High-impact-resistance polystyrene toughening flame-retardant color masterbatch pelletizing device with uniform discharging function

A polystyrene, high-impact technology, applied in metal processing, etc., can solve the problems of lower production efficiency, uneven discharge, easy to block channels, etc., and achieve the effects of prolonging service life, uniform discharge, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

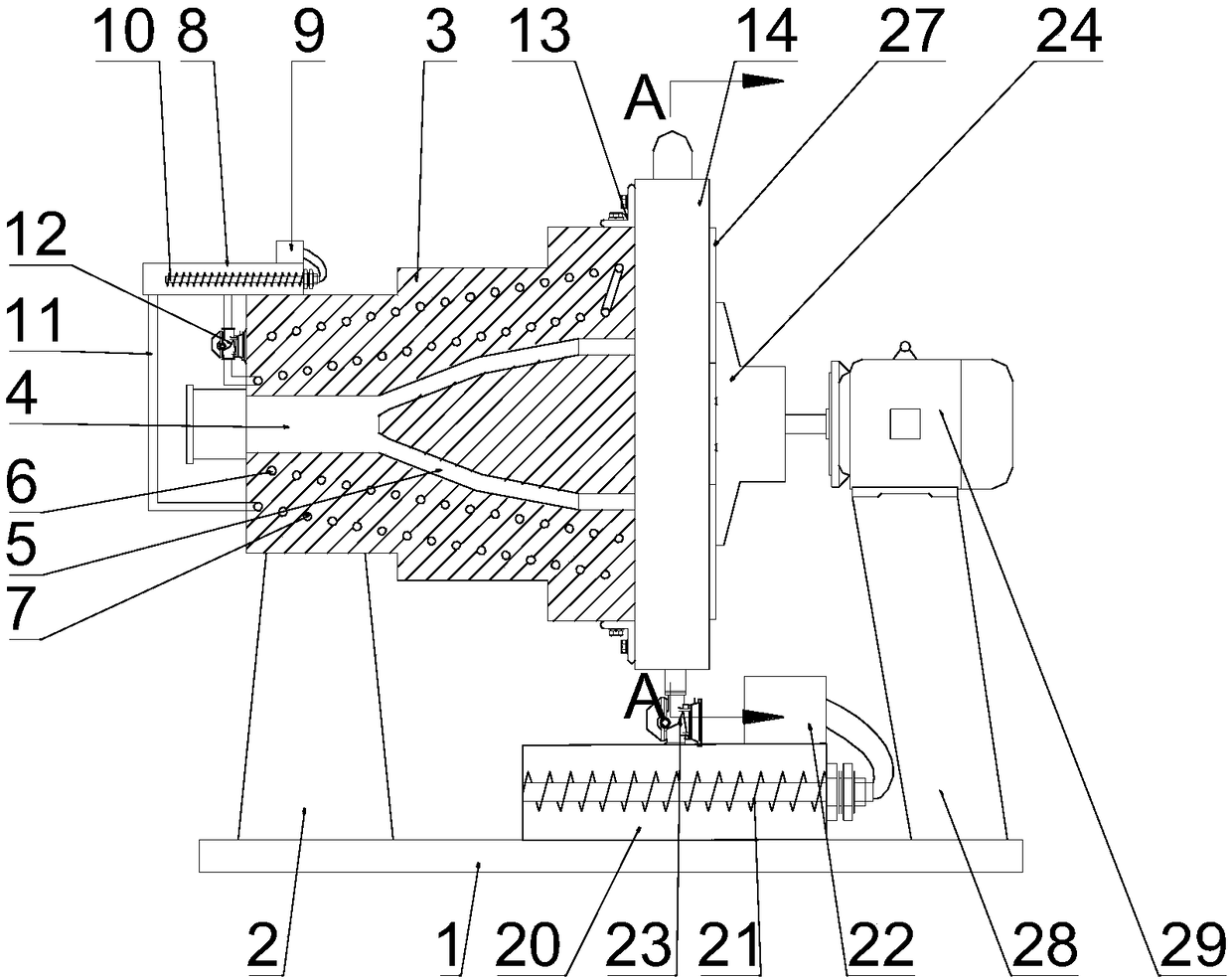

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

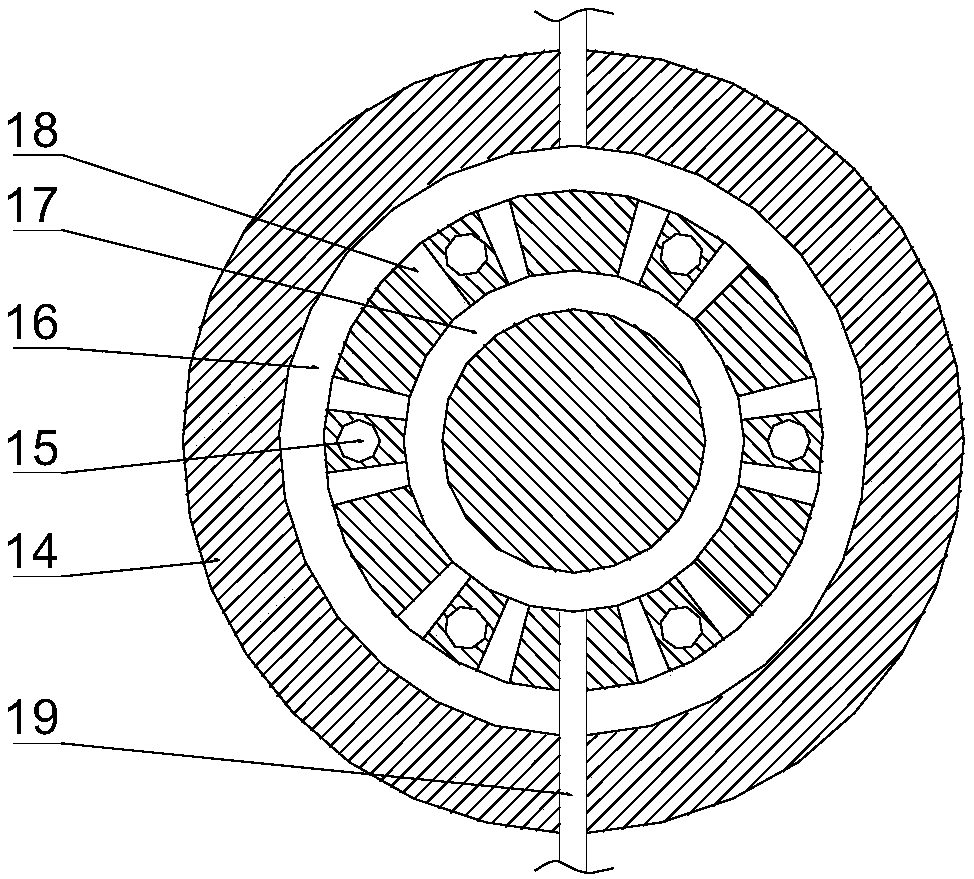

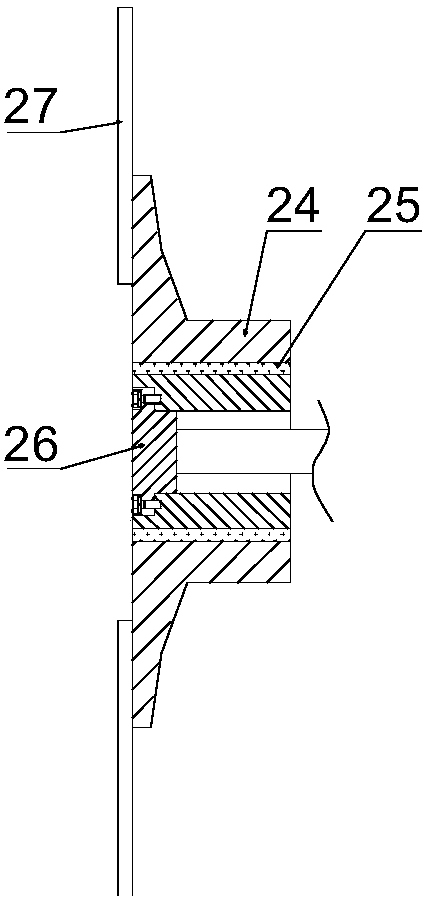

[0023] see Figure 1-3 , a high-impact polystyrene toughened flame-retardant color masterbatch cutting device with uniform discharge, comprising a base plate 1, a melting discharge head 3 installed on the base plate 1 through a first mounting frame 2, a discharge template 14, The pelletizing knife 27, the motor 29 installed on the base plate 1 through the second mounting bracket 28 and the flexible cutter head 24 installed on the output end of the motor 29 through the coupling, the inner left end middle of the melting discharge head 3 There is a main channel 4 for molten material, and the inner right end of the molten material discharge head 3 is provided with several branch channels 5 along the circumferential direction of the molten material discharge head 3, and the left end of the branch channel 5 is connected with the main channel 4 for molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com