Ultralow-temperature lithium-ion battery and preparation method thereof

A lithium-ion battery, ultra-low temperature technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of non-normal use, decreased discharge capacity, decreased discharge rate performance, etc., to compensate for the decrease in conductivity and improve the isotropy , The effect of good material capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

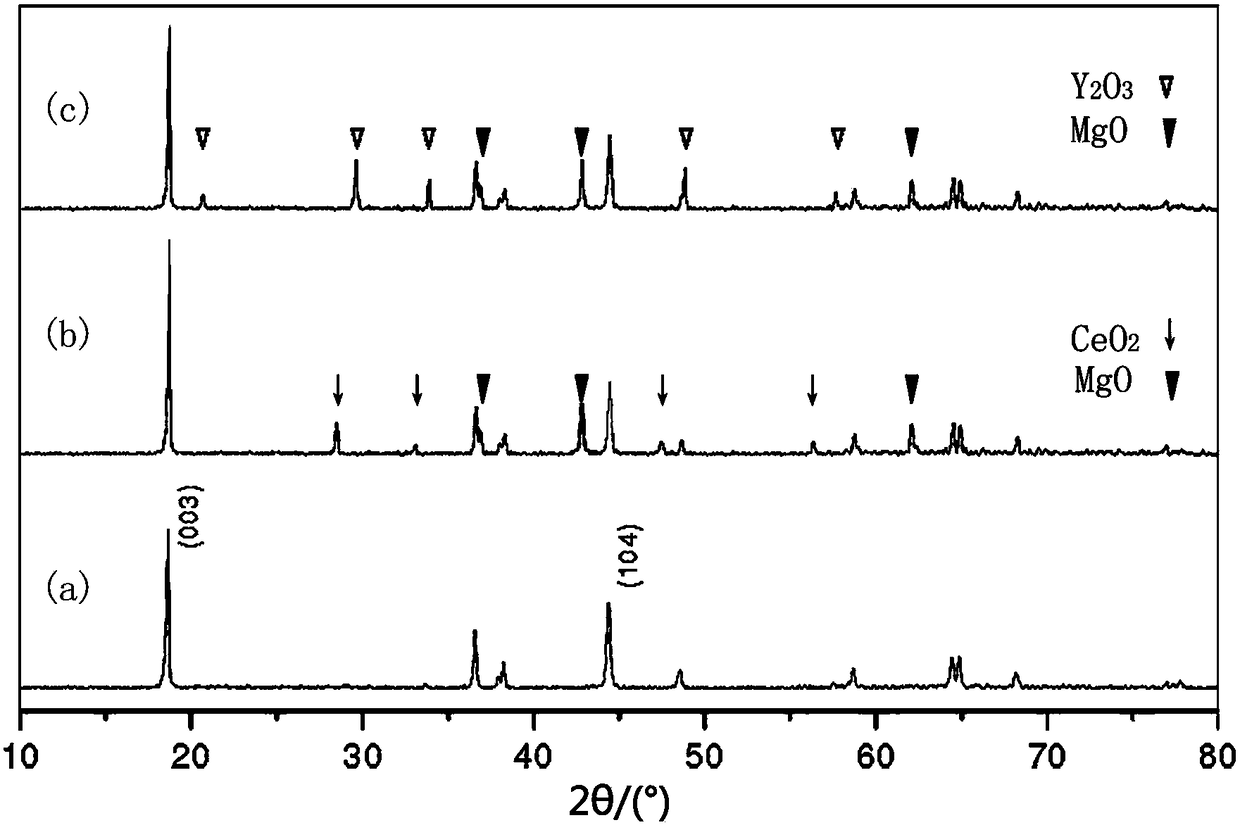

[0029] A method for preparing a positive electrode active material. First, uniformly mix rare earth metal oxides and alkaline earth metal oxides at a mass ratio of 1:1, and then add 0.05-5 parts of mixed powder to 100 parts of LiCoO 2 Among them, sinter after mixing evenly to form LiCoMO compound, which can be obtained after jet milling and classification, where M represents a mixture of rare earth elements and alkaline earth metals.

[0030] Further, the sintering conditions are sintering at a temperature of 850°C-950°C for 10h-15h in an inert gas atmosphere; the rare earth elements include one of Sc, Y, La, Ce, Nd, Gd and Sm, so The alkaline earth metals include Mg.

[0031] A positive electrode active material, the positive electrode active material is prepared by the above preparation method, and the particle size D50 of the positive electrode active material is 4 μm-7 μm.

[0032] A method for preparing an ultra-low temperature lithium-ion battery, first preparing positi...

