Multistage series-parallel connected type oil-water separating equipment adopting crude oil emulsion breaking

A crude oil demulsification oil and oil-water separation technology, which is applied in the field of multi-stage series-parallel crude oil demulsification oil-water separation device, can solve the problems of complex equipment, poor stability of crude oil demulsification and dehydration effect, and high cost, and achieve uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

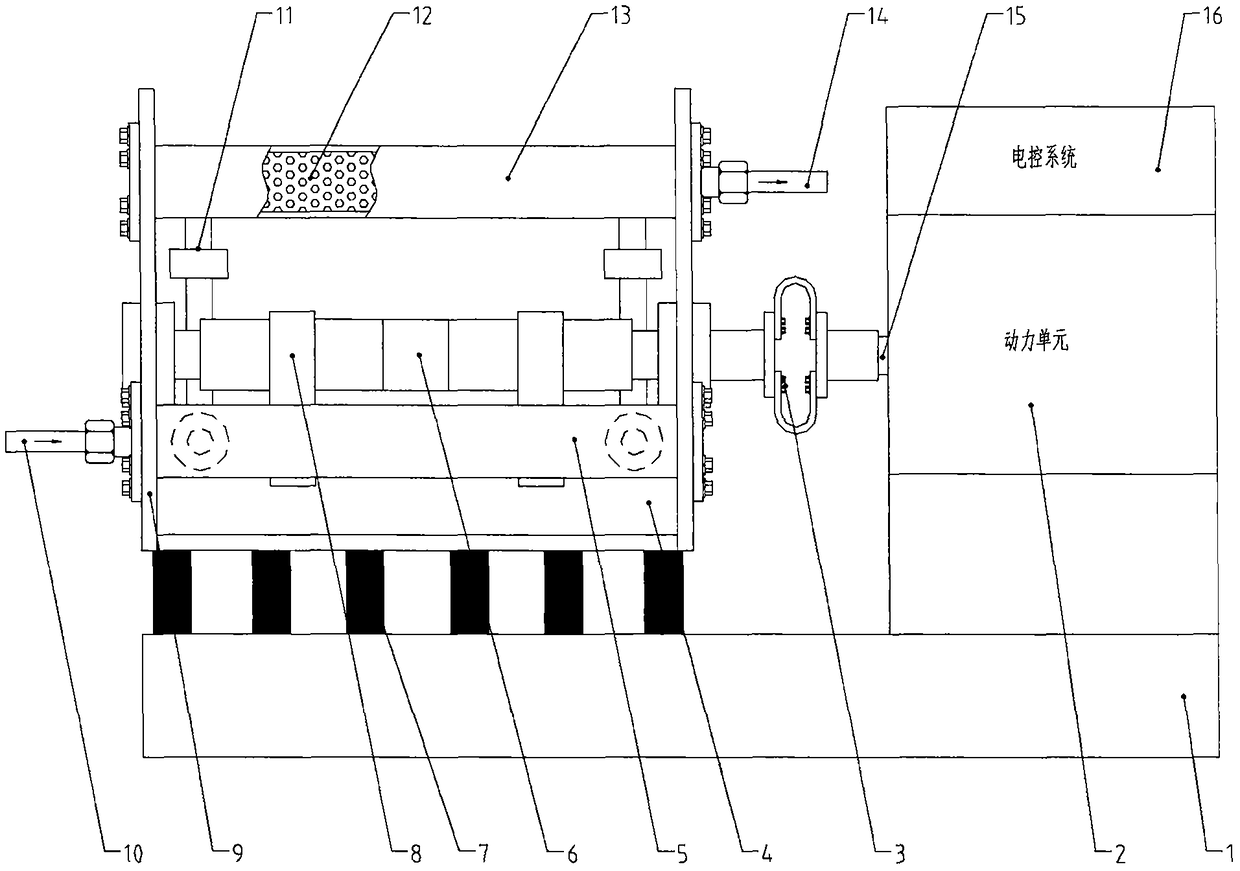

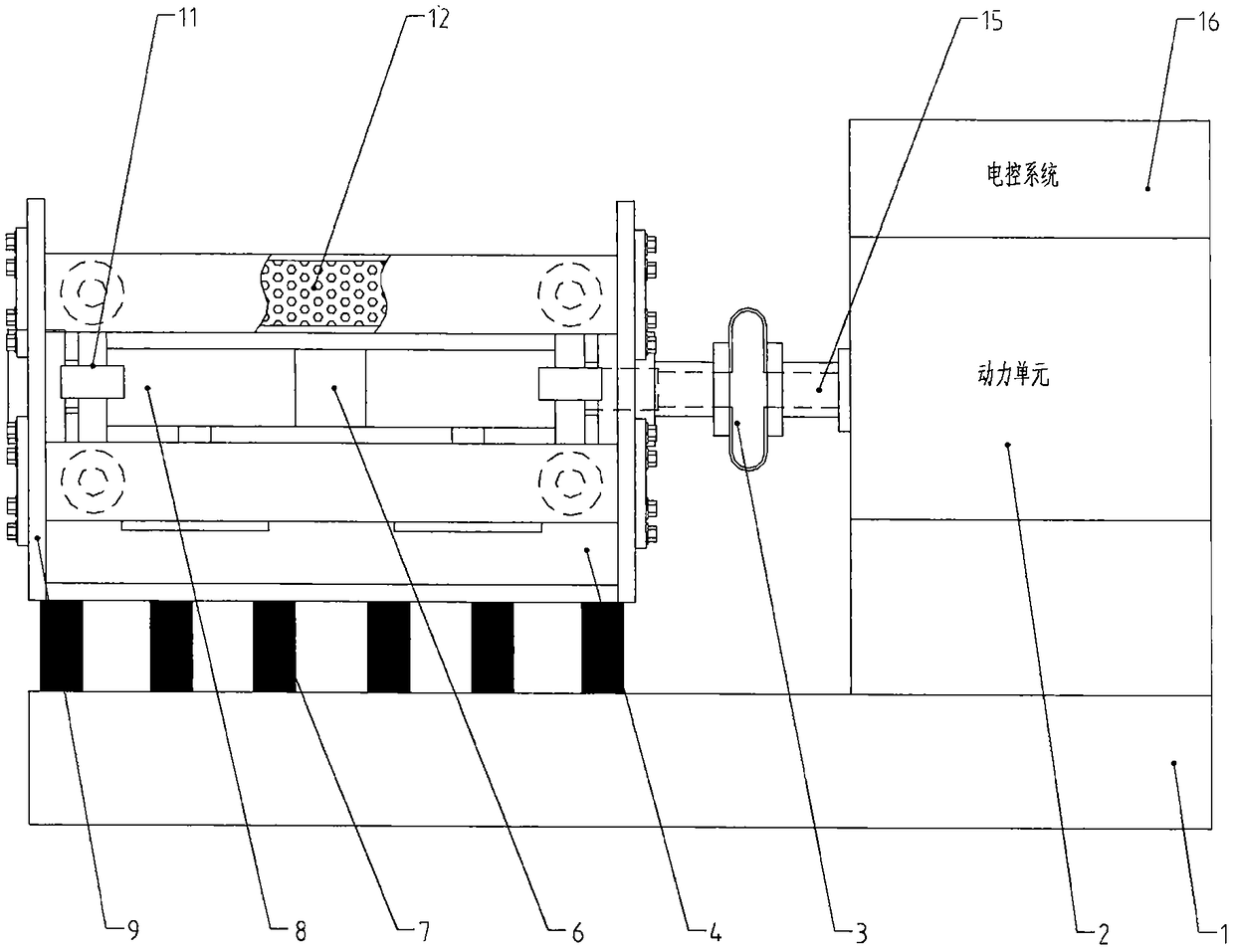

[0041] This embodiment adopts as Figure 4 The demulsification device shown is a feed oil-water separation pipe, a discharge oil-water separation pipe, and two intermediate oil-water separation pipes.

[0042] The physical properties of the emulsified crude oil sample are as follows:

[0043] Table 1 Analysis results of physical properties of oil samples

[0044]

[0045] It can be seen from Table 1 that the station oil samples belong to light, low-viscosity, medium-condensing crude oil. The experimental temperature is 40°C, and the water content in crude oil is 6.6% by volume.

