exchanger 11 in turn to form a high-temperature refrigerant cycle system. The low-temperature refrigerant in the low-temperature system undergoes primary heat exchange through the intermediate heat exchanger 11, and then exchanges secondary heat with the air-cooled heat exchanger 15 , And merge the low-temperature refrigerant after the secondary heat exchange into the high-temperature refrigerant that has not passed through the intermediate heat exchanger 11 for a mixing cycle.

[0045] It is understandable that the refrigerant compression system, the heating device, the high temperature system, and the interme...

Embodiment 3

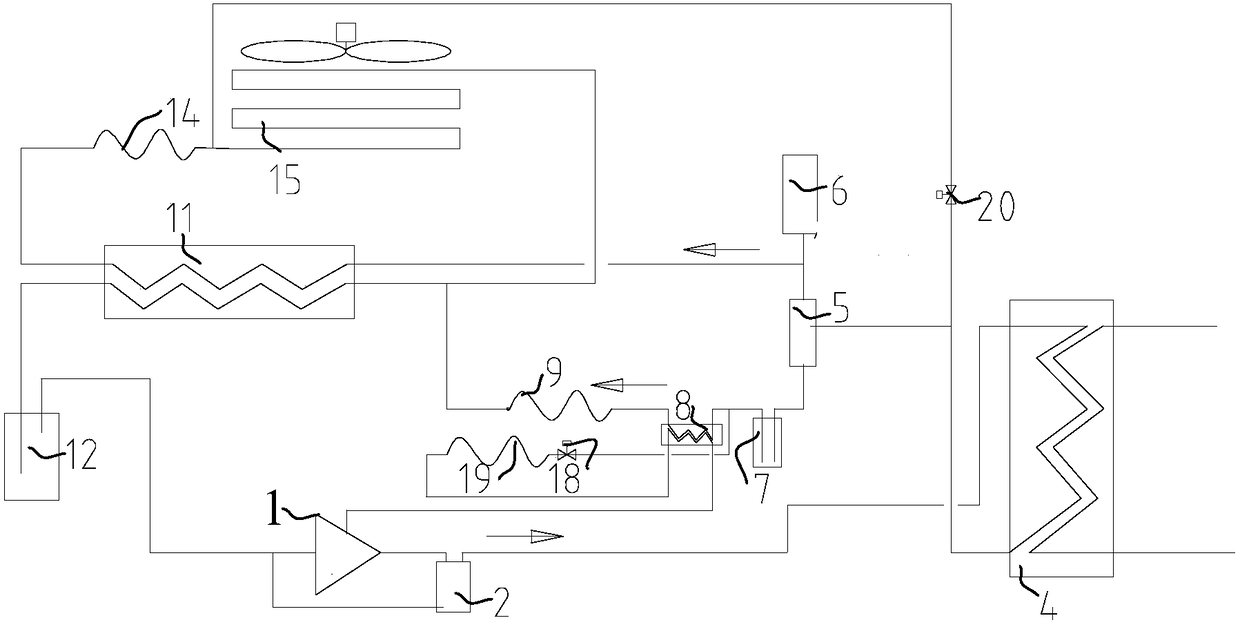

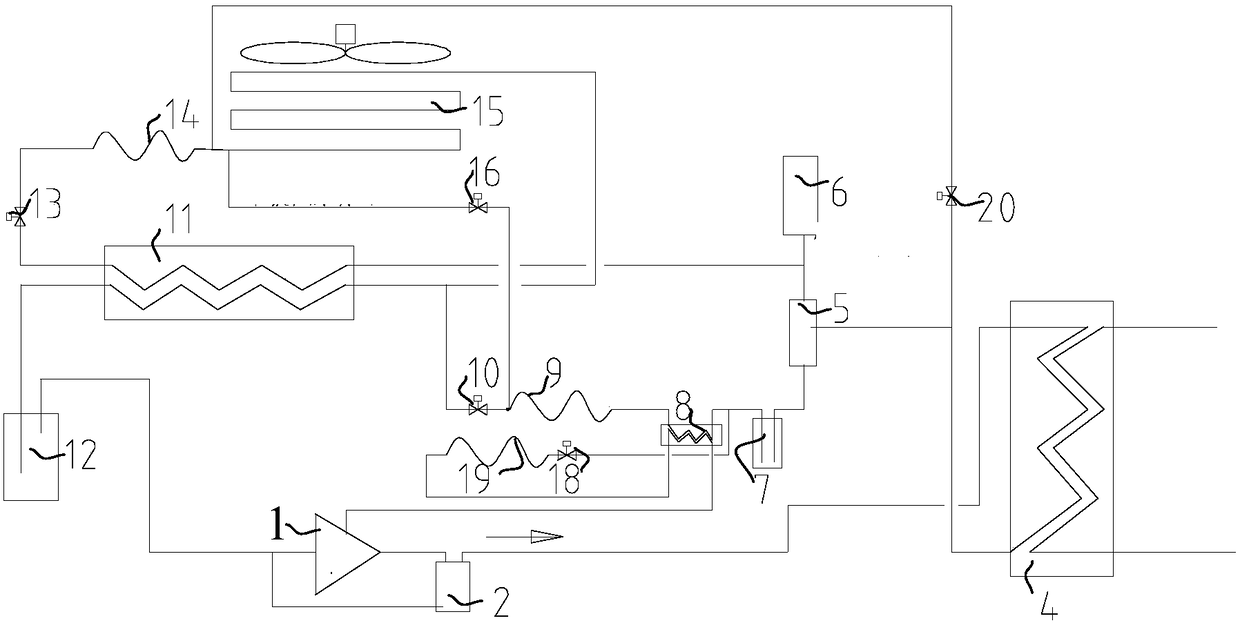

[0062] Such as figure 2 As shown, this embodiment adds an economizer on the basis of Embodiment 2. The economizer is arranged on the pipeline connecting the main expansion valve 9 and the two-way accumulator 7. The economizer includes an economizer body 8 and an economizer expansion valve 19. , The high-temperature refrigerant separated by the first gas-liquid separator 5 is split after passing through the two-way accumulator 7: part of the high-temperature refrigerant enters the economizer body 8 for heat exchange, and then enters the main expansion valve 9 after heat exchange; another part of the high-temperature refrigerant After entering the economizer expansion valve 19, it enters the economizer body 8 for heat exchange and then enters the compressor 1, and an economizer solenoid valve 18 is installed at the entrance of the economizer expansion valve 19.

[0063] The working process of this embodiment is: when the economizer solenoid valve 18 is closed, the working process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com