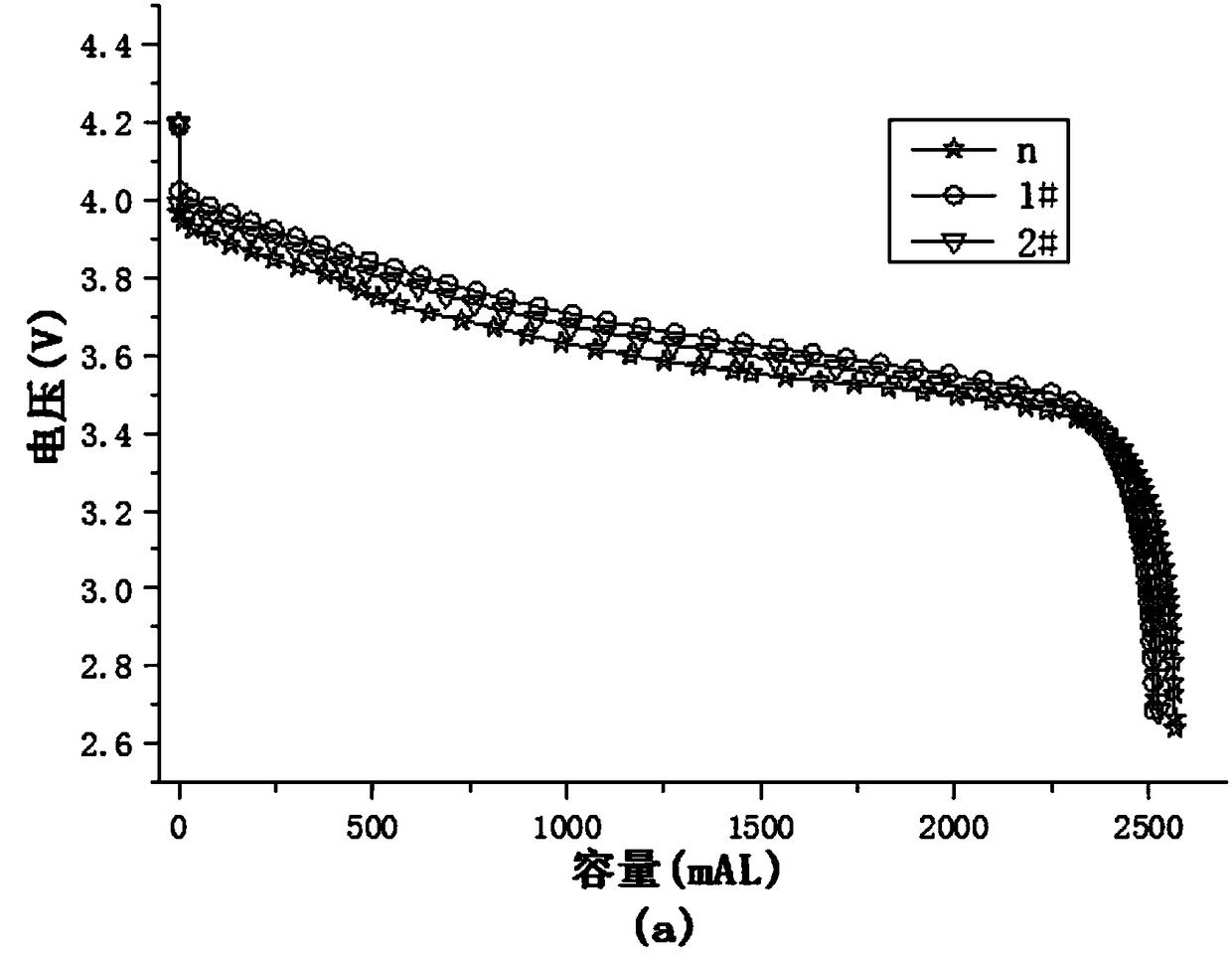

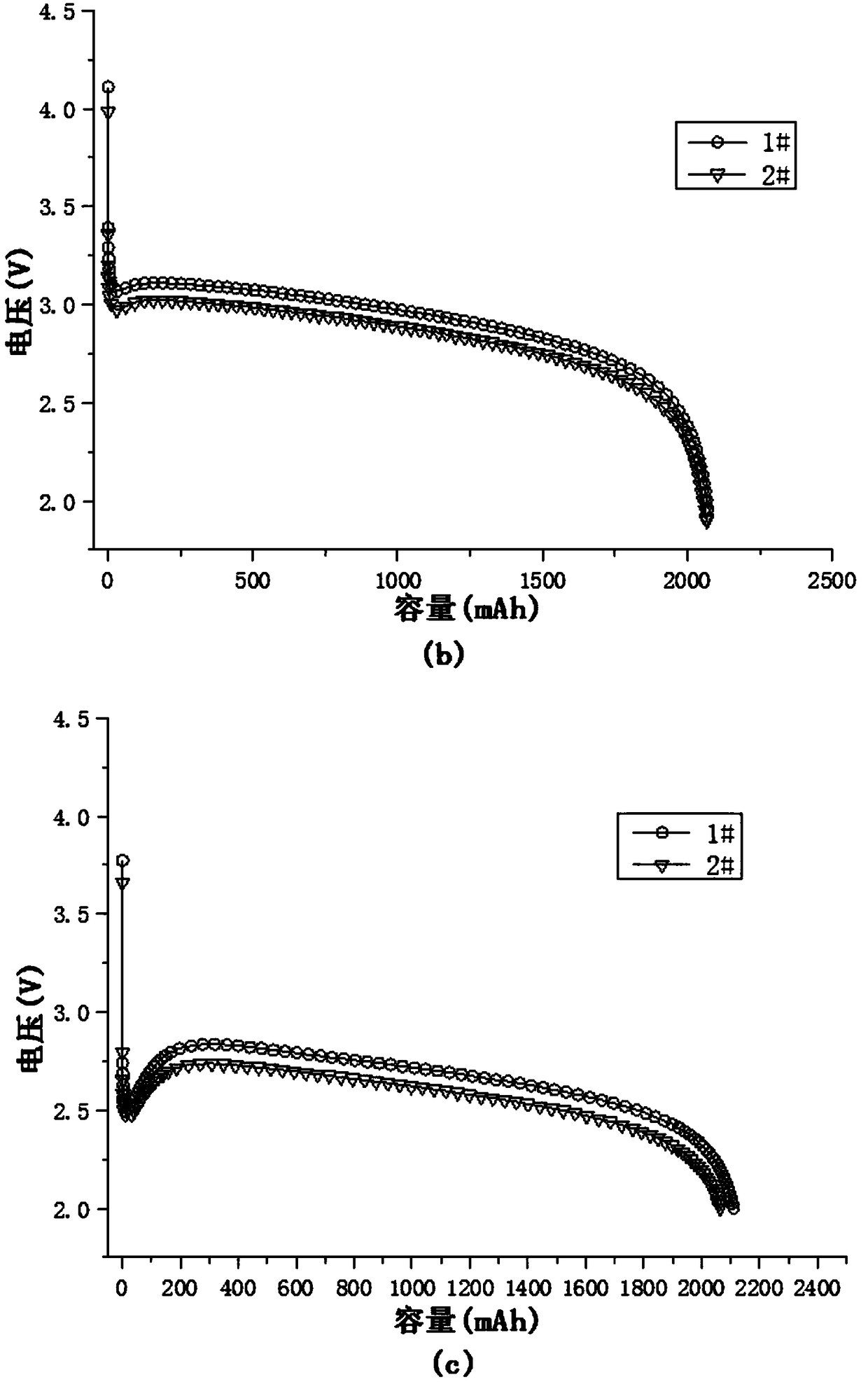

Embodiment 1

[0047] A method for preparing positive electrode active materials, firstly, CeO with a particle size of 10 μm-30 μm 2 Mix evenly with MgO at a mass ratio of 1:1, and then add 4 parts of the mixed powder to 100 parts of LiCoO 2 In, and mixed uniformly; then sintered to form a LiCoMO compound, which is obtained after jet milling and classification, where M represents a mixture of Ce and Mg.

[0048] Further, the sintering condition is sintering at a temperature of 950° C. for 10 h in an inert gas atmosphere; in this embodiment, the rare earth element is Ce, and the alkaline earth metal is Mg.

[0049] A positive electrode active material, the positive electrode active material is prepared by the above preparation method, and the particle size D50 of the positive electrode active material is 4 μm-7 μm.

Embodiment 2

[0051] A method for preparing positive electrode active materials, firstly, CeO with a particle size of 10 μm-30 μm 2 and MgO in a mass ratio of 1:1, and then in parts by mass, take 2 parts of the mixed powder and add it to 100 parts of LiCoO 2 In, and mixed uniformly; then sintered to form a LiCoMO compound, which is obtained after jet milling and classification, where M represents a mixture of Ce and Mg.

[0052] Further, the sintering condition is sintering at a temperature of 900° C. for 13 hours in an inert gas atmosphere; in this embodiment, the rare earth element is Ce, and the alkaline earth metal is Mg.

[0053] A positive electrode active material, the positive electrode active material is prepared by the above preparation method, and the particle size D50 of the positive electrode active material is 4 μm-7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com