Multi-task parallel printing packaging method and system based on 3D printing

A 3D printing and multi-tasking technology, applied in the field of 3D printing, can solve problems such as lack of 3D printing services, achieve the effect of improving the molding process time, improving utilization rate, and reducing the average time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

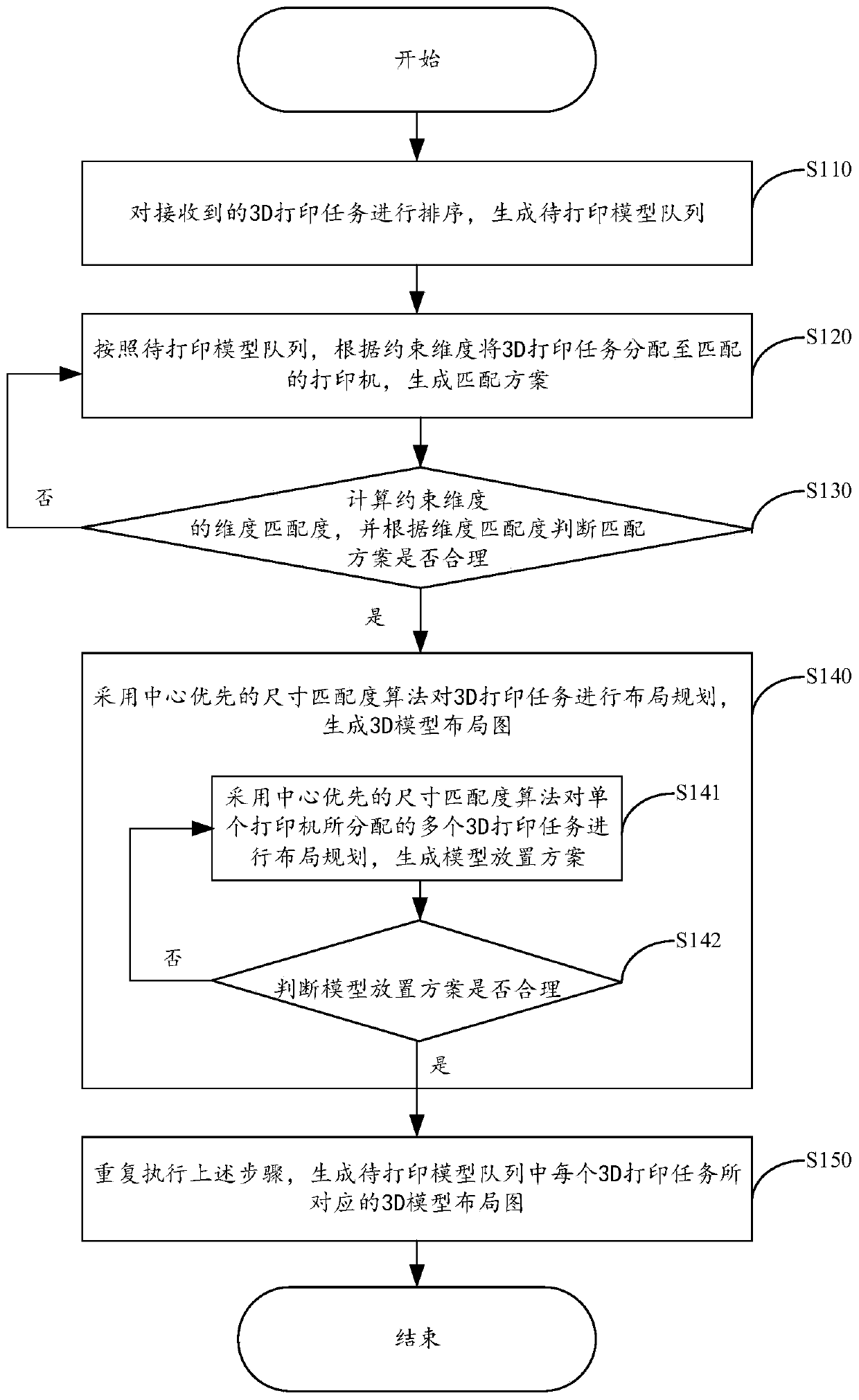

[0060] figure 1 It is a flow chart of the 3D printing multi-task parallel printing and packaging method provided by Embodiment 1 of the present invention.

[0061] like figure 1 As shown, the embodiment of the present invention provides a 3D printing multi-task parallel printing and packaging method, which may include the following steps:

[0062] Sorting step S110: sort the received 3D printing tasks, and generate a queue of models to be printed.

[0063] Specifically, the received 3D printing tasks are stored in reverse order by using a stack method to generate a queue of models to be printed. Receiving 3D printing tasks on a 3D printing platform in a distributed environment is a process of dynamic update. The 3D printing tasks are stored in the form of a stack, which is conducive to the dynamic update of newly added tasks to be printed in the whole process. In order to ensure the real-time update of tasks Effective sorting, the 3D printing tasks are sorted in reverse ord...

Embodiment 2

[0113] Figure 4 It is a schematic diagram of a 3D printing multi-task parallel printing packaging system provided by Embodiment 2 of the present invention.

[0114] The embodiment of the present invention also provides a 3D printing-based multi-task parallel printing and packaging system, which is used to realize the 3D printing-based multi-task parallel printing and packaging method provided in the above embodiment, refer to Figure 4 , the 3D printing-based multi-task parallel printing packaging system includes the following units:

[0115] Sorting unit 100: sort the received 3D printing tasks, and generate a queue of models to be printed;

[0116] Matching unit 200: according to the model queue to be printed, distribute the 3D printing task to the matching printer according to the constraint dimension, and generate a matching scheme;

[0117] Judging unit 300: calculating the dimension matching degree of the constraint dimension, and judging whether the matching scheme i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com