Flexible grinding type automatic compensating system

An automatic compensation and flexible technology, applied in the direction of grinding automatic control devices, grinding machines, grinding machine parts, etc., can solve the problems of low product precision, uneven surface quality of workpieces, poor consistency of workpieces, etc., to ensure consistency and Quality, reasonable design, the effect of improving grinding efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

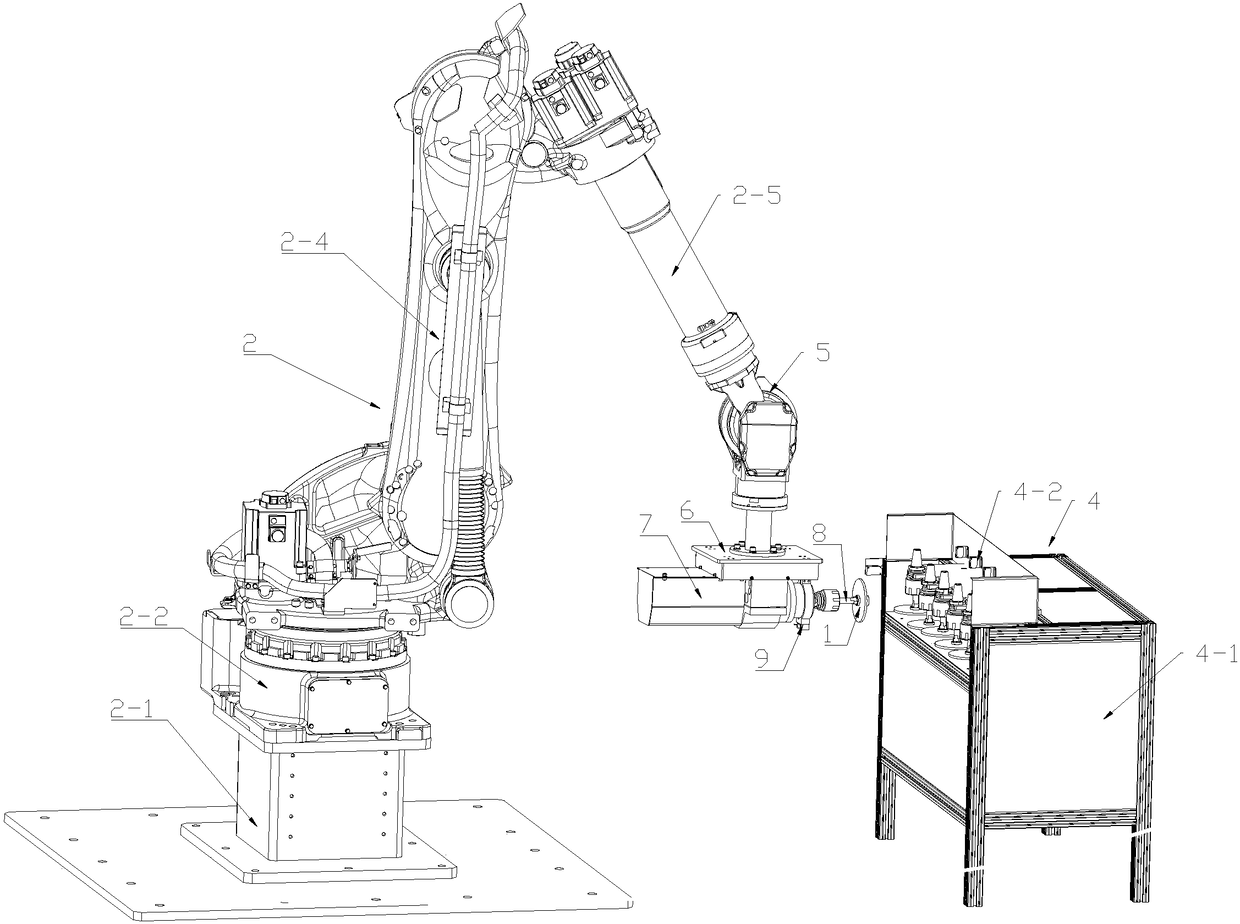

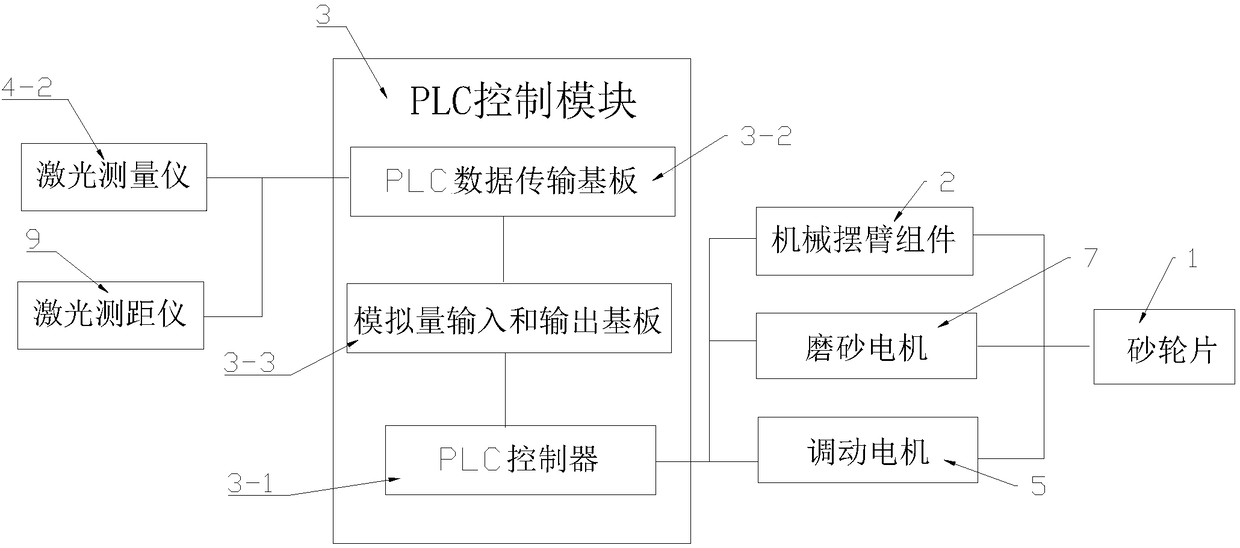

[0012] Such as Figure 1-2 As shown, a flexible grinding automatic compensation system includes a grinding wheel 1 for grinding, a mechanical swing arm device 2 for controlling and adjusting the grinding angle and grinding depth of the grinding wheel 1, a PLC control module 3, monitoring the grinding condition of the grinding wheel 1 and Replace the monitoring device 4 of the grinding wheel sheet 1 in time, wherein the output end of the mechanical swing arm device 2 is hinged with a motor seat 6 by mobilizing the motor 5, and the motor seat 6 is fixed with a grinding motor 7, and the output end of the grinding motor 7 The center of the grinding wheel piece 1 is fixedly connected through the output shaft 8, the output shaft 8 is locked and connected with the grinding wheel piece 1 through a strong handle, so as to achieve a stable connection effect of the grinding wheel piece 1, and the grinding motor 7 is also fixed with a scannable A laser rangefinder 9 for the workpiece need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com