Oblique flow fan having anti-corrosion function

A diagonal flow fan, functional technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of no anti-corrosion, short motor service life, etc., to achieve high cost, increase air pressure and air volume, ensure The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

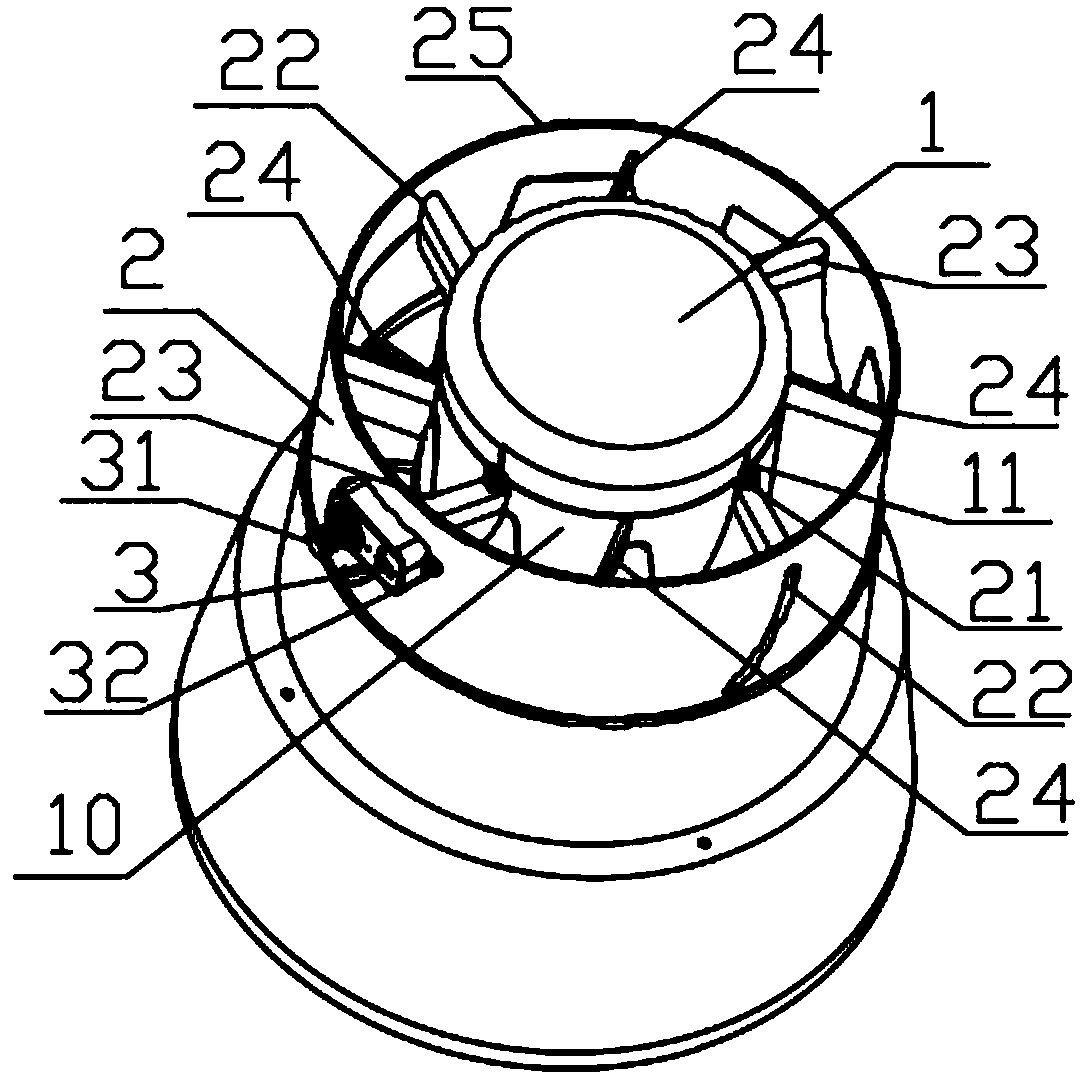

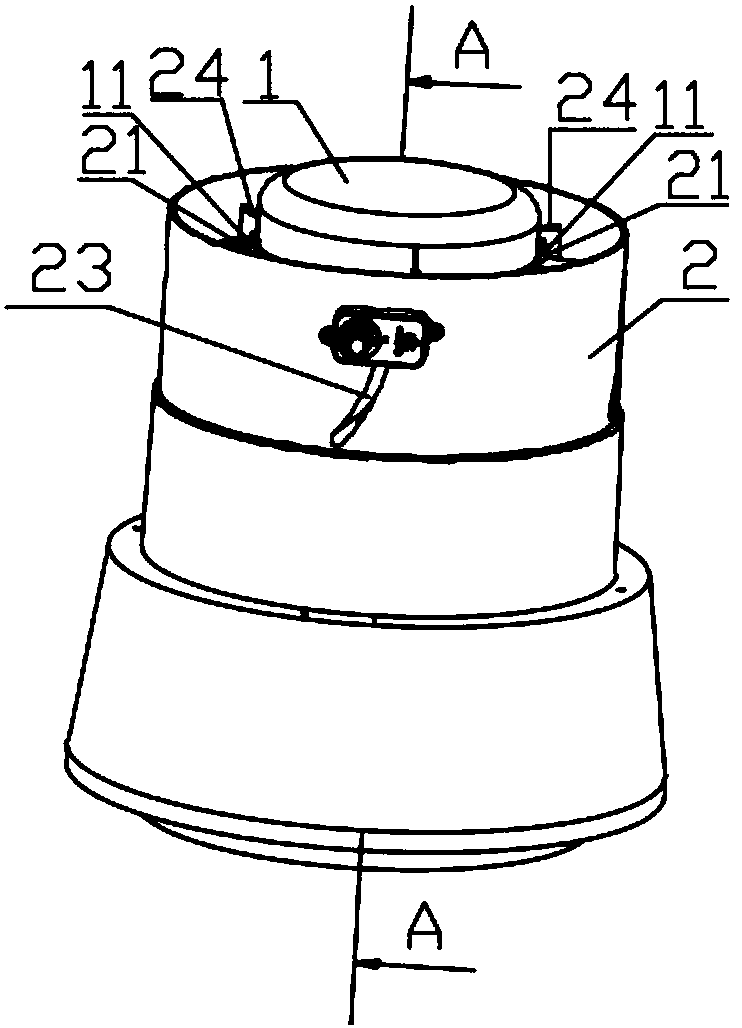

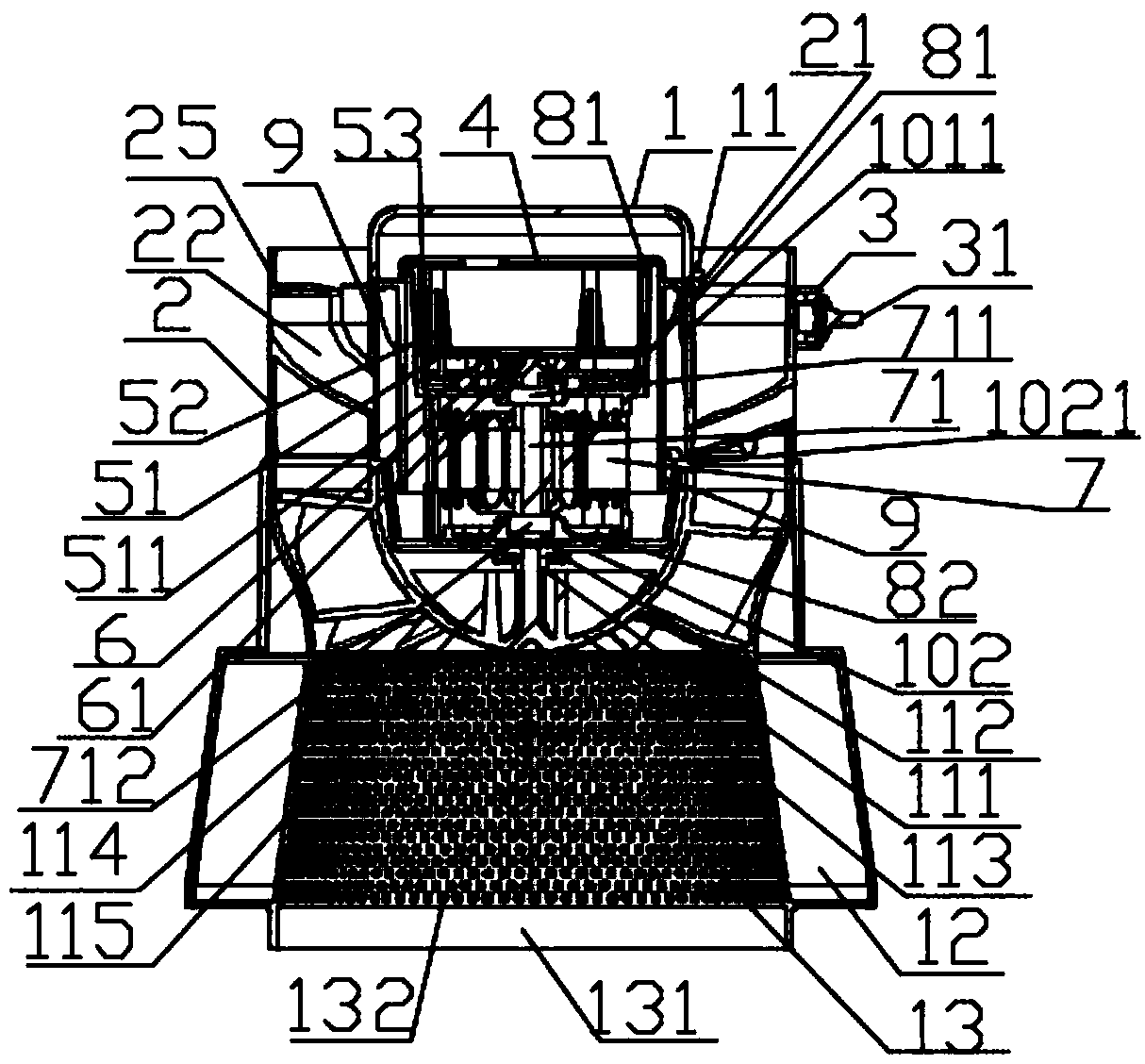

[0042] Such as figure 1 Shown is the perspective view of the first angle of view of the oblique flow fan of the present invention, as figure 2 Shown is the perspective view of the second angle of view of the oblique flow fan of the present invention, as image 3 Shown is the A-A plane sectional view of the second viewing angle of the oblique flow fan of the present invention, as Figure 4 Shown is the structural representation that the oblique flow fan of the present invention removes outer cover 2, as Figure 5 Shown is the perspective view of the third viewing angle of the inclined flow fan of the present invention.

[0043] A diagonal flow fan with anti-corrosion function, which includes: a bottom cover 1, an outer cover 2, a circuit board 4, a first diversion chamber 5, a small impeller 6, a brushless motor 7, a motor shaft fixing bracket 8, and a motor protection cover 9 1. The inner cover 10 and the moving impeller 11 are characterized in that: the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com