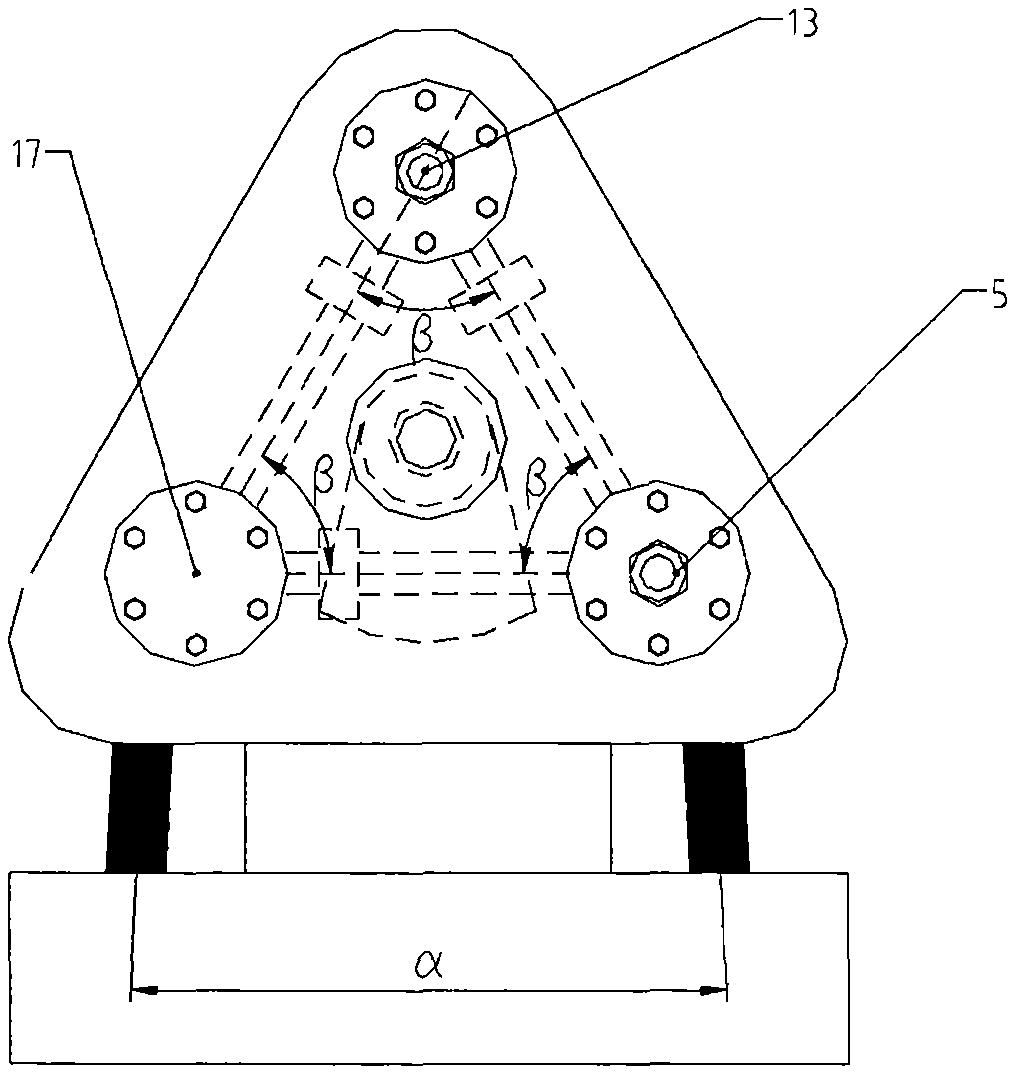

[0046] Turn on the power unit 2, drive the vibration shaft 6 through the output shaft 15 to drive the vibration exciter 8 to generate vibration, and finally make the vibration bracket 9, the feed oil-water separation pipe 5, the middle oil-water separation pipe 17, and the discharge oil-water separation pipe 13 , shunt 11, and the integrated structural vibration device 4 of the excitation shaft ...

Embodiment 2

[0051] This embodiment adopts as Figure 4 The demulsification device shown is a feed oil-water separation pipe, a discharge oil-water separation pipe, and two intermediate oil-water separation pipes. Oil sample condition is identical with embodiment 1.

[0052] Turn on the power unit 2, drive the vibration shaft 6 through the output shaft 15 to drive the vibration exciter 8 to generate vibration, and finally make the vibration bracket 9, the feed oil-water separation pipe 5, the middle oil-water separation pipe 17, and the discharge oil-water separation pipe 13 , shunt 11, and the integrated structural vibration device 4 of the excitation shaft 6 perform overall high-frequency vibration relative to the equipment base 1 . Among them, the oil-water separation pipe has a length of 0.5m and a diameter of 8cm. The vibration medium in the oil-water separation pipe is a steel rod with a length of 0.4m and a vibration frequency of 20Hz.

[0053] The oil sample in Example 1 is conti...

Embodiment 3

[0058] This embodiment adopts as Figure 4 The demulsification device shown is a feed oil-water separation pipe, a discharge oil-water separation pipe, and two intermediate oil-water separation pipes. Oil sample condition is identical with embodiment 1.

[0059] Turn on the power unit 2, drive the vibration shaft 6 through the output shaft 15 to drive the vibration exciter 8 to generate vibration, and finally make the vibration bracket 9, the feed oil-water separation pipe 5, the middle oil-water separation pipe 17, and the discharge oil-water separation pipe 13 , shunt 11, and the integrated structural vibration device 4 of the excitation shaft 6 perform overall high-frequency vibration relative to the equipment base 1 . Among them, the oil-water separation pipe has a length of 0.5m and a diameter of 8cm. The vibration medium in the oil-water separation pipe is a steel rod with a length of 0.4m and a vibration frequency of 30Hz.

[0060] The oil sample of Example 1 is conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com