Quantum-dot dispersed resin forming body, preparation method thereof and quantum-dot dispersed body

A technology for dispersing resins and quantum dots, applied in the field of optics, can solve the problem of single dispersion medium of quantum dots, and achieve the effects of improving comprehensive performance, stability, and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

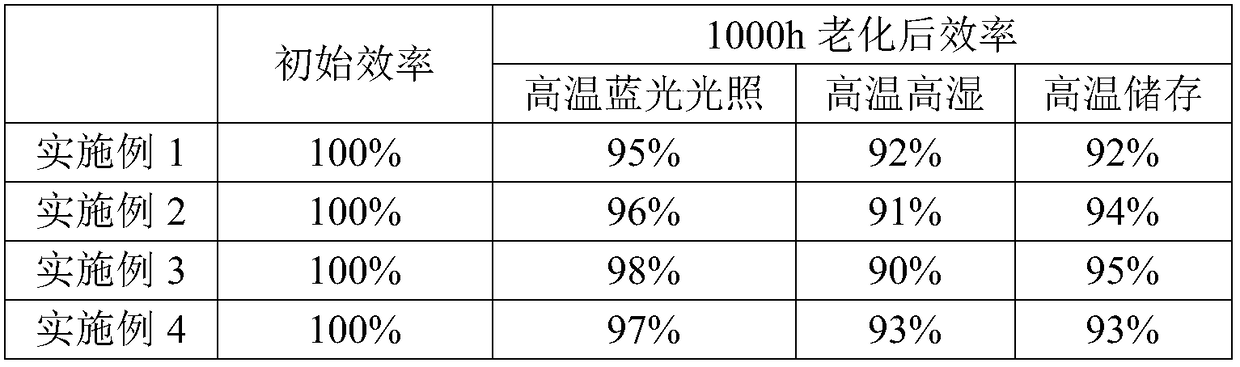

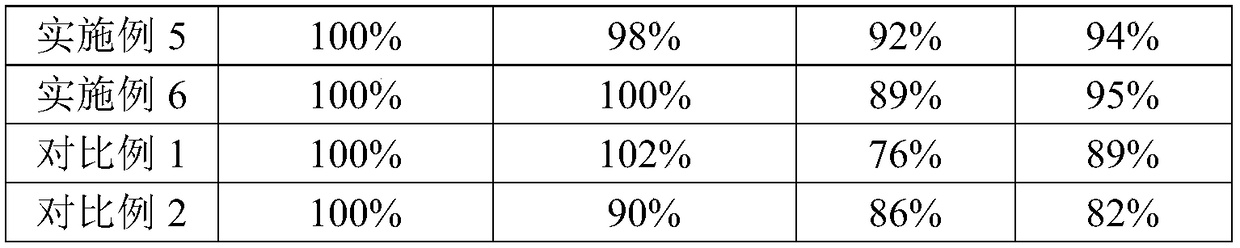

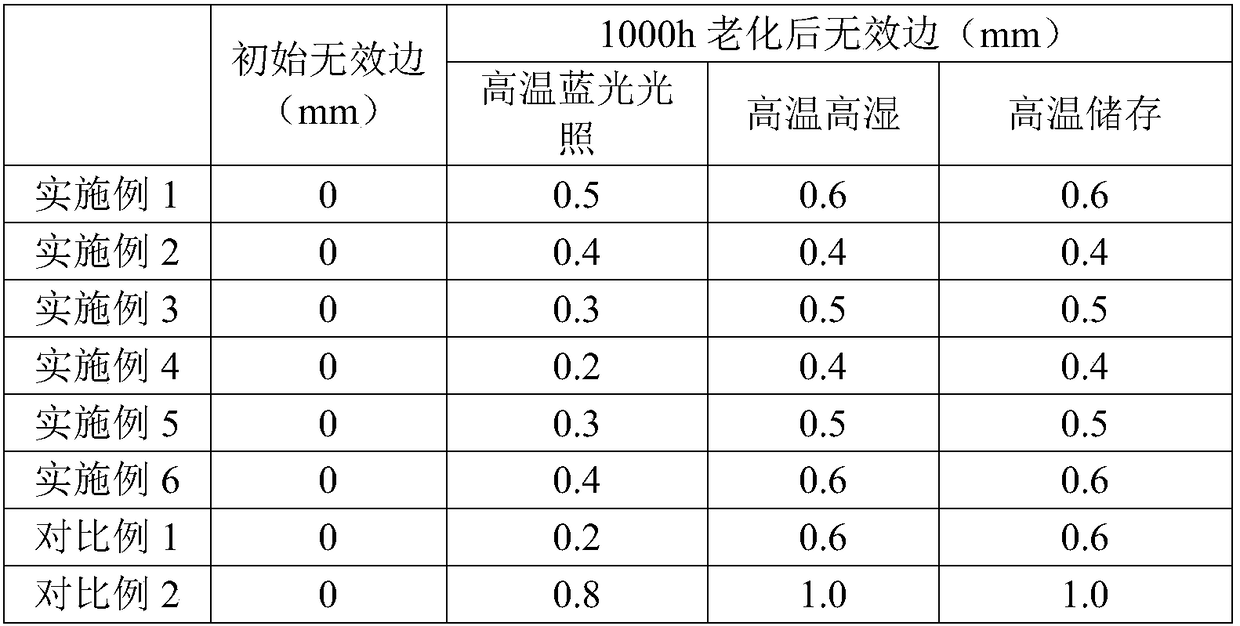

Examples

preparation example Construction

[0041] The preparation of quantum dot dispersion colloid comprises the following steps:

[0042] S1. Dissolve the water-soluble quantum dots in the hydrophilic resin and mix evenly. The hydrophilic resin should be selected from one or more of the following: (meth)acrylic acid, N-methylol acrylamide, hydroxyethyl acrylamide, poly Ethylene glycol diacrylate, 2-hydroxyethyl (meth)acrylate, 2-hydroxypropyl (meth)acrylate;

[0043] S2. Add an amphiphilic resin to the mixture obtained in step S1 and mix evenly. The amphiphilic resin is selected from one or more of the following: dimethylacrylamide, acryloylmorpholine, dimethylaminopropylacrylamide, Diethylacrylamide, N-vinylpyrrolidone;

[0044] S3. Add hydrophobic resin to the mixture obtained in step S2, and mix evenly. The hydrophobic resin is selected from one or more of the following: methyl (meth)acrylate, ethyl (meth)acrylate, (meth)acrylic acid n-butyl ester, lauryl (meth)acrylate, 2-ethylhexyl (meth)acrylate, cyclohexyl (...

Embodiment 1

