Magnetoelectric coupling composite material with adjustable resonance mode and preparation method thereof

A technology of magnetoelectric coupling and composite materials, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, magnetostrictive devices, etc., can solve the problem of single resonance mode, and achieve the effect of low price and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

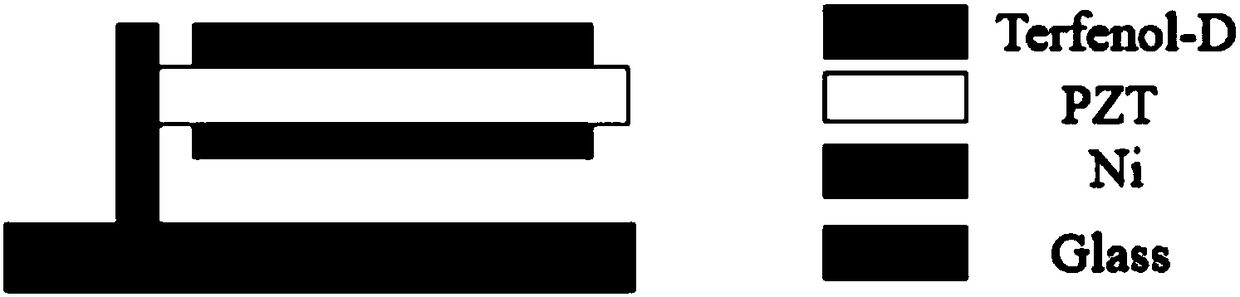

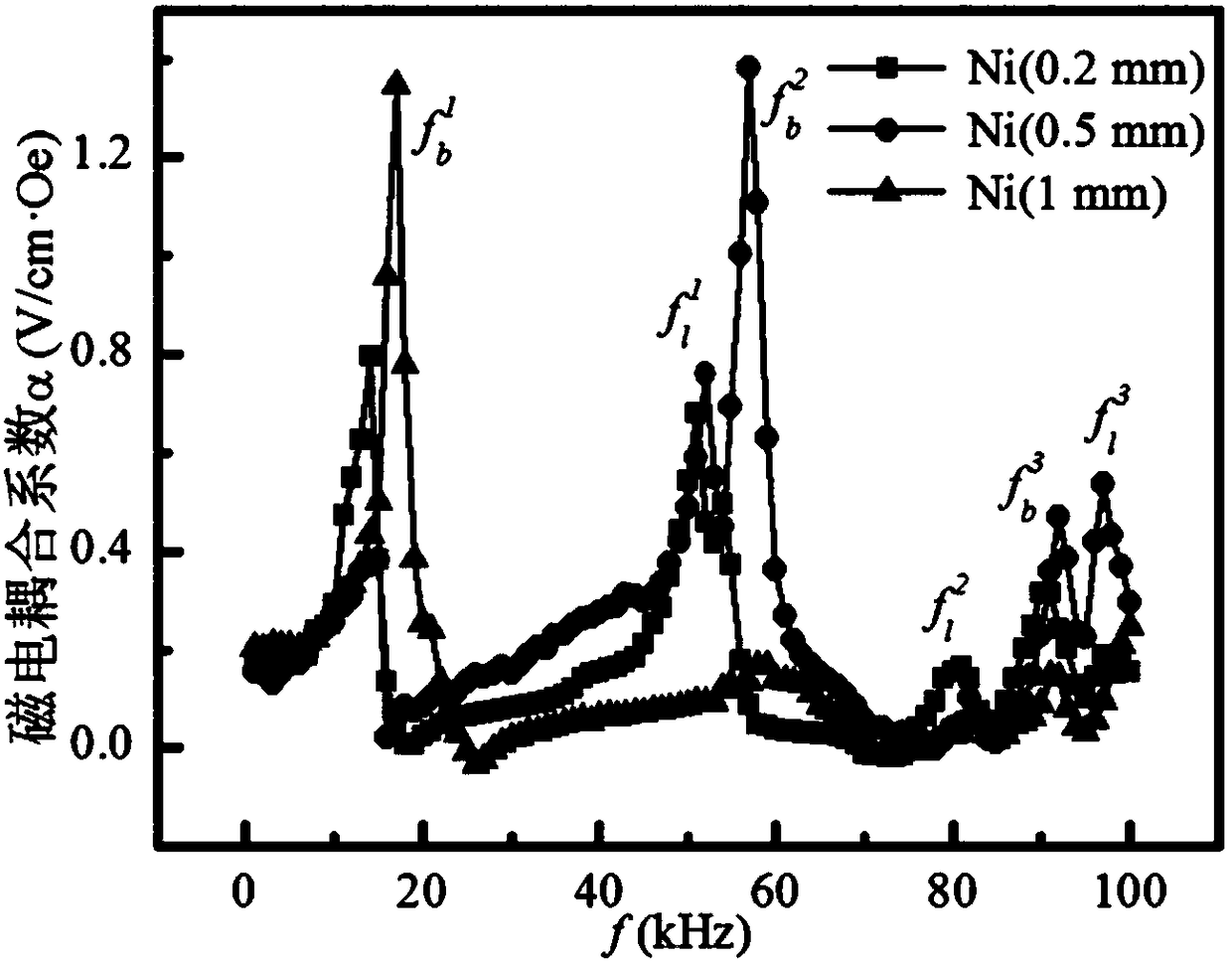

[0023] The magnetoelectric coupling composite material maintains the thickness of Terfenol-D as 0.5mm, and the thickness of Ni is 0.2mm, 0.5mm, 1mm respectively, and the thickness ratio of the positive and negative magnetostrictive layers (Terfenol-D and Ni) is kept as Three samples of 1:0.4, 1:1, 1:2.

[0024] Step 1: Take two glass slides, one of which is cut with a glass knife into a strip with a length of 15mm, a width of 5mm, and a thickness of 1mm, that is, a strip with a size of 15mm×5mm×1mm, and then cut the slides with epoxy resin. The long glass slides are vertically glued to another glass slide to form a T-shaped structure, and left to dry for 48 hours, making 3 pieces in total.

[0025] Step 2: Bond the PZT with the size of 20mm×5mm×1mm and the Terfenol-D with the size of 15mm×5mm×0.5mm on the front of the PZT with epoxy resin adhesive, where the two ends of the PZT are respectively left 2.5mm vacant part, and then stick the nickel sheet with the size of 15mm×5mm×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com