Cathode vacuum arc plasma magnetic filter device and application thereof

A cathode vacuum arc and plasma technology, which is applied in the directions of filtration and separation, ion implantation plating, vacuum evaporation plating, etc., to achieve the effect of improving uniformity and high movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

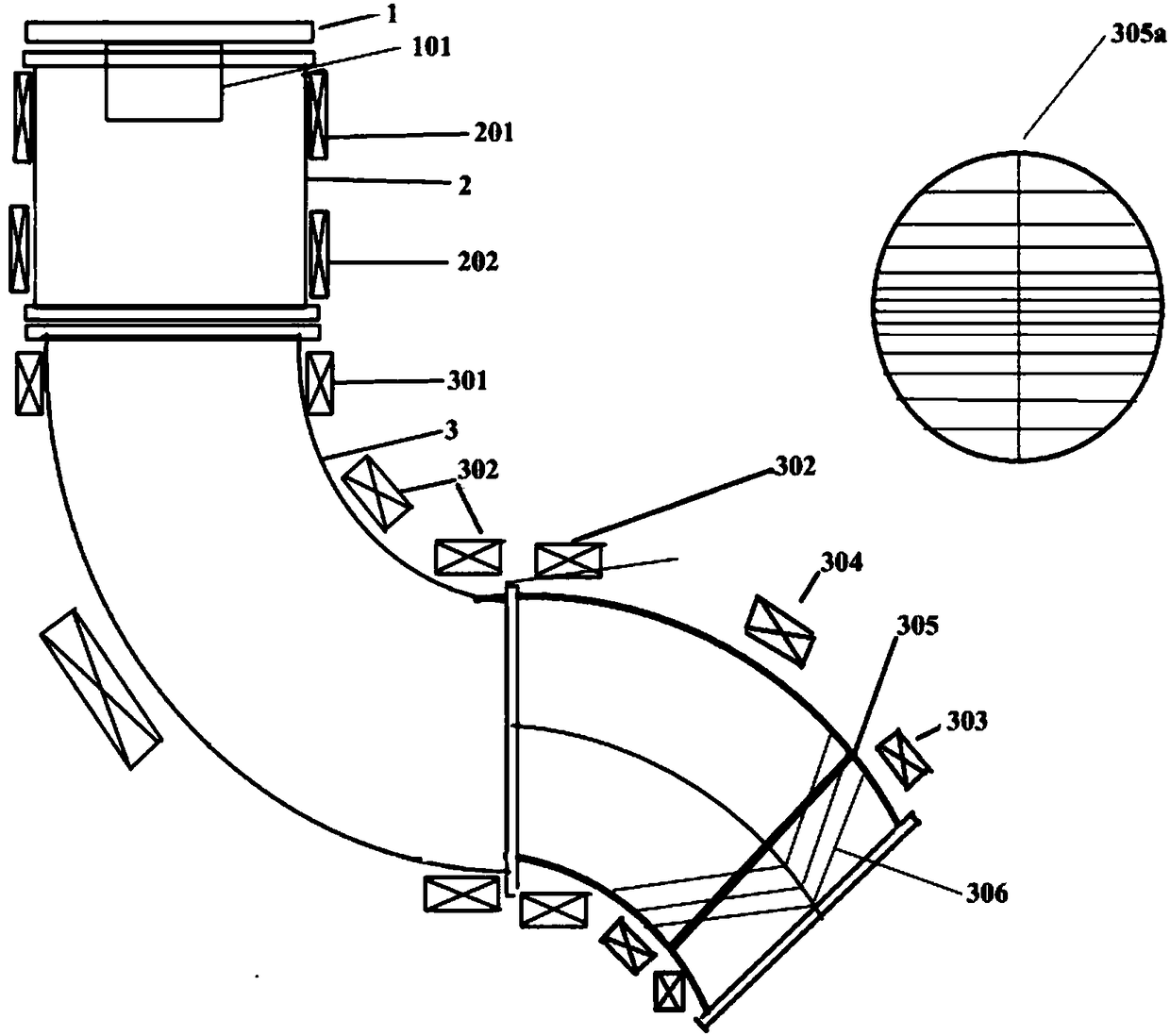

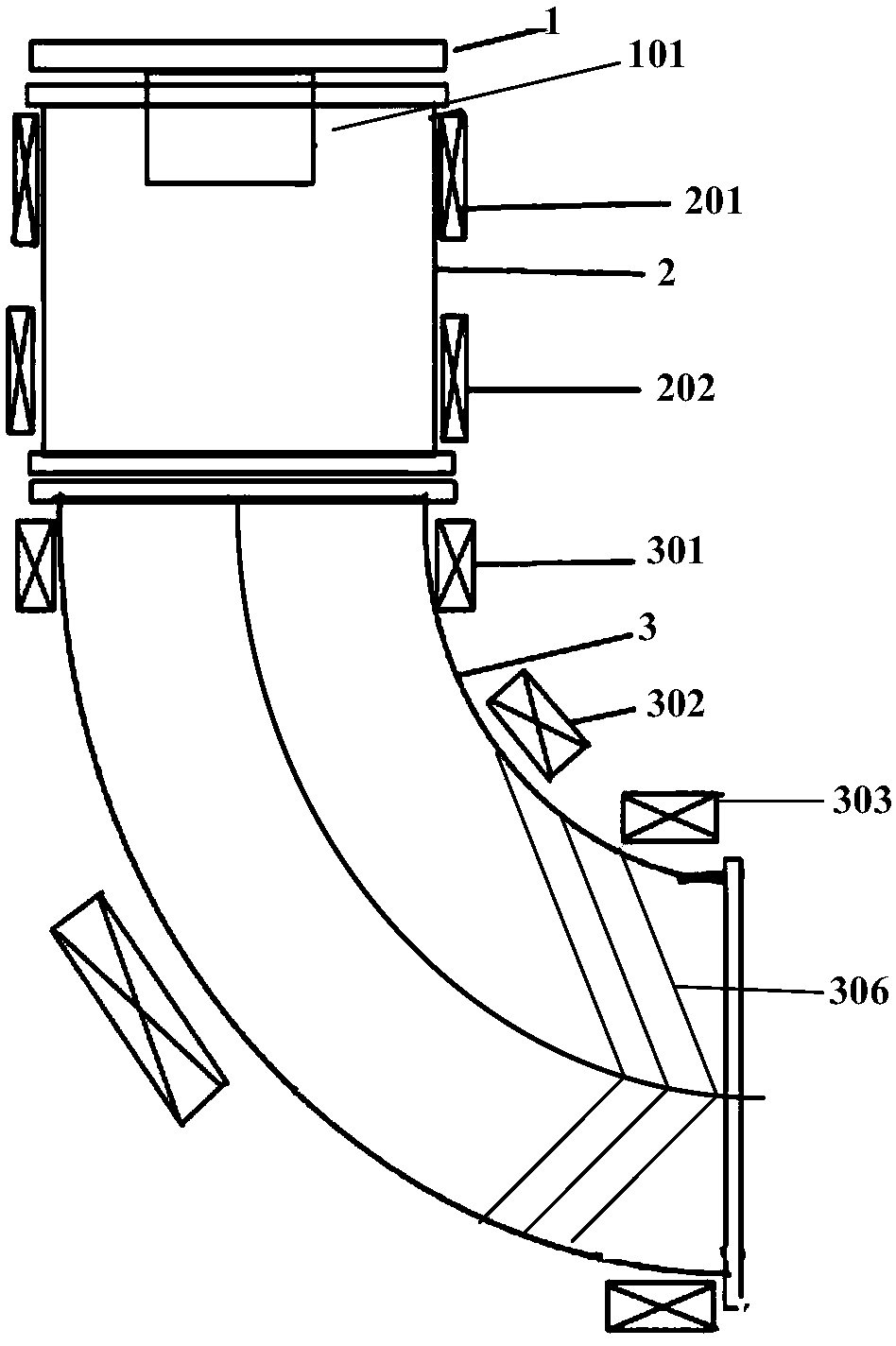

[0055] The structure of the cathode vacuum arc plasma magnetic filter device according to one embodiment of the present invention is listed below.

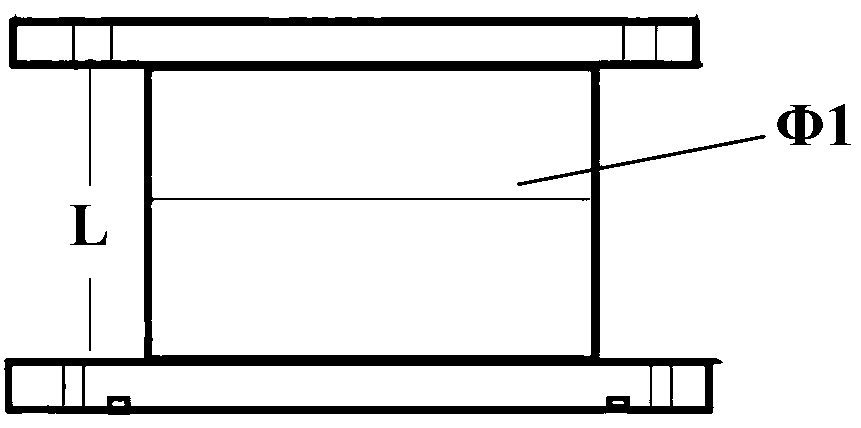

[0056] The cathode vacuum arc plasma magnetic filter device includes an arc head 1, an anode cylinder 2 and a magnetic filter elbow 3; the arc head 1 is connected to the first end of the anode cylinder 2, and the second end of the anode cylinder 2 is connected to the magnetic filter elbow 3 connect. The connection method is flange connection.

[0057] The anode cylinder 2 is sequentially provided with a first strong pulse line package 201 and a suppression line package 202; the magnetic filter elbow 3 is a combination of a 90° elbow and a 45° elbow, and the magnetic filter elbow 3 is sequentially provided with a second strong pulse The pulse line package 301 , the middle line package 302 and the high pulse defocus line package 303 ; wherein, the number of the middle line package 302 is three groups. The winding direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com