[0064] A method for preparing a quantum dot dispersed resin molding, wherein the quantum dot is a water-soluble quantum dot, comprising the following steps:

[0065] S1. Dissolve 0.1 parts by mass of water-soluble quantum dots in 5 parts by mass of 2-hydroxyethyl methacrylate, and mix uniformly;

[0066] S2. Add 5 parts by mass of acryloylmorpholine to the mixture obtained in step S1, and mix well;

[0067] S3. Add 90 parts by mass of isodecyl methacrylate to the mixture obtained in step S2, and mix uniformly;

[0068] S4, adding a curing agent in step S1 or S2 or S3, placing the mixture obtained in step S3 on the substrate, cross-linking and curing the resins in the mixture, and obtaining the quantum dot dispersed resin molded body of Example 1.

Embodiment 2

[0070] A method for preparing a quantum dot dispersed resin molding, wherein the quantum dot is a water-soluble quantum dot, comprising the following steps:

[0071] S1. Dissolve 1 mass part of water-soluble quantum dots in 40 mass parts of 2-hydroxyethyl methacrylate, and mix uniformly;

[0072] S2. Add 30 parts by mass of acryloylmorpholine to the mixture obtained in step S1, and mix well;

[0073] S3. Add 30 parts by mass of 2-ethylhexyl methacrylate to the mixture obtained in step S2, and mix well;

[0074] S4, adding a curing agent in step S1 or S2 or S3, placing the mixture obtained in step S3 on the substrate, cross-linking and curing the resins in the mixture, and obtaining the quantum dot dispersed resin molded body of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com