Detection method for sub-surface damage layer thickness of silicate glass

A silicate glass, subsurface damage technology, applied in measuring devices, instruments, etc., can solve problems such as cracks and residual stress not being amplified, micron-scale crack shape, position detection difficulties, and imperfect response mechanism research. The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

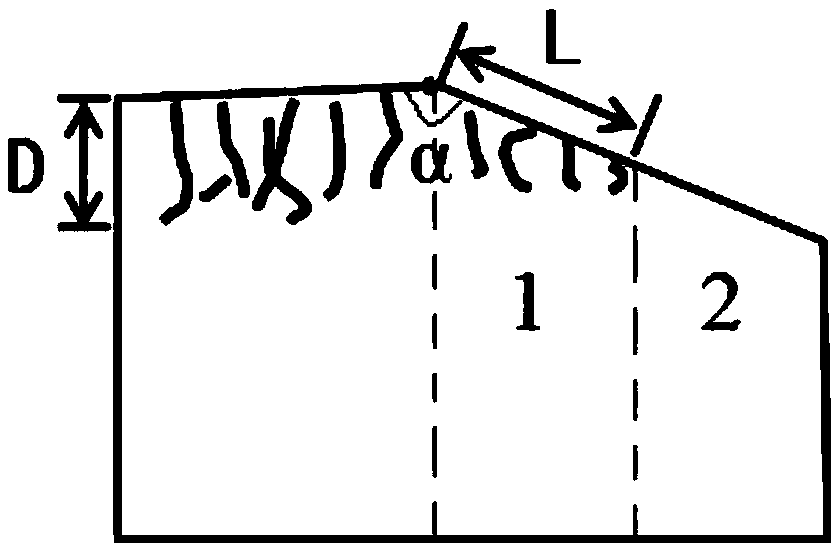

[0033] A method for detecting the thickness of a silicate glass subsurface damage layer proposed by an embodiment of the present invention, which includes:

[0034] Use a cutting machine to cut a bevel on the silicate glass sample, the inclination angle α is 175°, rinse the cutting oil and cutting particles on the surface of the sample with deionized water, and then place the sample in absolute ethanol for ultrasonic cleaning for 15 minutes. Ultrasonic frequency 40Hz;

[0035] Use a polishing machine to polish the inclined surface. The polishing medium is a fluid polishing liquid, and the polishing liquid is CeO 2 Suspension, suspension concentration is 200g / L, CeO2 The particle size is not more than 1 μm, and the polishing removal amount is 100 μm. Rinse the polishing liquid and polishing particles on the surface of the sample with deionized water, and then place the sample in absolute ethanol for ultrasonic cleaning. The ultrasonic frequency is 40 Hz and the cleaning time is...

Embodiment 2

[0039] A method for detecting the thickness of a silicate glass subsurface damage layer proposed by an embodiment of the present invention, which includes:

[0040] Use a cutting machine to cut a bevel on the silicate glass sample, the inclination angle α is 165°, rinse the cutting oil and cutting particles on the surface of the sample with deionized water, and then place the sample in absolute ethanol for ultrasonic cleaning for 10 minutes. Ultrasonic frequency 40Hz;

[0041] Use a polishing machine to polish the inclined surface. The polishing medium is a fluid polishing liquid, and the polishing liquid is Fe 2 o 3 Suspension, suspension concentration is 400g / L, Fe 2 o 3 The particle size is not more than 1 μm, and the polishing removal amount is 80 μm. Rinse the polishing solution and polishing particles on the surface of the sample with deionized water, and then place the sample in absolute ethanol for ultrasonic cleaning. The ultrasonic frequency is 80 Hz and the clean...

Embodiment 3

[0045] A method for detecting the thickness of a silicate glass subsurface damage layer proposed by an embodiment of the present invention, which includes:

[0046] Use a cutting machine to cut a bevel on the silicate glass sample, the inclination angle α is 160°, rinse the cutting oil and cutting particles on the surface of the sample with deionized water, and then place the sample in absolute ethanol for ultrasonic cleaning for 15 minutes. Ultrasonic frequency 80Hz;

[0047] Use a polishing machine to polish the inclined surface. The polishing medium is a fluid polishing liquid, and the polishing liquid is Fe 2 o 3 Suspension, suspension concentration is 300g / L, Fe 2 o 3 The particle size is not more than 1 μm, and the polishing removal amount is 80 μm. Rinse the polishing solution and polishing particles on the surface of the sample with deionized water, and then place the sample in absolute ethanol for ultrasonic cleaning. The ultrasonic frequency is 80 Hz and the clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com