Normal contact force testing method of spherical particle system under impact action

A technology of spherical particles and impact action, applied in the direction of force/torque/work measuring instruments, measuring devices, measuring force components, etc., can solve the problems of particle material breaking, experiment failure, and no quantitative control of impact load, etc., to achieve accuracy High, simple operation method, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

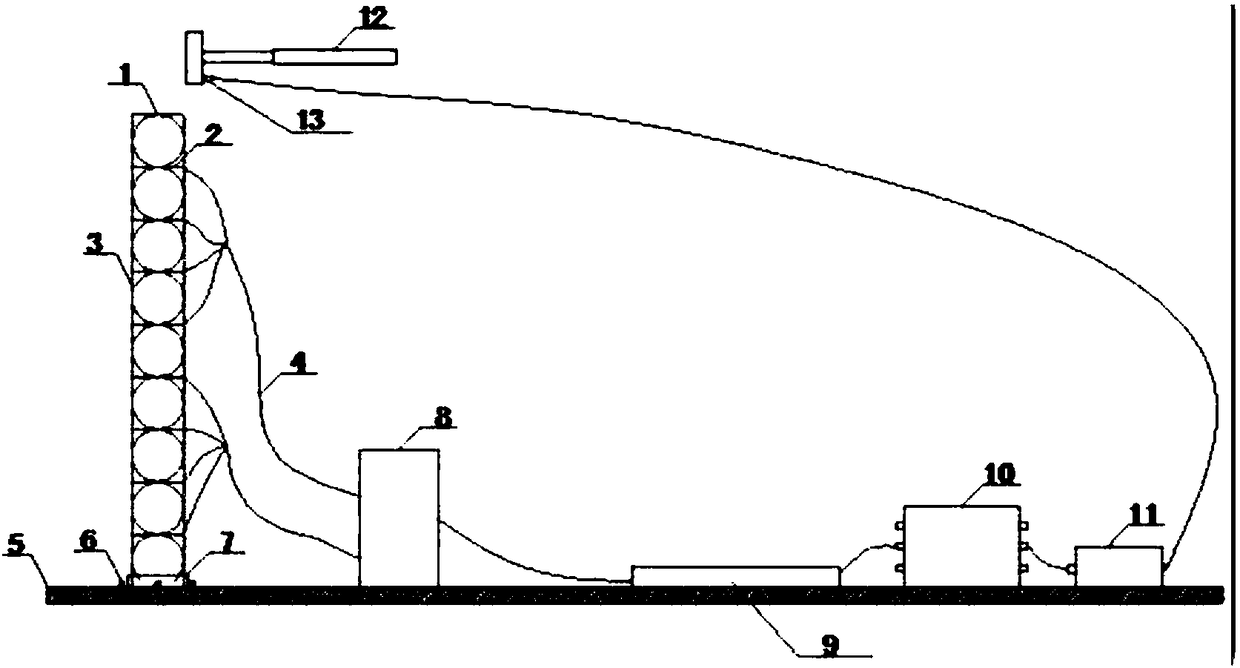

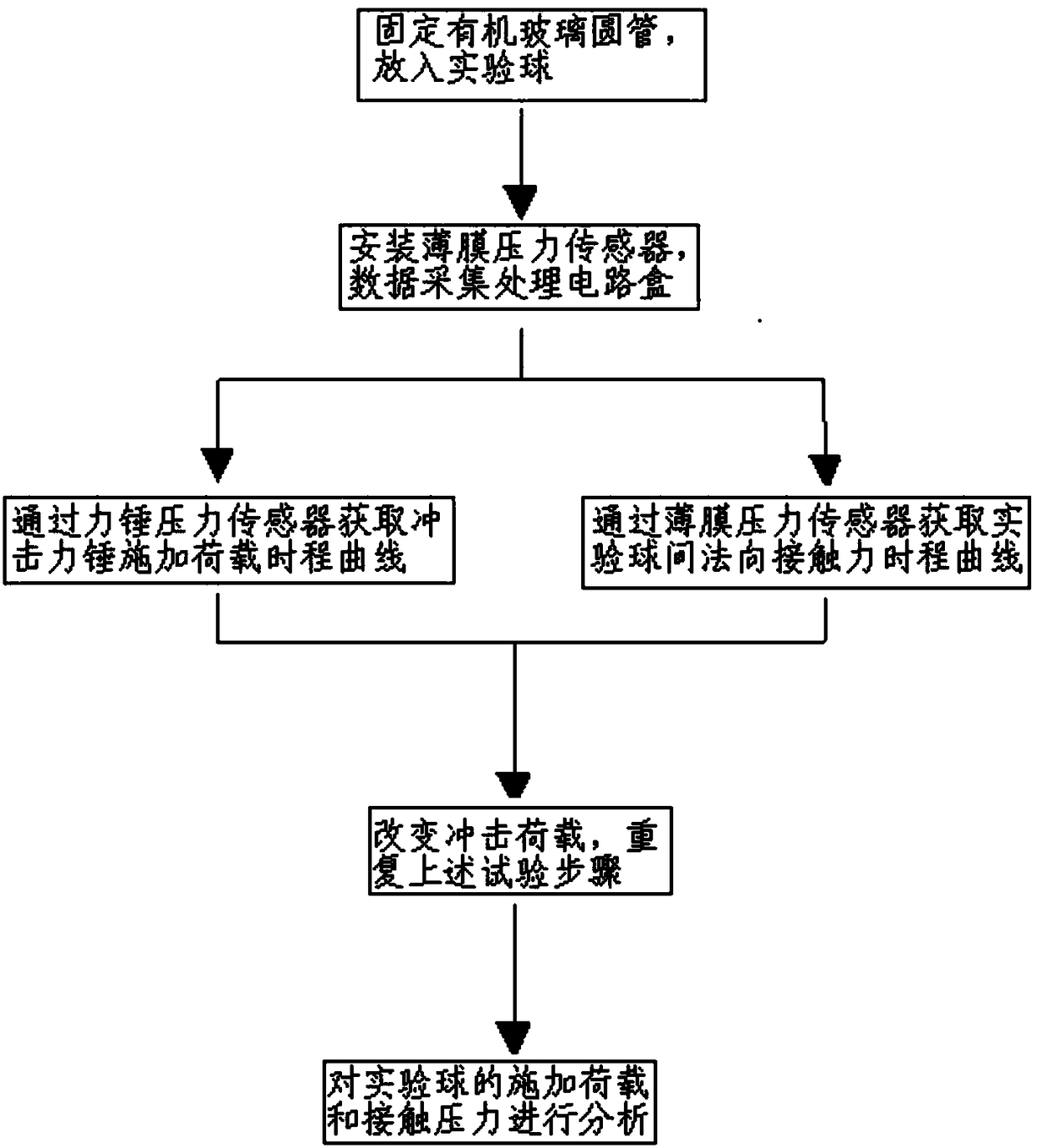

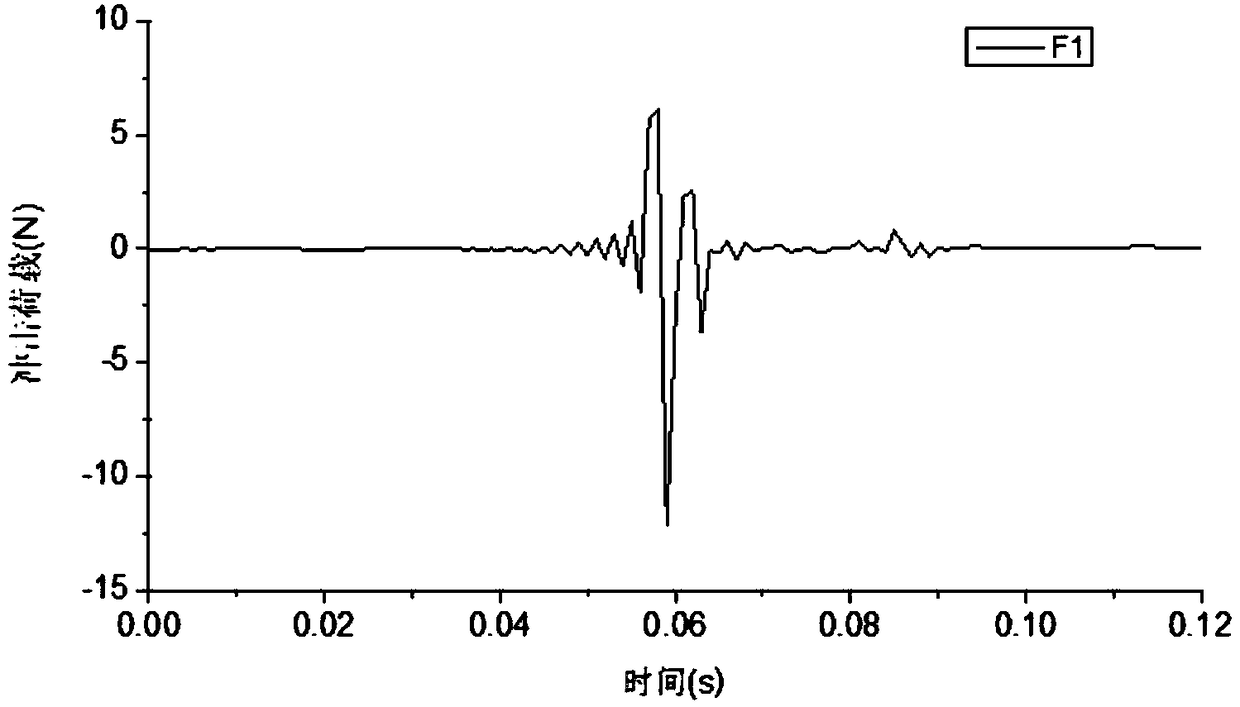

[0045] Embodiment 1, the device that the present application adopts is: comprise impact force hammer 12, force hammer pressure sensor 13, signal converter 11, dynamic signal test analysis device 10, experiment ball 1, film pressure sensor 2, plexiglass circular tube 3, Wire 4, support plate 5, connecting screw 6, fixing sleeve 7, data acquisition and processing circuit box 8 and computer 9.

[0046] The fixing sleeve is installed on the support plate through the connecting screw, one end of the plexiglass tube is installed on the support plate through the fixing sleeve, and the experimental ball is placed in the plexiglass tube. On a straight line, the thin-film pressure sensor is placed between the experimental ball and the experimental ball. The thin-film pressure sensor is connected to the data acquisition and processing circuit box through a wire, and the data acquisition and processing circuit box is connected to the computer; the impact hammer is used to apply the impact ...

Embodiment 2

[0059] The pressurizing mechanism includes a gas supply bottle, a gas storage chamber, a fixed bracket, a loading plate and a piston; the gas supply bottle, the gas storage chamber and the loading plate are connected in sequence through a gas pipeline; the gas supply bottle is provided with a barometer and a gas valve switch; The gas supply bottle is connected to the gas storage chamber through the gas transmission pipe, and the gas storage chamber is equipped with a control switch and a pressure gauge; the gas storage chamber acts on the loading plate through the gas transmission pipe, and one end of the fixed bracket is sealed with a seamless steel pipe; the loading plate is connected On the other end of the fixed bracket; the piston is located below the loading plate and at the upper end of the plexiglass tube; the side of the loading plate in contact with the piston is provided with an impact sensor; the outer diameter of the piston is consistent with the inner diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com