Three-dimensional coordinate reference field indoor space measuring, positioning and scanning light face calibration method

A three-dimensional coordinate, indoor space technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of system error, affecting the system measurement accuracy, affecting the coordinate measurement accuracy of multi-transmitting station networking, etc., to achieve the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

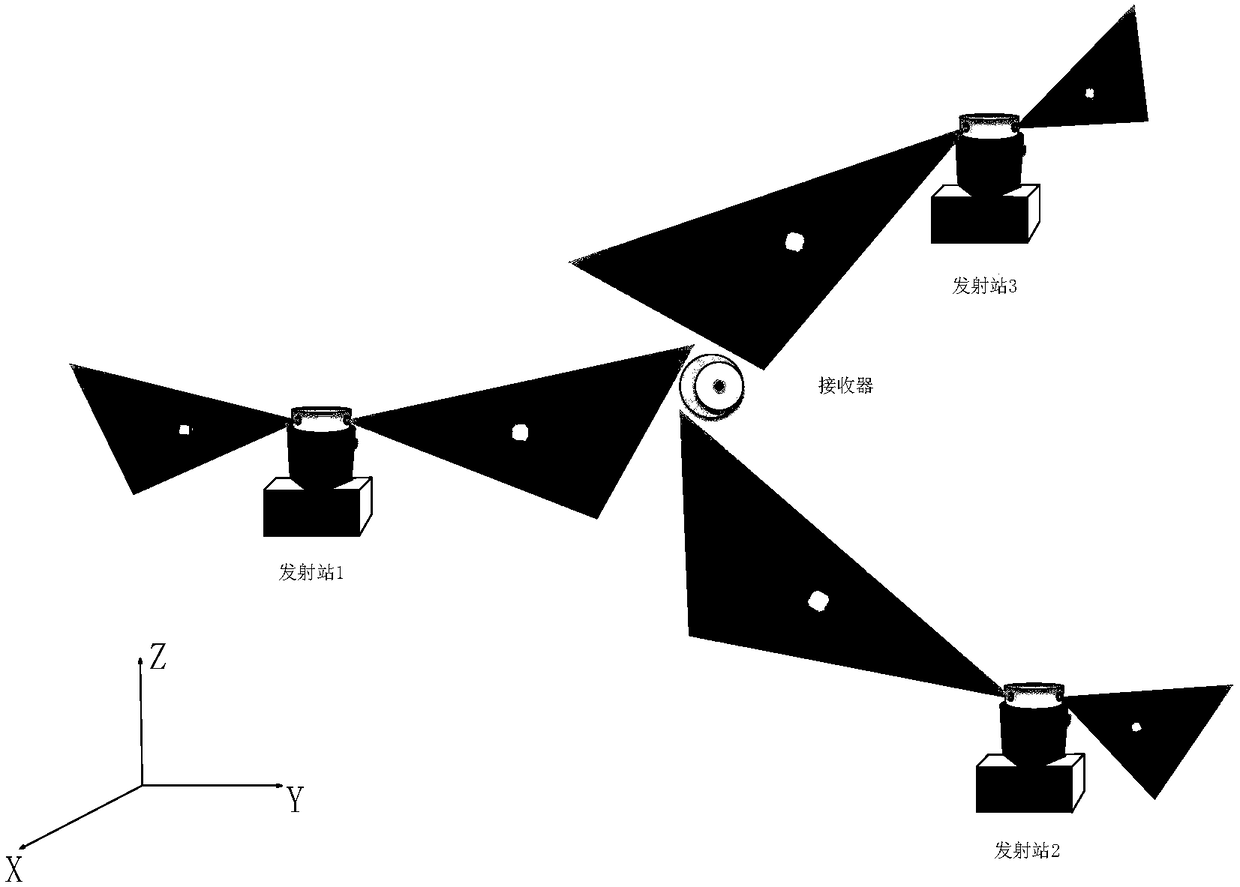

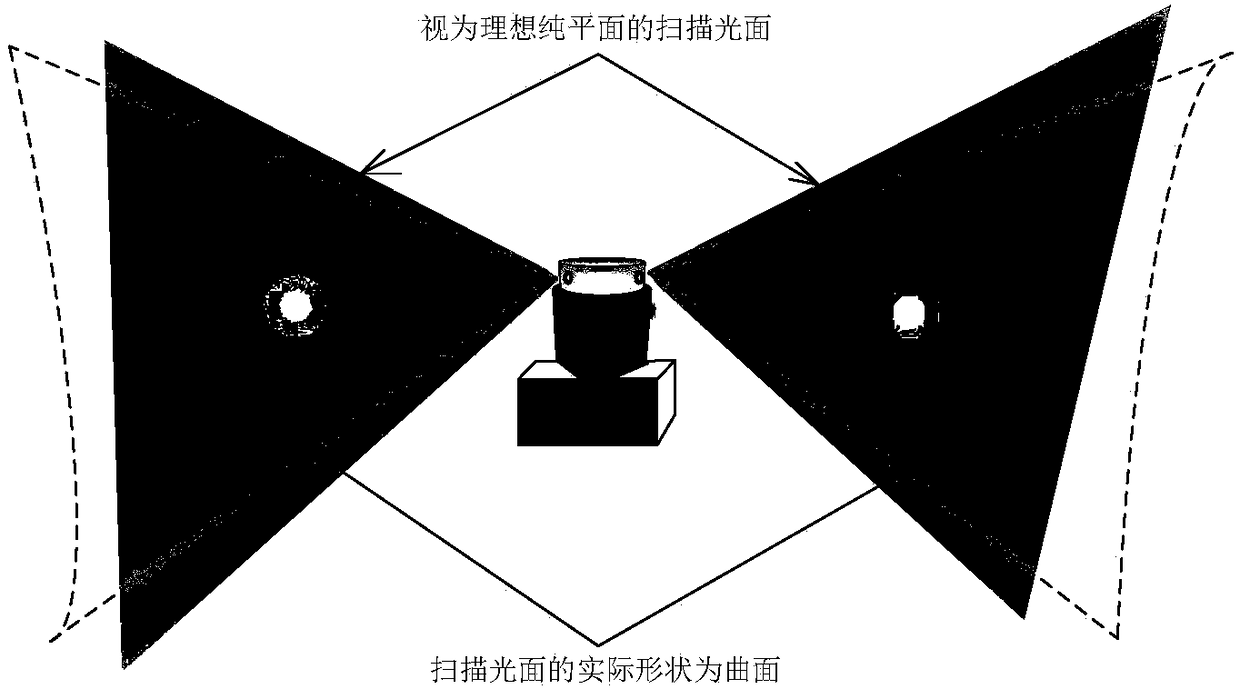

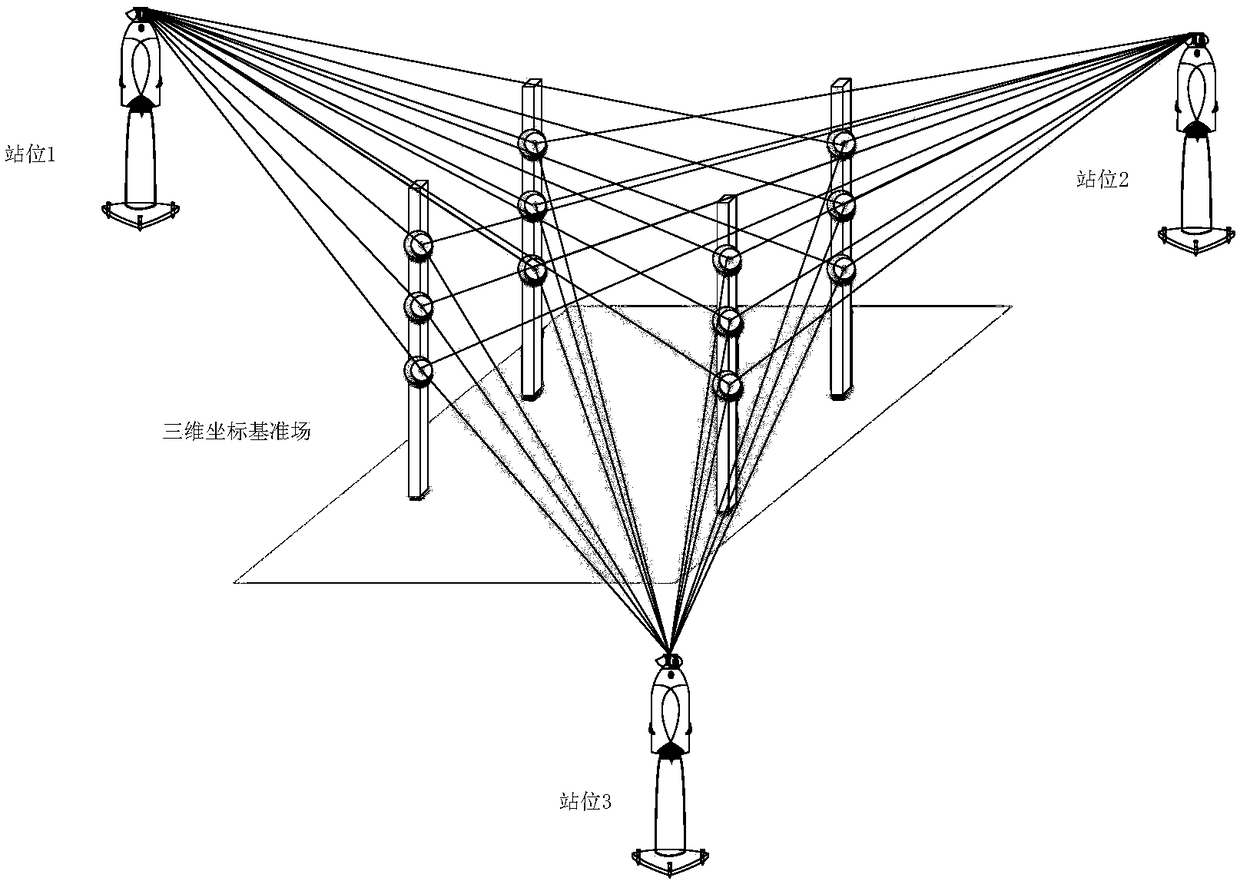

[0048] In view of the actual situation of wMPS, in order to obtain the structural parameters of the scanning optical surface that fit its actual shape, the present invention makes full use of the high precision of laser tracker interferometric distance measurement, and provides a method for calibrating the scanning optical surface of wMPS based on the three-dimensional coordinate reference field to calibrate the scanning surface. After the control points are laid out, the laser tracker is used to measure the error characteristics, the redundant length measurement constraints are established, and the three-dimensional coordinate reference field is constructed by using the method of weighted optimization of the angle measurement error, which is used as the reference for the calibration of the geometric model parameters of the WMPS scanning smooth surface. The method is to establish the actual and exact geometric shape of the scanning surface, and improve the measurement performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com