Isostatic pressing forming mold of rotating target

A technology of isostatic pressing and rotating target, which is applied in the direction of moulds, ceramic molding machines, ceramic molding cores, etc., can solve problems such as the trumpet-shaped deformation of the green blank, so as to prolong the service life, improve the sharp deformation, and avoid being torn. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

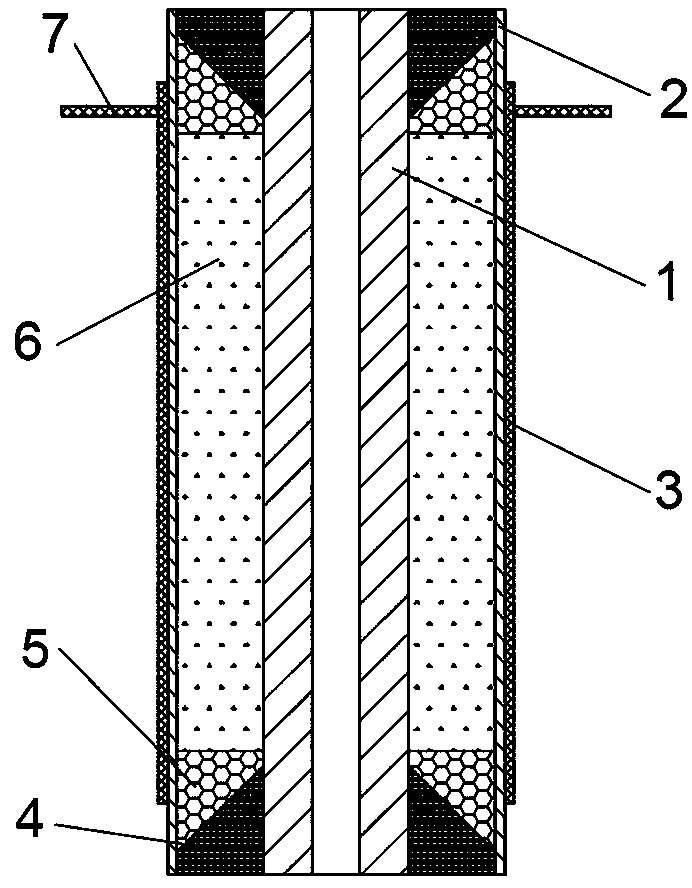

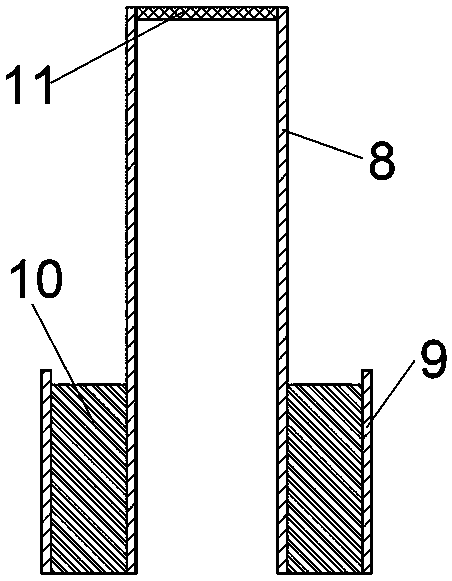

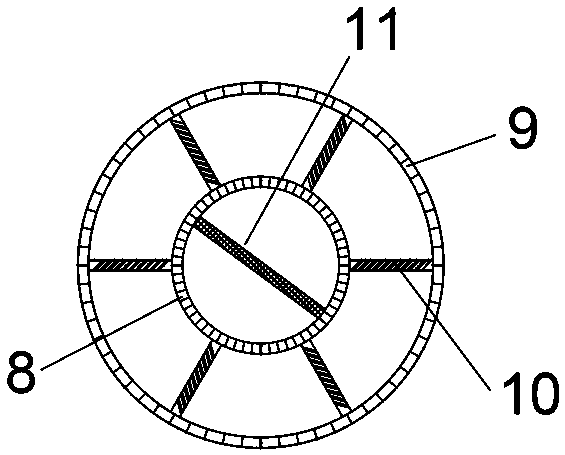

[0025] Such as figure 1 As shown, the rotary target isostatic pressing mold of the present invention includes an elastic outer mold 2 , a rigid inner mold 1 and an end plug 4 . The rigid inner mold 1 is arranged in the inner cavity of the elastic outer mold 2 , and a tubular mold cavity for filling the powder to be formed 6 is formed between the elastic outer mold 2 and the rigid inner mold 1 . The rigid inner mold 1 is used to form the central hole of the tubular rotating target, and its material is relatively hard, usually metal. The elastic outer mold 2 is the sheath of the mould, which shrinks during the isostatic pressing process to compact the powder, and its material is usually any one of neoprene, polyurethane, silicone rubber, and polyvinyl chloride. The end plugs 4 are used to seal the powder to be molded in the tubular mold cavity, usually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com