Back structure of thermo-photovoltaic cell

A technology of thermal photovoltaic cells and back, applied in photovoltaic power generation, circuits, electrical components, etc., to achieve the effect of facilitating collection and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further explained below in conjunction with the drawings.

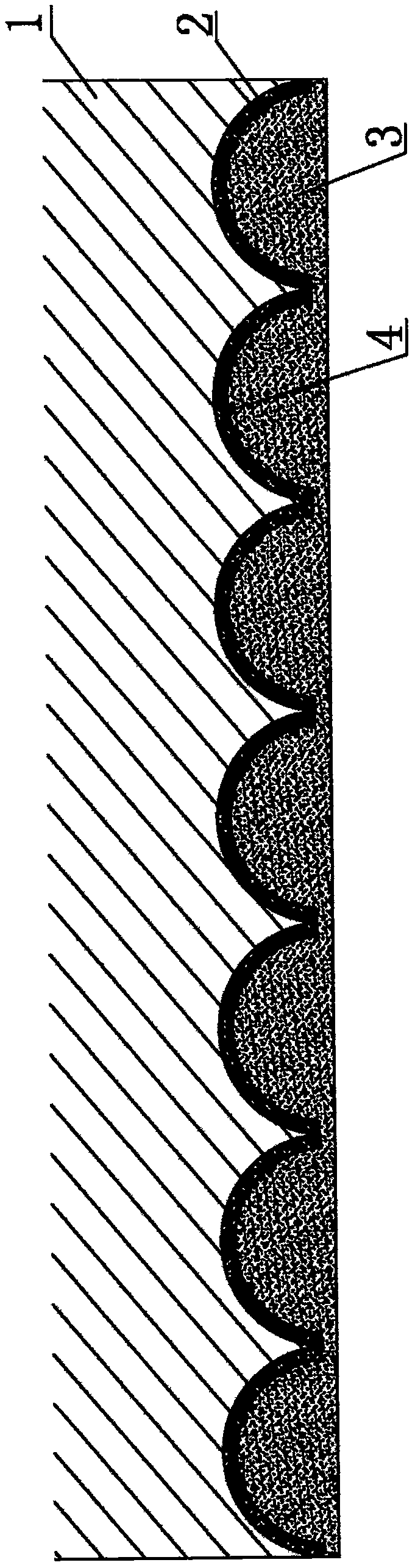

[0009] Such as figure 1 As shown, the present invention is a back structure of a thermal photovoltaic cell, including a cadmium telluride layer 1, which is characterized in that a groove 4 is formed on the back of the cadmium telluride layer 1, and 5 to 5 are provided in the groove 4. The silicon dioxide film layer 2 of 10 nanometers has an aluminum layer 3 printed on the surface of the silicon dioxide film layer 2.

[0010] The present invention is obtained through the following steps:

[0011] (1) Use an infrared laser to make a groove 4 on the back of the cadmium telluride layer 1, with a hole diameter of 800-1500 nanometers and a hole depth of 400-750 nanometers;

[0012] (2) Use a certain concentration of hydrofluoric acid to clean the surface of the groove 4;

[0013] (3) Perform thermal oxidation treatment on the surface of the groove 4 to form a 5-10 nanometer silicon dioxide film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com